1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

TSG 07-2019 English PDF

TSG 07-2019 English PDF

Regular price

$705.00

Regular price

Sale price

$705.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

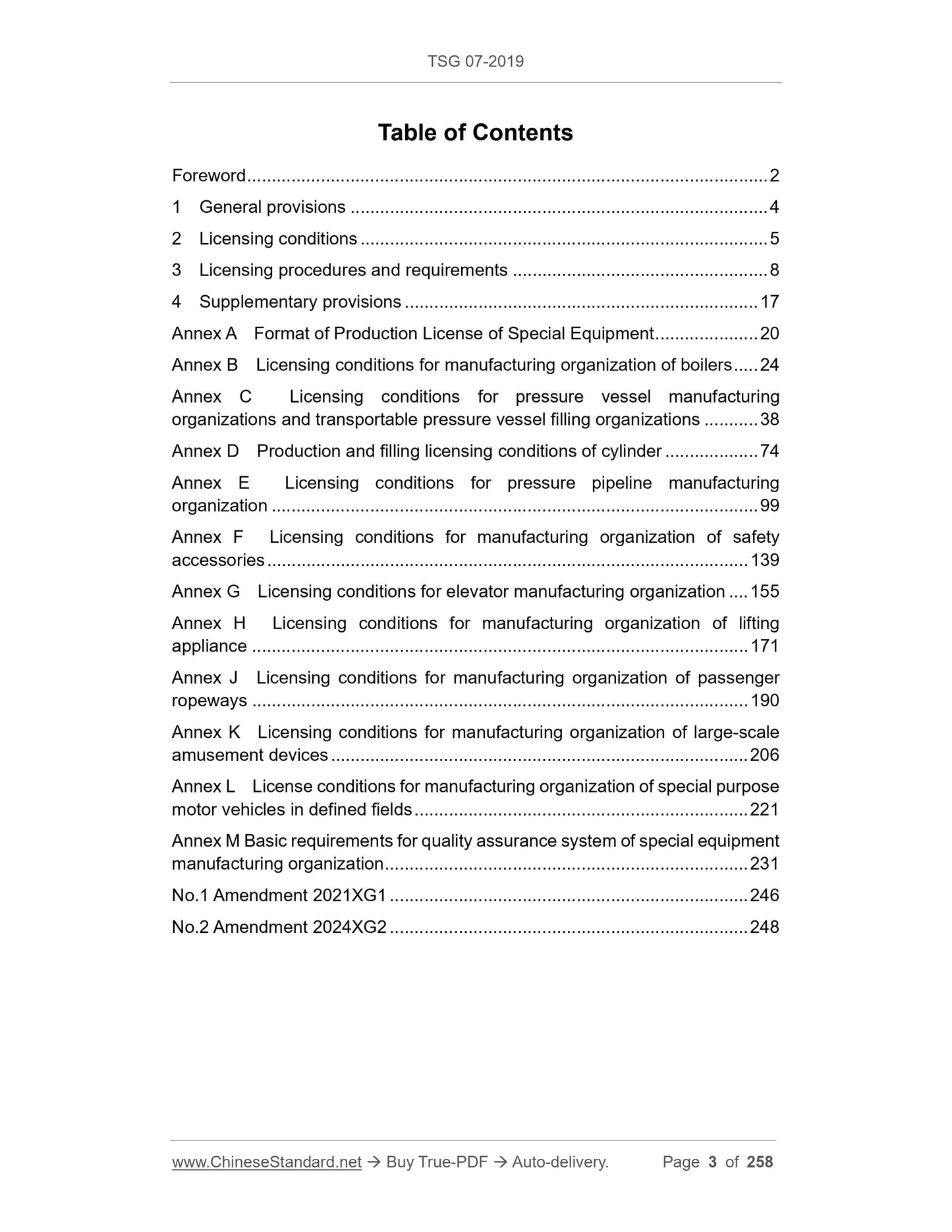

TSG 07-2019: [Including Amendments 2021XG, 2024XG2] Regulation for Production and Filling Licensing of Special Equipment

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click TSG 07-2019 (Self-service in 1-minute)

Newer / historical versions: TSG 07-2019

Preview True-PDF

Scope

1.1 Purpose and basisThe Regulation is formulated based on relevant laws and regulations such as Special

Equipment Safety Law of the People's Republic of China, Administrative Licensing Law of

the People's Republic of China and Regulations on Safety Supervision of Special

Equipment, in order to regulate the production (design, manufacturing, installation,

reformation and repair) and filling licensing of special equipment.

1.2 Application scope

The Regulation is applicable to the design, manufacturing, installation, reformation, repair,

and filling licensing of special equipment which are used in the territory of the People's

Republic of China.

1.3 Licensing entity

The agencies performing the production and filling licensing of special equipment are the

State Administration for Market Regulation and the department of provincial people's

government in charge of the special equipment safety supervision-administration (the State

Administration for Market Regulation, hereinafter referred to as ��SAMR��, and the

department of provincial people's government in charge of the special equipment safety

supervision-administration, hereinafter referred to as the provincial special equipment

safety supervision-administration department, are hereinafter collectively referred to as the

issuing authority).

1.4 Licensing catalog

The categories, items, sub-items, parameters and levels (hereinafter collectively referred

to as licensing scope) and the issuing authority of the production and filling licensing of

special equipment are implemented in accordance with the Production Licensing Catalog

of Special Equipment issued by the SAMR; the types, categories and varieties of

equipment in licensing items and sub-items are implemented in accordance with the

Special Equipment Catalog.

1.5 License and the validity period

The special equipment licenses include the "Production License of Special Equipment of

the People's Republic of China�� and the "Filling License of Transportable Pressure

Vessel/Cylinder of the People's Republic of China" (hereinafter referred to as ��licenses��,

with formats shown in Annex A), of which, the validity period is 4 years.

Share