1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

YB/T 153-2015 English PDF (YB/T153-2015)

YB/T 153-2015 English PDF (YB/T153-2015)

Regular price

$555.00

Regular price

Sale price

$555.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

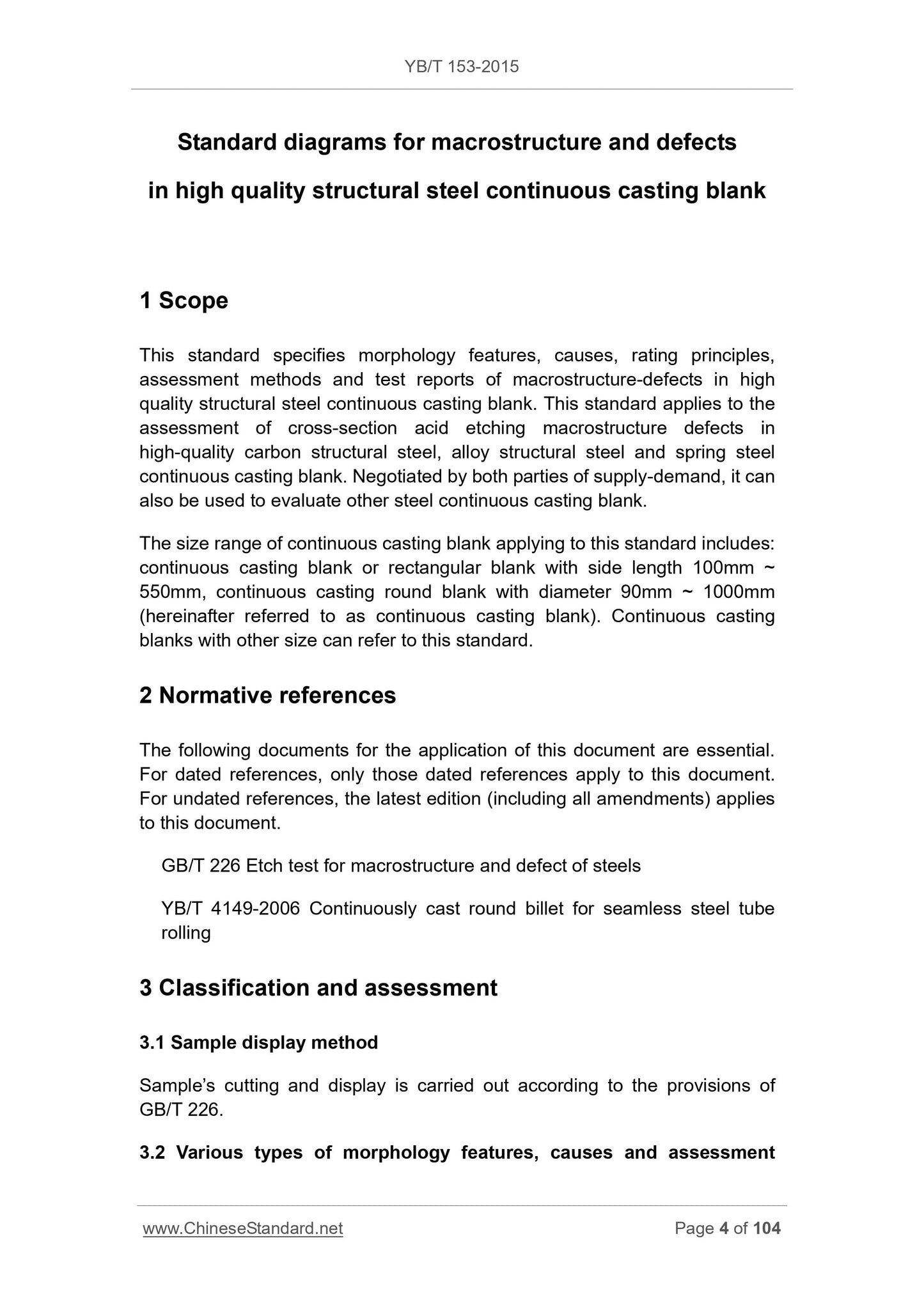

YB/T 153-2015: Standard diagrams for macrostructure and defects in high quality structural steel continuous casting blank

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click YB/T 153-2015 (Self-service in 1-minute)

