1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

YB/T 115-2004 English PDF (YB/T115-2004)

YB/T 115-2004 English PDF (YB/T115-2004)

Regular price

$90.00

Regular price

Sale price

$90.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

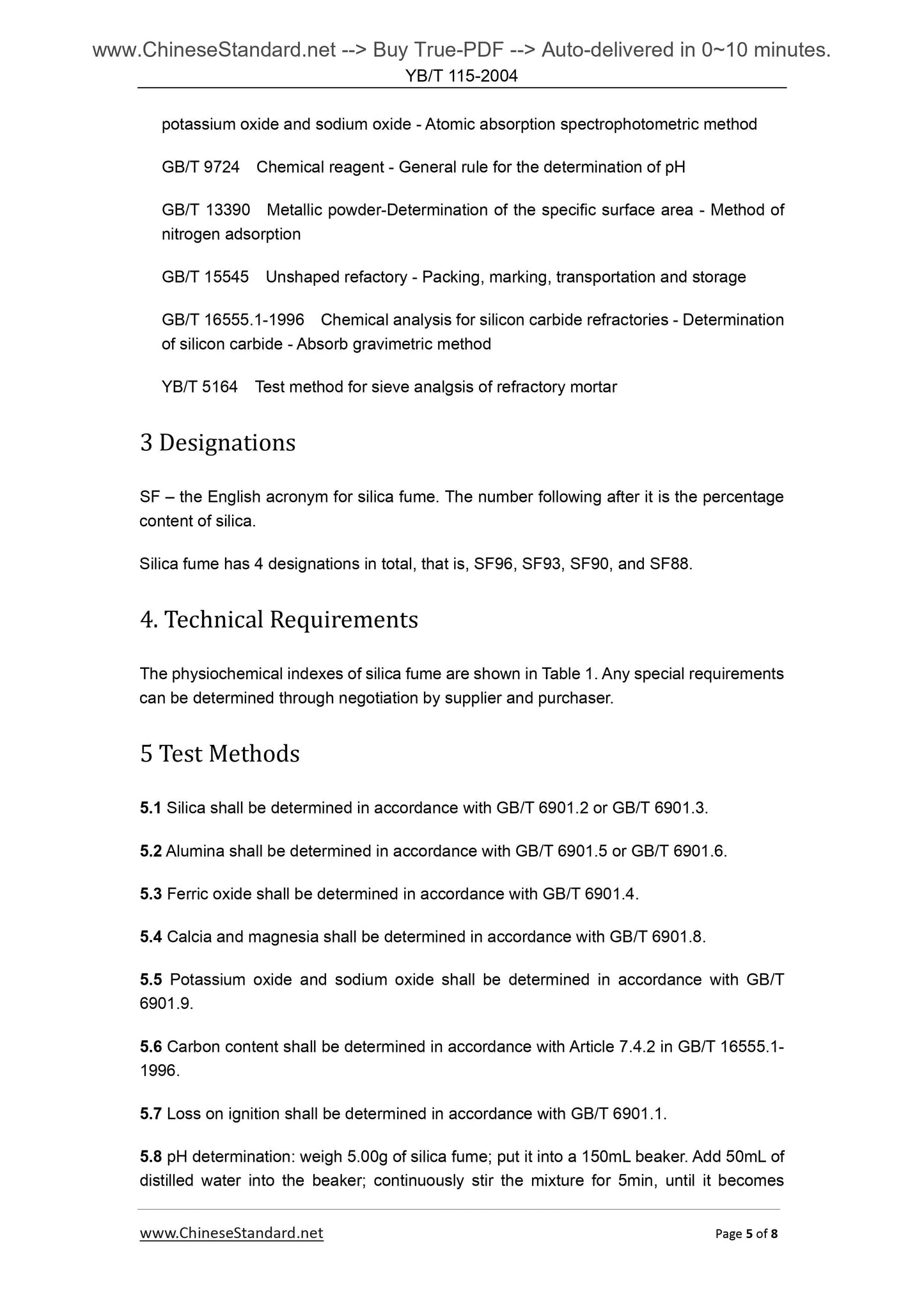

YB/T 115-2004: Silica fume for unshaped refractory

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click YB/T 115-2004 (Self-service in 1-minute)

Newer / historical versions: YB/T 115-2004

Preview True-PDF

Scope

This Standard specifies the designations, technical requirements, test methods, packaging,marking, storage, transport, and quality certificates of silica fume for unshaped refractory.

This Standard applies to that – when smelting ferrous alloys or industrial silicon, silica-

bearing fume are gathered by fume hoods; after oxidized and agglomerated, silica fume is

collected through dry dust collectors.

Basic Data

| Standard ID | YB/T 115-2004 (YB/T115-2004) |

| Description (Translated English) | Silica fume for unshaped refractory |

| Sector / Industry | Ferrous Metallurgy Industry Standard (Recommended) |

| Classification of Chinese Standard | D52 |

| Classification of International Standard | 71.060.20 |

| Word Count Estimation | 6,684 |

| Date of Issue | 6/17/2004 |

| Date of Implementation | 11/1/2004 |

| Older Standard (superseded by this standard) | YB/T 115-1997 |

| Regulation (derived from) | People's Republic of China State Development and Reform Commission Notice 2004 No. 30; Ministry of Industry and Information Technology Notice 2011 No. 25 |

| Summary | This standard specifies the use of monolithic refractories silica dioxide grades, technical requirements, test methods, inspection rules, packaging, labeling, storage, transport and quality certificates. This standard applies when ferroalloy smelting or industrial silicon, silicon-containing flue gases collected by hoods, after oxidation by dry dust collection unit cohesion collected fine silica powder. |

Share