1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

YY/T 1710-2020 English PDF (YY/T1710-2020)

YY/T 1710-2020 English PDF (YY/T1710-2020)

Regular price

$245.00

Regular price

Sale price

$245.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

YY/T 1710-2020: Disposable Abdominal Trocars

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click YY/T 1710-2020 (Self-service in 1-minute)

Newer / historical versions: YY/T 1710-2020

Preview True-PDF

Scope

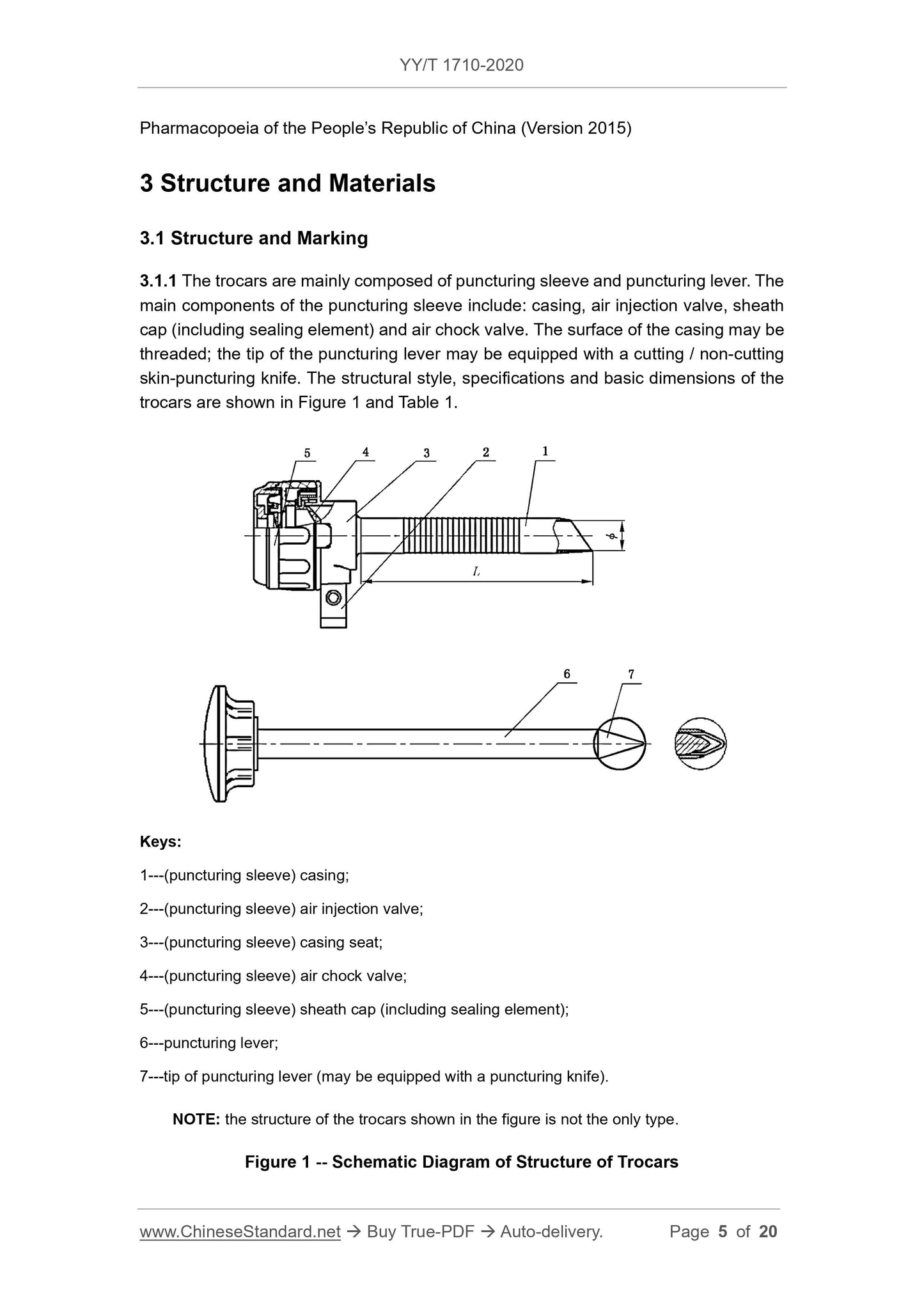

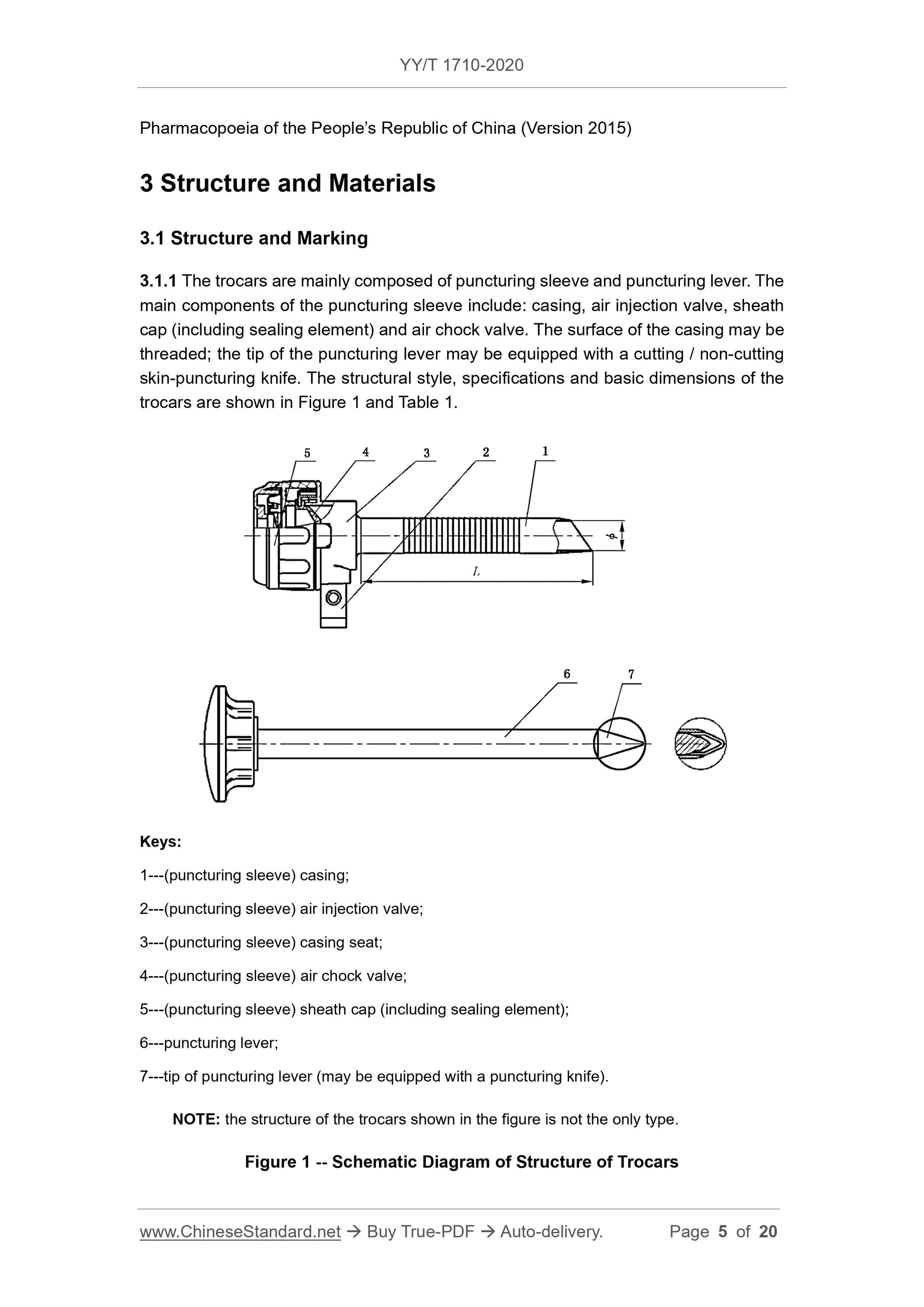

This Standard specifies the structure, materials, requirements, test methods, typeinspection, labeling, instruction manual and packaging of disposable abdominal trocars.

This Standard is applicable to disposable abdominal trocars (hereinafter referred to as

trocars) that puncture human abdominal wall tissues during laparoscopic surgery to

establish artificial pneumoperitoneum and operate surgical instrument channel.

Basic Data

| Standard ID | YY/T 1710-2020 (YY/T1710-2020) |

| Description (Translated English) | Disposable Abdominal Trocars |

| Sector / Industry | Medical Device and Pharmaceutical Industry Standard (Recommended) |

| Classification of Chinese Standard | C31 |

| Classification of International Standard | 11.040.30 |

| Word Count Estimation | 13,197 |

| Date of Issue | 2020 |

| Date of Implementation | 2021-03-01 |

| Issuing agency(ies) | State Drug Administration |

| Summary | This standard specifies the structure, materials, requirements, test methods, type inspection, labels, instructions and packaging of the disposable abdominal puncture device. This standard applies to the disposable abdominal puncture device for puncturing the human abdominal wall tissue to establish artificial pneumoperitoneum and operating the channel of surgical instruments during laparoscopic surgery. |

Share