1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

YY/T 0282-2009 English PDF (YY/T0282-2009)

YY/T 0282-2009 English PDF (YY/T0282-2009)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

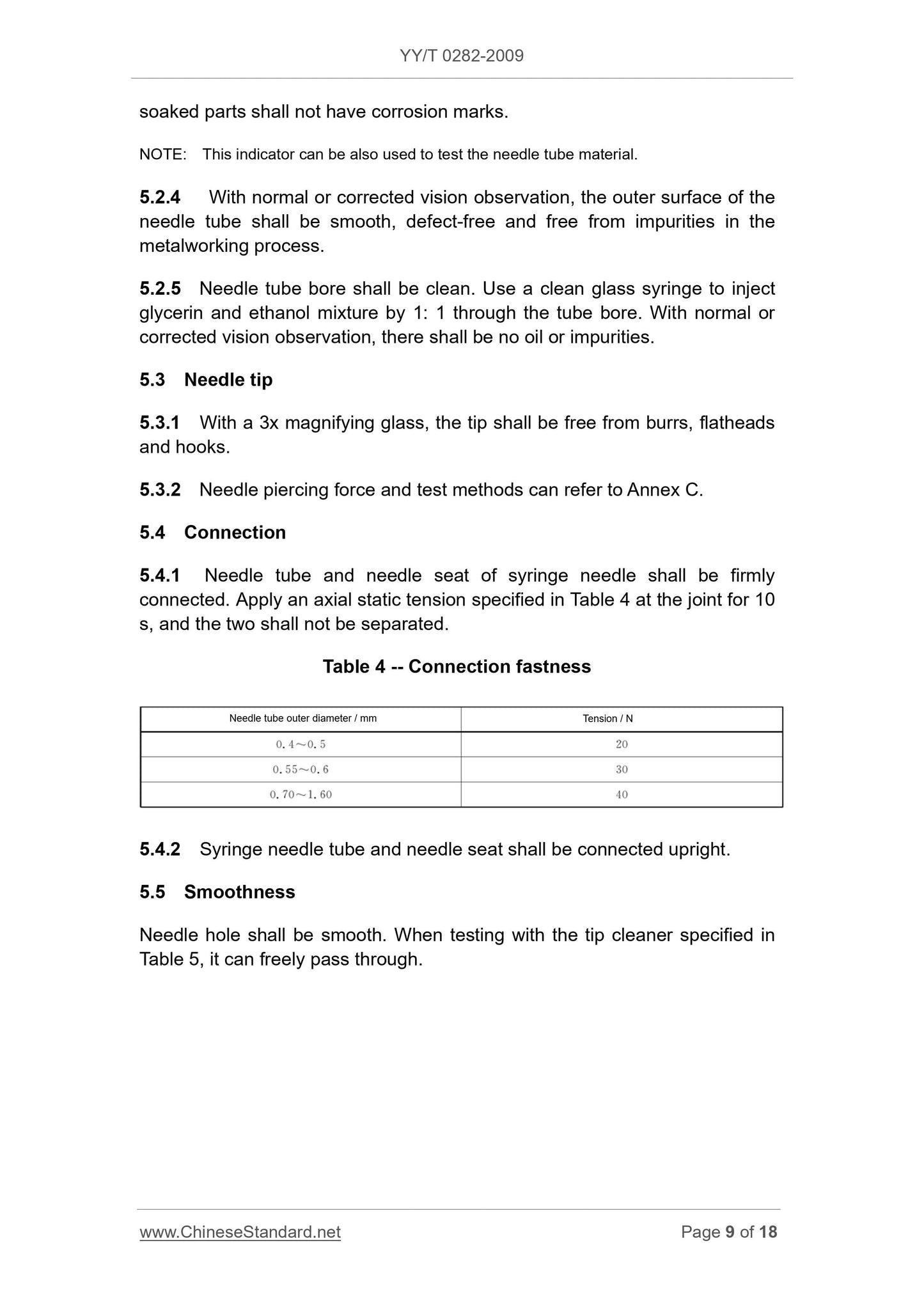

YY/T 0282-2009: Syringe needle

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click YY/T 0282-2009 (Self-service in 1-minute)

