1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

YY/T 1652-2019 English PDF (YY/T1652-2019)

YY/T 1652-2019 English PDF (YY/T1652-2019)

Regular price

$235.00

Regular price

Sale price

$235.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

YY/T 1652-2019: General technical requirements of quality control materials for in vitro diagnostic reagents

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click YY/T 1652-2019 (Self-service in 1-minute)

Newer / historical versions: YY/T 1652-2019

Preview True-PDF

Scope

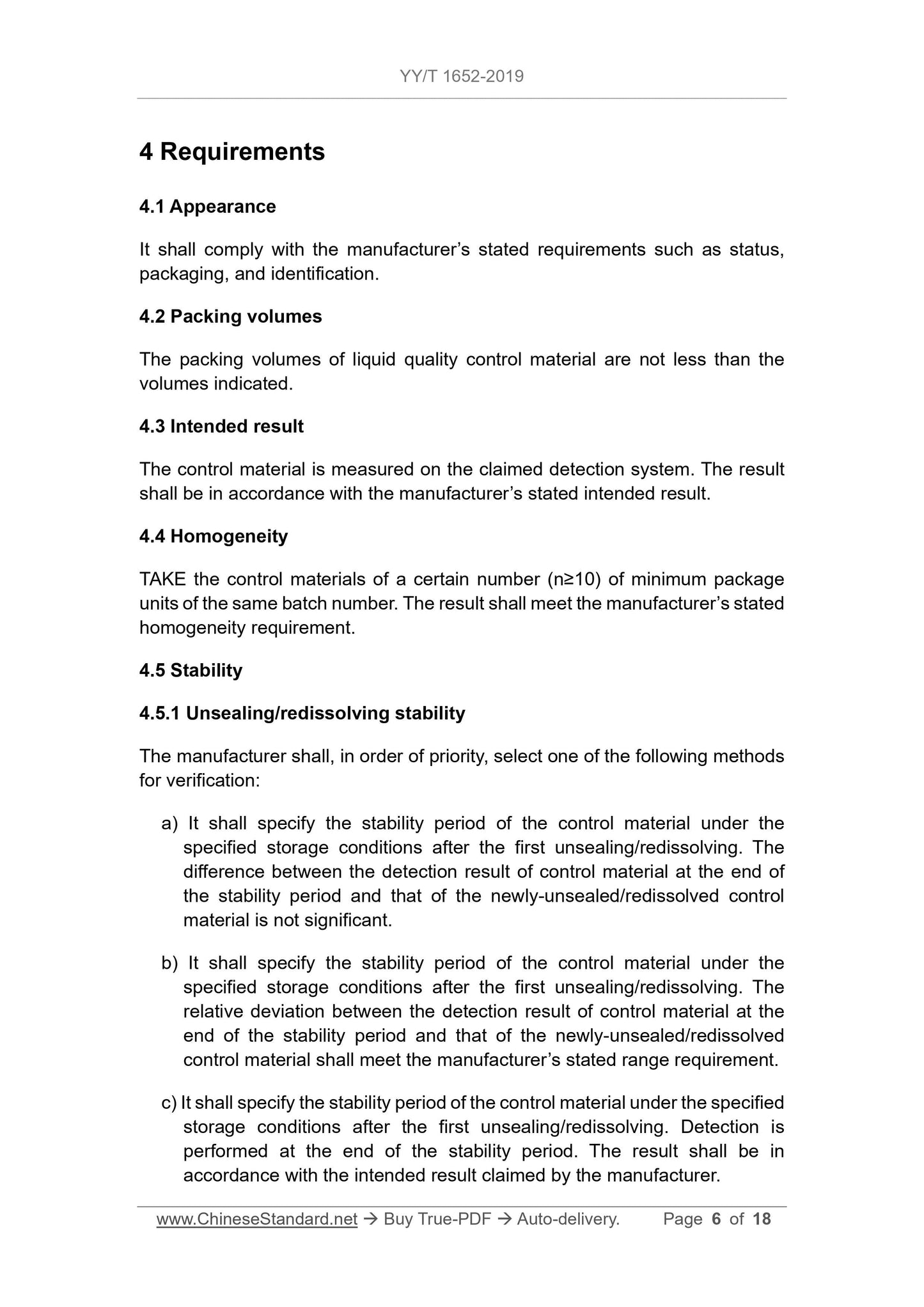

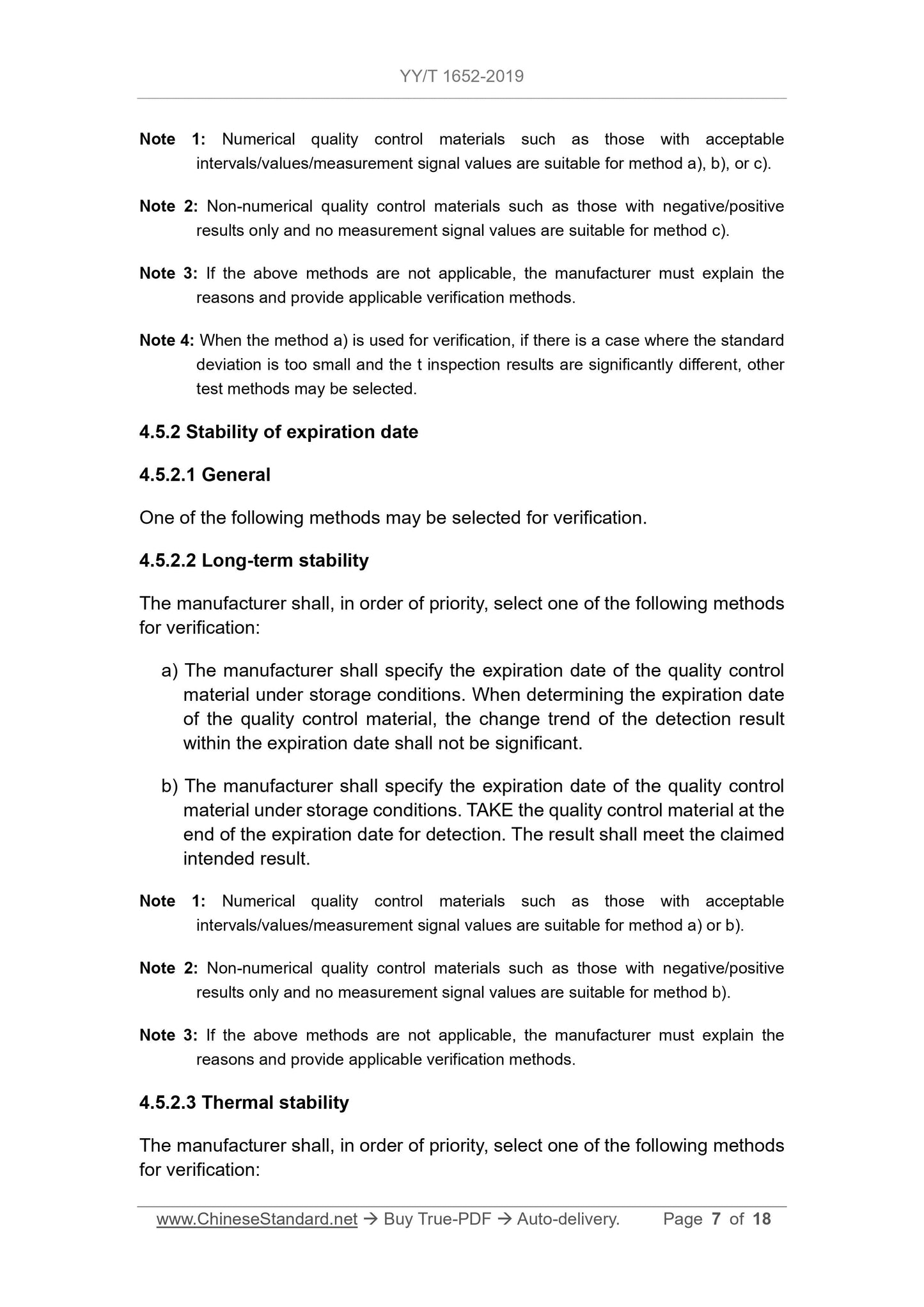

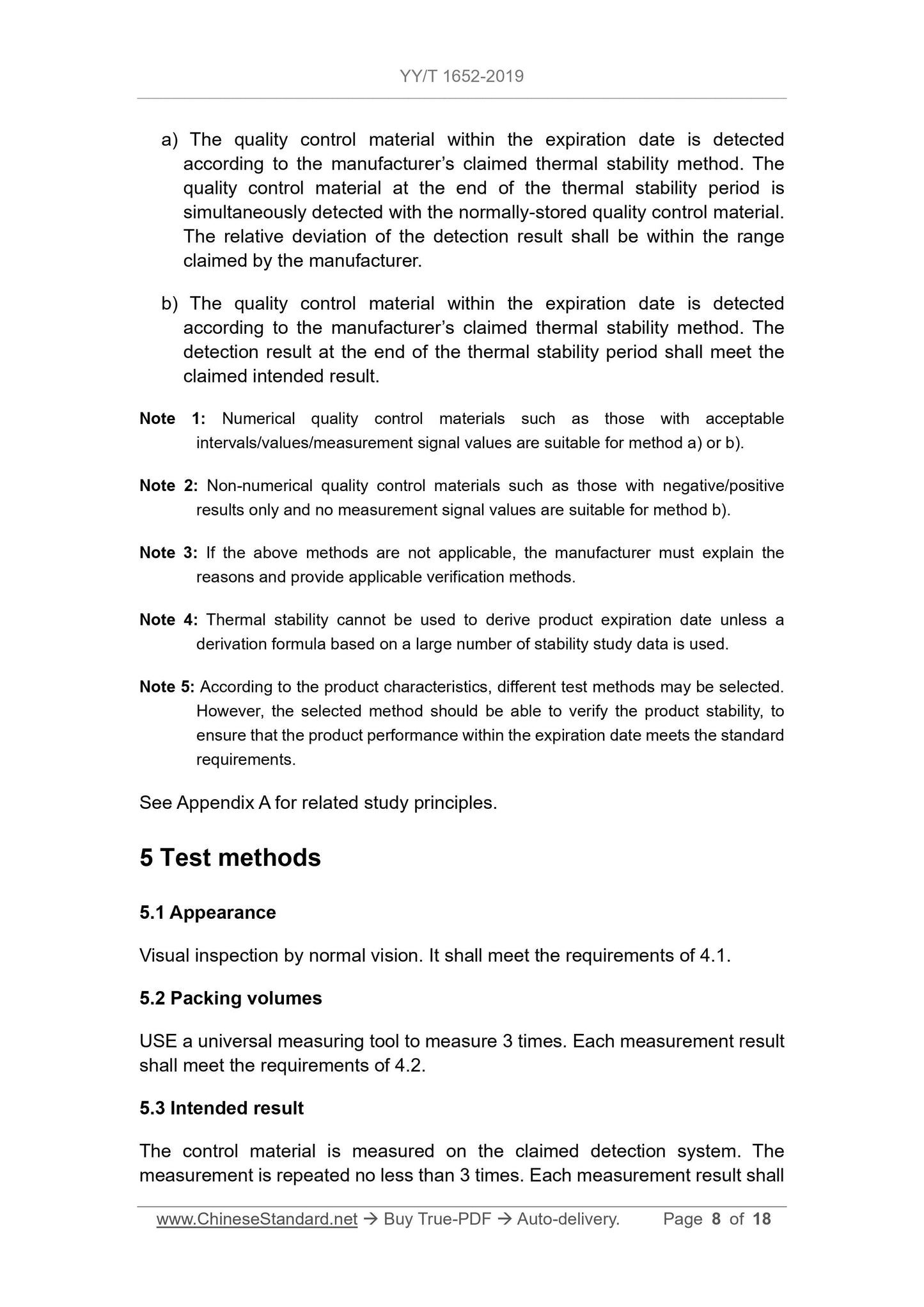

