1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YC/T 159-2002 English PDF (YC/T159-2002)

YC/T 159-2002 English PDF (YC/T159-2002)

Regular price

$80.00

Regular price

Sale price

$80.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

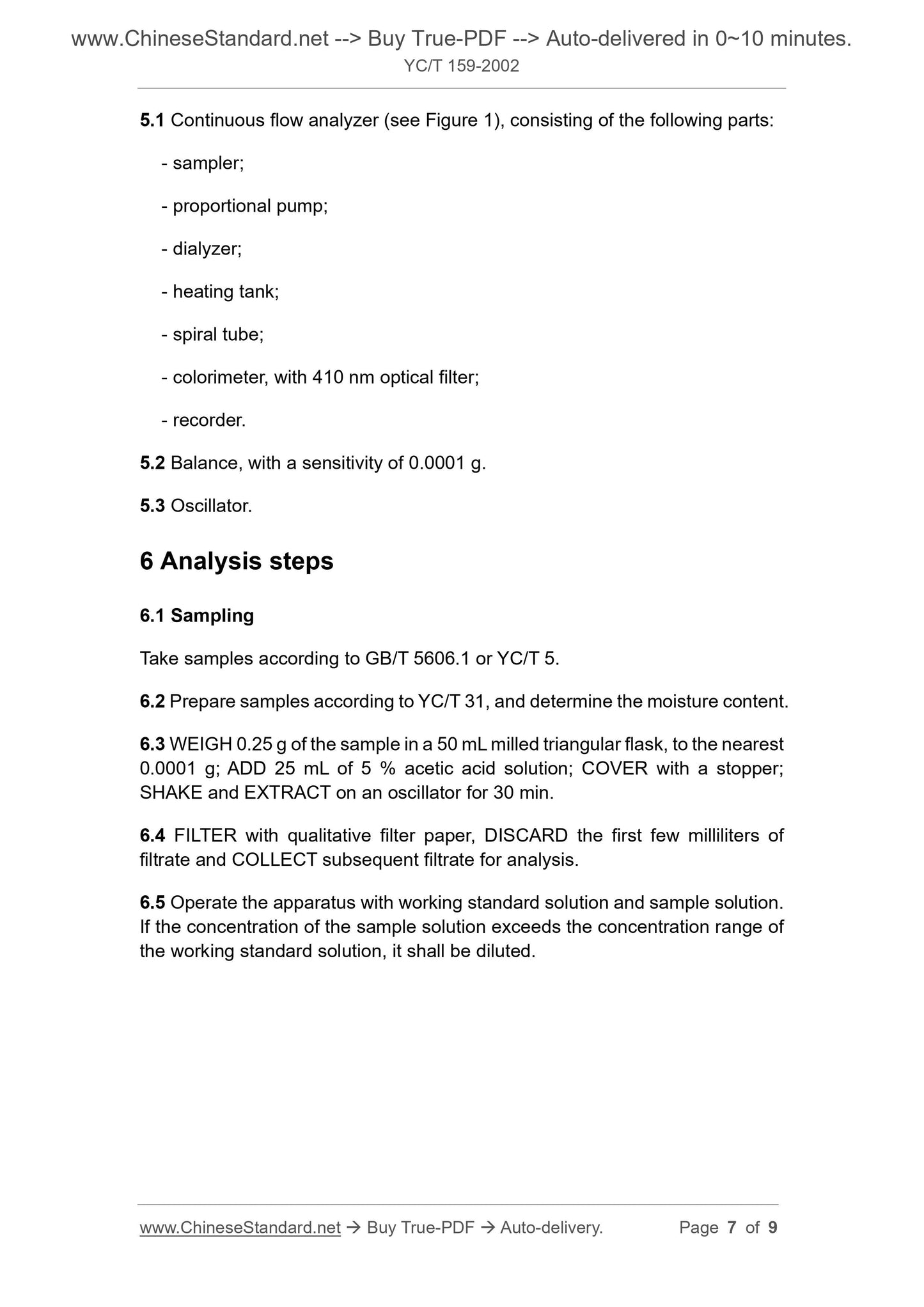

YC/T 159-2002: Tobacco and tobacco products. Determination of water soluble sugars. Continuous flow method

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click YC/T 159-2002 (Self-service in 1-minute)

Newer / historical versions: YC/T 159-2002

Preview True-PDF

Scope

This Standard specifies the determination method for water soluble sugar intobacco.

This Standard applies to tobacco and tobacco products.

Basic Data

| Standard ID | YC/T 159-2002 (YC/T159-2002) |

| Description (Translated English) | Tobacco and tobacco products. Determination of water soluble sugars. Continuous flow method |

| Sector / Industry | Tobacco Industry Standard (Recommended) |

| Classification of Chinese Standard | X87 |

| Classification of International Standard | 65.160 |

| Word Count Estimation | 6,696 |

| Date of Issue | 2002-09-12 |

| Date of Implementation | 2002-12-01 |

| Adopted Standard | CORESTA 38, MOD |

| Issuing agency(ies) | National Tobacco Monopoly Bureau |

| Summary | This standard specifies the tobacco Method for determination of water soluble sugars. This standard applies to tobacco and tobacco products. |

Share