Newer / historical versions: YY/T 0282-2009

Preview True-PDF

Scope

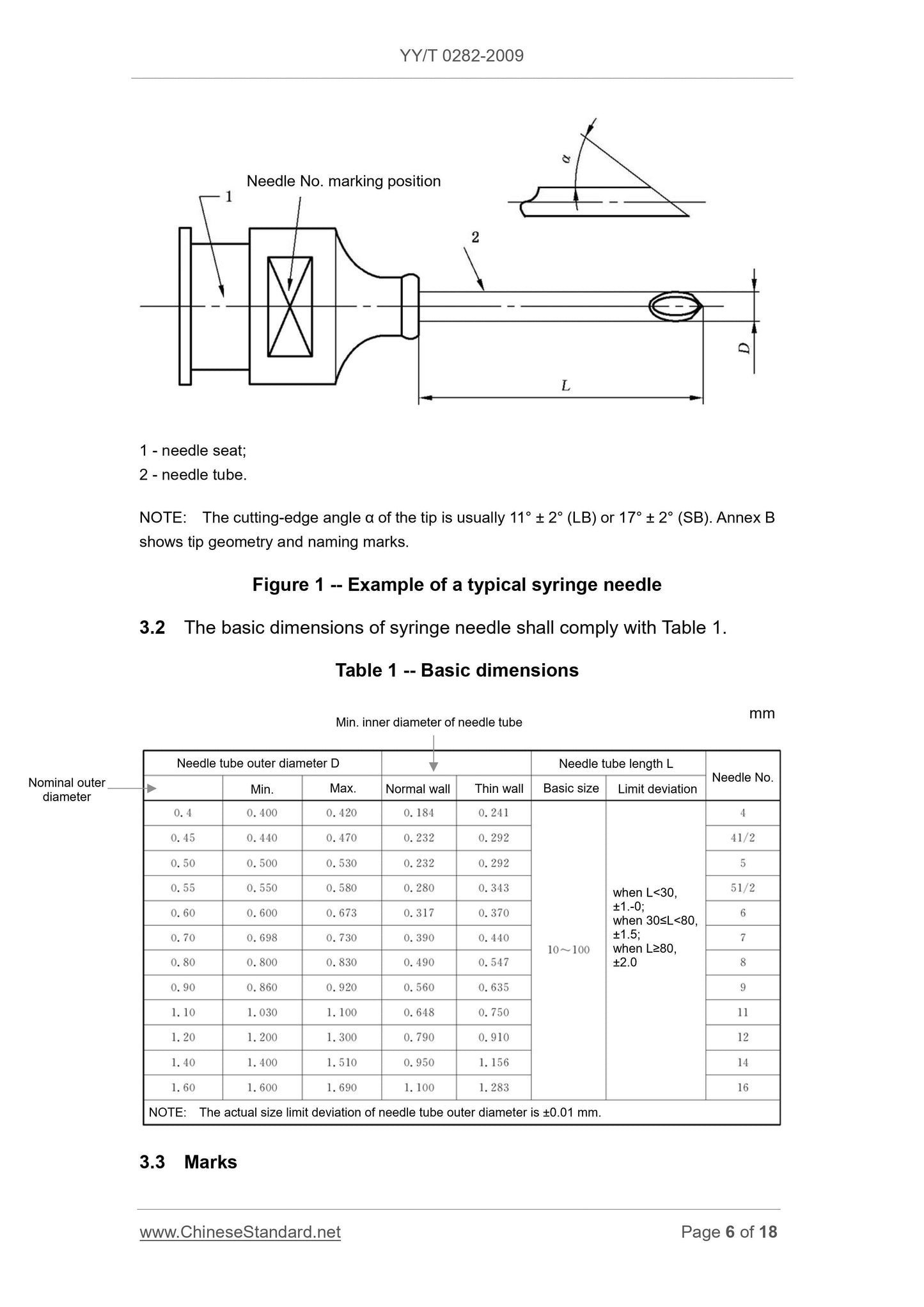

This Standard specifies the requirements for injection liquid, vaccine,anesthetic or intravenous infusion, blood transfusion needles with nominal

diameters of 0.4mm ~ 1.6mm, used for human body subcutaneous,

intradermal, muscle, oral and other parts.

Basic Data

| Standard ID | YY/T 0282-2009 (YY/T0282-2009) |

| Description (Translated English) | Syringe needle |

| Sector / Industry | Medical Device and Pharmaceutical Industry Standard (Recommended) |

| Classification of Chinese Standard | C31 |

| Classification of International Standard | 11.040.20 |

| Word Count Estimation | 14,124 |

| Date of Issue | 2009-06-16 |

| Date of Implementation | 2010-10-01 |

| Older Standard (superseded by this standard) | YY/T 0282-1995; YY 91018-1999; YY 91019-1999; YY/T 91140-1999; YY 91020-1999 |

| Quoted Standard | GB/T 191; GB/T 1962.1; GB/T 1962.2; GB 18457 |

| Regulation (derived from) | Industry standard filing Notice 2009 No. 9 |

| Issuing agency(ies) | State Food and Drug Administration |

| Summary | This standard specifies the nominal diameter 0. 4mm ~ 1. 6mm, for human subcutaneous, intradermal muscles, mouth and other parts of the injected liquid, vaccines, anesthetics or intravenous infusion, transfusion needle requirements. |

Share