Newer / historical versions: YB/T 153-2015

Preview True-PDF

Scope

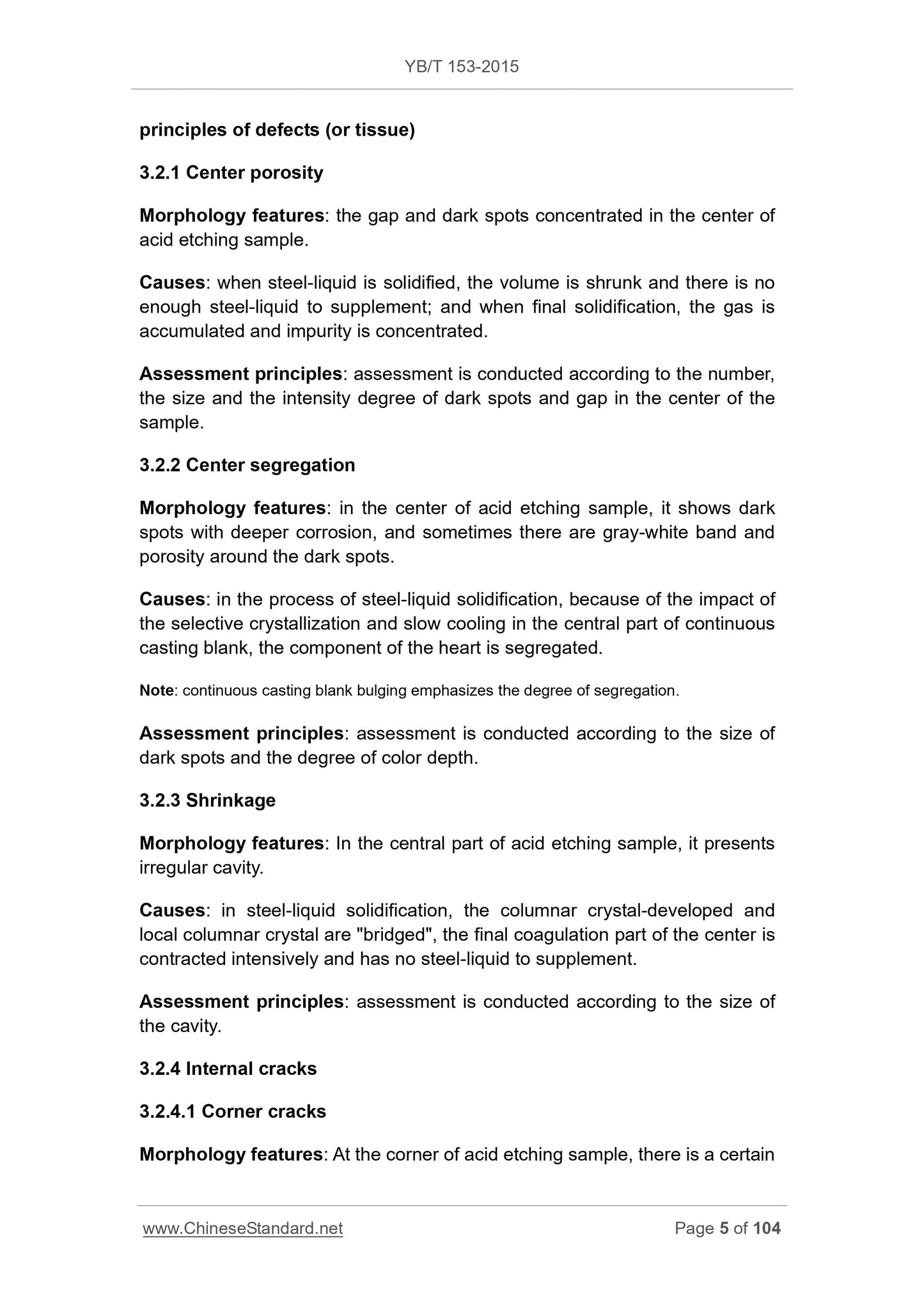

This standard specifies morphology features, causes, rating principles,assessment methods and test reports of macrostructure-defects in high

quality structural steel continuous casting blank. This standard applies to the

assessment of cross-section acid etching macrostructure defects in

high-quality carbon structural steel, alloy structural steel and spring steel

continuous casting blank. Negotiated by both parties of supply-demand, it can

also be used to evaluate other steel continuous casting blank.

The size range of continuous casting blank applying to this standard includes.

continuous casting blank or rectangular blank with side length 100mm ~

550mm, continuous casting round blank with diameter 90mm ~ 1000mm

(hereinafter referred to as continuous casting blank). Continuous casting

blanks with other size can refer to this standard.

Basic Data

| Standard ID | YB/T 153-2015 (YB/T153-2015) |

| Description (Translated English) | Standard diagrams for macrostructure and defects in high quality structural steel continuous casting blank |

| Sector / Industry | Ferrous Metallurgy Industry Standard (Recommended) |

| Classification of Chinese Standard | H24 |

| Classification of International Standard | 77.040 |

| Word Count Estimation | 99,995 |

| Date of Issue | 2015-04-30 |

| Date of Implementation | 2015-10-01 |

| Older Standard (superseded by this standard) | YB/T 153-1999 |

| Regulation (derived from) | Ministry of Industry and Information Technology Announcement (2015 No. 28) |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

Share