1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

YY 0304-2009 English PDF

YY 0304-2009 English PDF

Regular price

$110.00

Regular price

Sale price

$110.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

YY 0304-2009: Plasma sprayed hydroxyapatite coated-titanium dental implant

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click YY 0304-2009 (Self-service in 1-minute)

Newer / historical versions: YY 0304-2009

Preview True-PDF

Scope

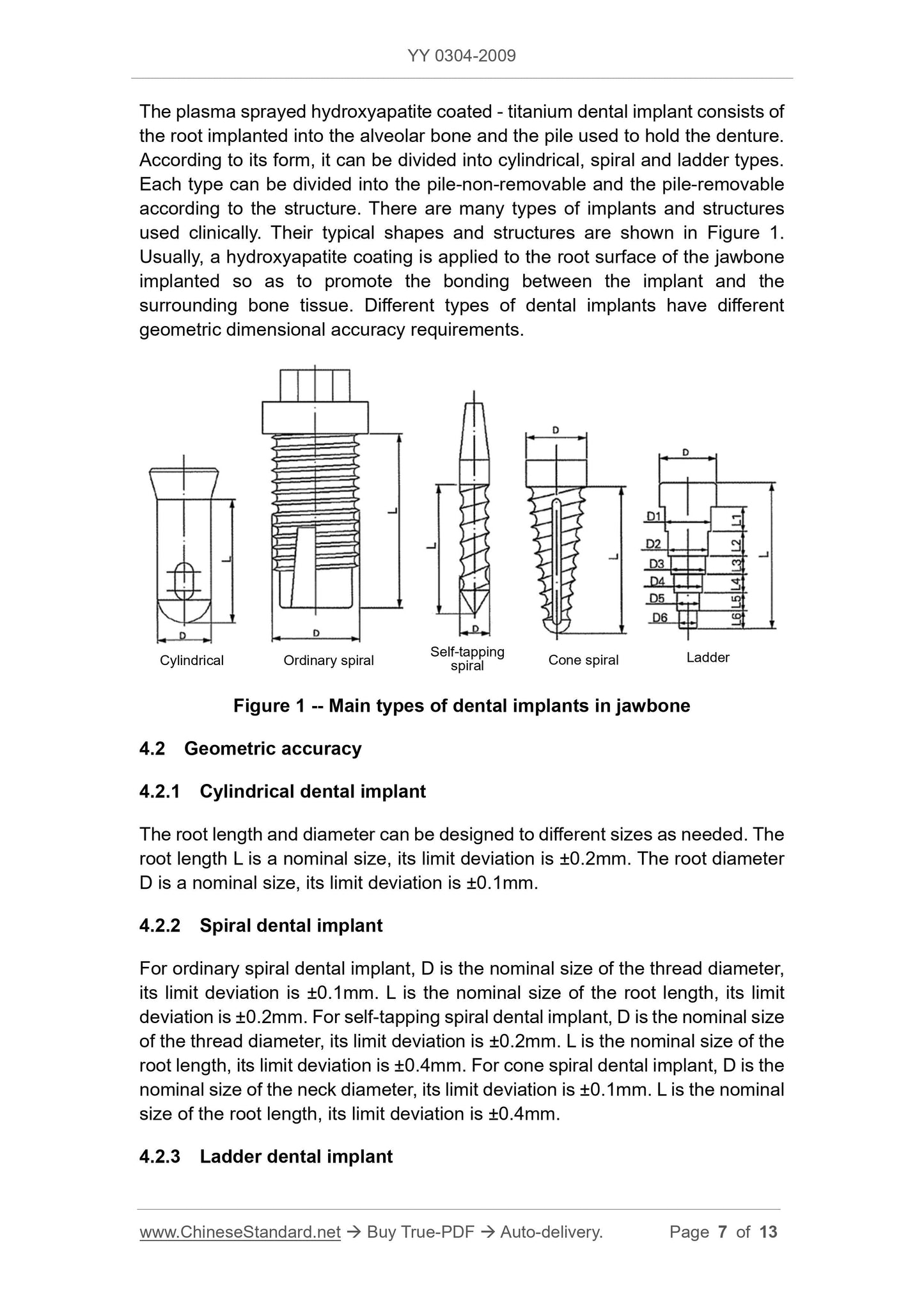

This Standard specifies the technical requirements, test methods, productclassification, marks, labels, packaging, transport and storage for plasma

sprayed hydroxyapatite coated - titanium dental implant.

This Standard is applicable to the plasma sprayed hydroxyapatite coated -

titanium dental implant that is implanted in jawbone after the loss of a teeth.

Basic Data

| Standard ID | YY 0304-2009 (YY0304-2009) |

| Description (Translated English) | Plasma sprayed hydroxyapatite coated-titanium dental implant |

| Sector / Industry | Medical Device and Pharmaceutical Industry Standard |

| Classification of Chinese Standard | C33 |

| Classification of International Standard | 11.060.10 |

| Word Count Estimation | 10,175 |

| Date of Issue | 2009-12-30 |

| Date of Implementation | 2011-06-01 |

| Older Standard (superseded by this standard) | YY 0304-1998 |

| Quoted Standard | GB/T 13810-2007; GB/T 16886.1; YY/T 0268; YY/T 0313-1998; ISO 13779.3-2008; ISO 13779.4-2002; ISO 14801-2007 |

| Adopted Standard | ISO 13779.2-2000, IDT; ISO 13779.3-2008, IDT; ISO 13779.4-2002, IDT; |

| Issuing agency(ies) | State Food and Drug Administration |

| Summary | This standard specifies the plasma sprayed hydroxyapatite coating titanium-based dental implants technical requirements, test methods, product classification, marking, labeling, packaging, transportation and storage requirements. This standard applies to dental implants jaw after missing a plasma sprayed hydroxyapatite coating titanium-based dental implants bone. |

Share