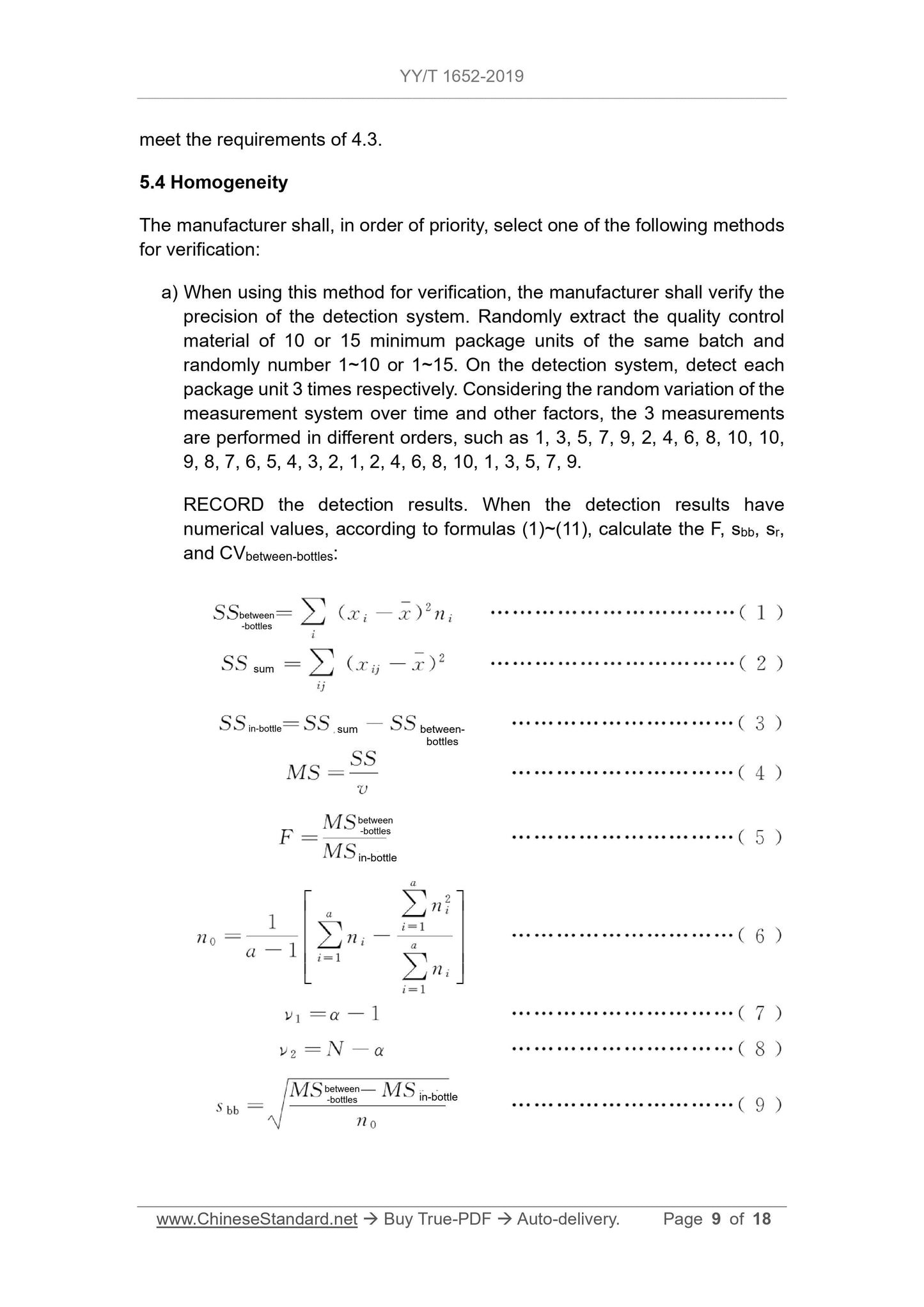

This Standard specifies the requirements, test methods, labels and instructionsfor use, packaging, transportation, and storage of quality control materials for

in vitro diagnostic reagents.

This Standard applies to quality control materials intended for the quality control

of adapted reagents.

This Standard does not apply to:

a) Quality control materials for correctness verification;

b) Quality control materials for external quality assessment;

c) Quality control materials for the detection of microorganisms,

immunohistochemistry, molecular pathology, morphology, etc.;

d) Except for the above circumstances, if still inapplicable, the manufacturer

must provide a reason.

Basic Data

| Standard ID | YY/T 1652-2019 (YY/T1652-2019) |

| Description (Translated English) | General technical requirements of quality control materials for in vitro diagnostic reagents |

| Sector / Industry | Medical Device and Pharmaceutical Industry Standard (Recommended) |

| Classification of Chinese Standard | C44 |

| Classification of International Standard | 11.100 |

| Word Count Estimation | 14,115 |

| Date of Issue | 2019 |

| Date of Implementation | 2020-06-01 |

| Issuing agency(ies) | State Drug Administration |

| Summary | This standard specifies the requirements, test methods, labels and instructions for use, packaging, transportation and storage of quality control substances for in vitro diagnostic reagents. This standard applies to the quality control substances expected to be used for the quality control of aptamer reagents. This standard does not apply to: quality control materials for correctness verification; quality control materials for inter-laboratory quality evaluation; quality control materials for microbiology, immunohistochemistry, molecular pathology, morphology, etc.; If the above situation is still not applicable, the manufacturer needs to provide reasons. |

Share