1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

YC/T 405.5-2011 English PDF (YC/T405.5-2011)

YC/T 405.5-2011 English PDF (YC/T405.5-2011)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

YC/T 405.5-2011: Tobacco and tobacco products - Determination of multi-pesticide residues - Part 5: Determination of maleic hydrazide residue - High performance liquid chromatography method

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click YC/T 405.5-2011 (Self-service in 1-minute)

Newer / historical versions: YC/T 405.5-2011

Preview True-PDF

Scope

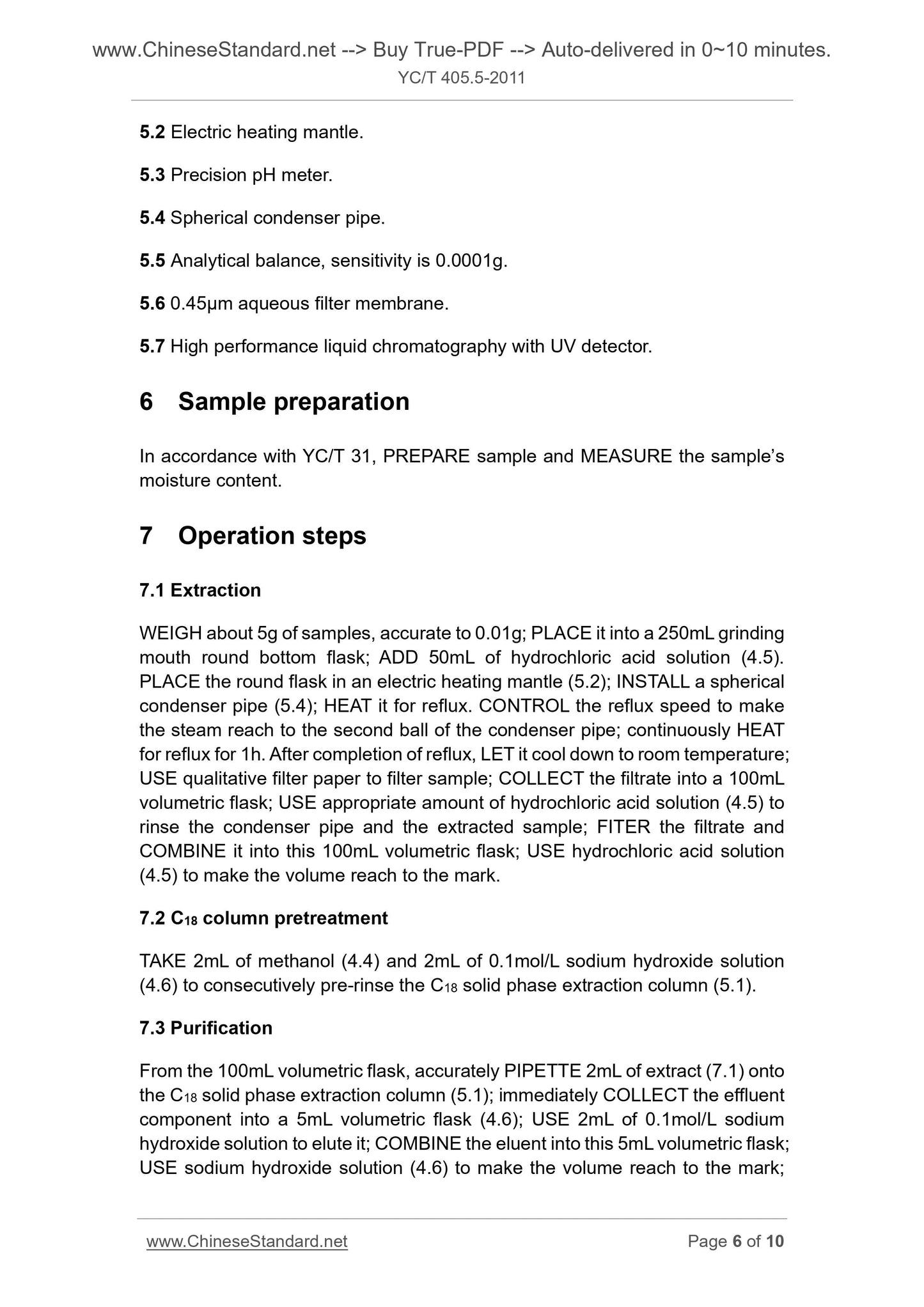

This Part of YC/T 405 specifies the high performance liquid chromatographymethod for the determination of maleic hydrazide residue in tobacco and

tobacco products.

This Part applies to the determination of maleic hydrazide pesticide residues in

tobacco and tobacco products. As for this method, the detection limit is

0.66mg/kg AND the quantitative limit is 2.18mg/kg.

Basic Data

| Standard ID | YC/T 405.5-2011 (YC/T405.5-2011) |

| Description (Translated English) | Tobacco and tobacco products - Determination of multi-pesticide residues - Part 5: Determination of maleic hydrazide residue - High performance liquid chromatography method |

| Sector / Industry | Tobacco Industry Standard (Recommended) |

| Classification of Chinese Standard | X87 |

| Classification of International Standard | 65.160 |

| Word Count Estimation | 9,922 |

| Date of Issue | 2011-08-02 |

| Date of Implementation | 2011-09-01 |

| Quoted Standard | GB/T 6682; YC/T 31 |

| Regulation (derived from) | On the approval of the State Tobacco Monopoly Bureau released Tobacco and tobacco products - Determination of chlorine continuous flow method, etc. 16 tobacco industry standard notice |

| Issuing agency(ies) | State Tobacco Monopoly Administration |

| Summary | This standard specifies the tobacco and tobacco products in the pesticide maleic hydrazide residues by high performance liquid chromatographic method. This standard applies to tobacco and tobacco products in the maleic hydrazide pesticide residues. The detection limit was 0. 66mg/kg, limit of quantification was 2. 18mg/kg. |

Share