1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

TCNFIA201-2020 English PDF

TCNFIA201-2020 English PDF

Regular price

$245.00

Regular price

Sale price

$245.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

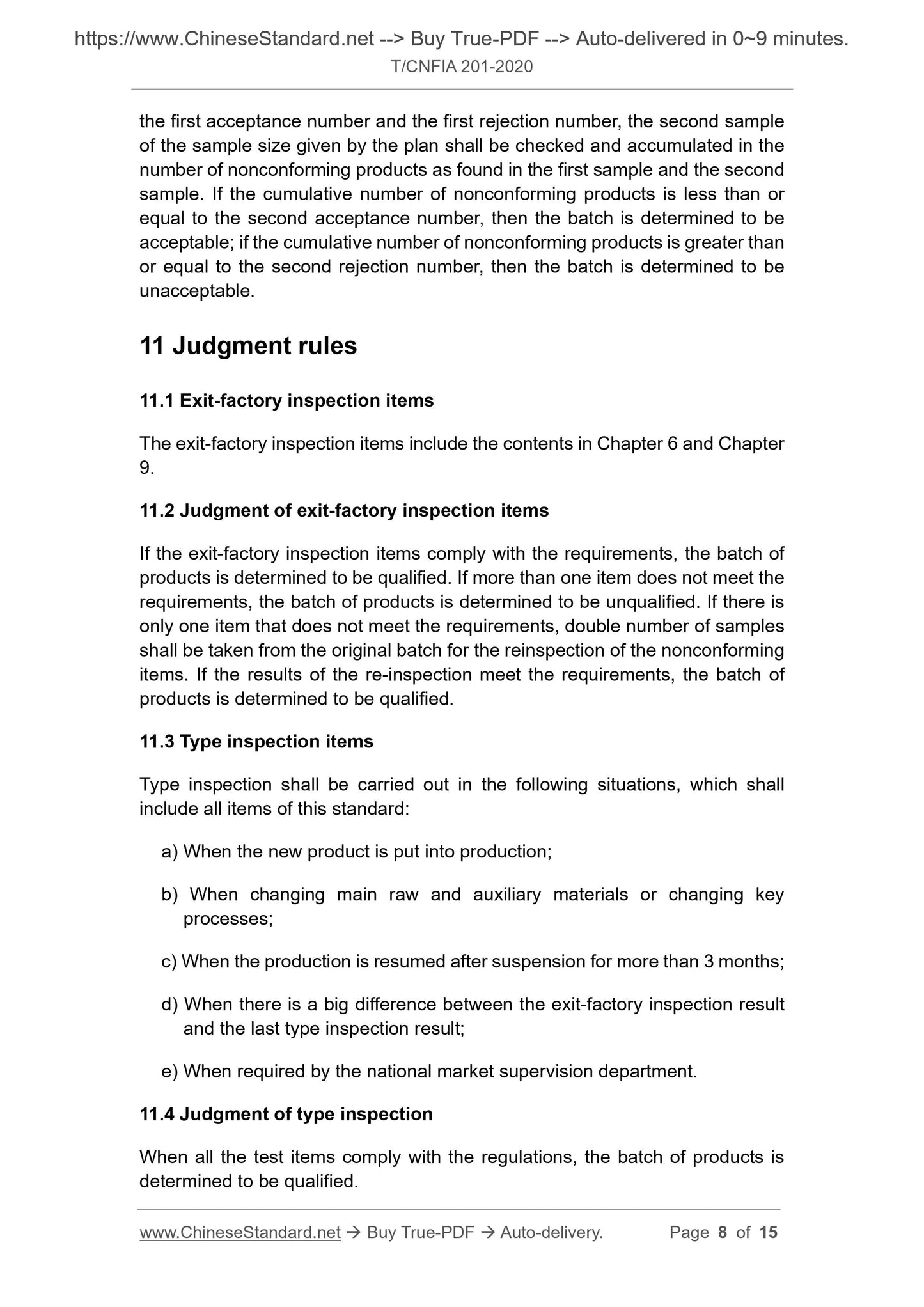

TCNFIA201-2020: Disposable paper straw for food contact

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click TCNFIA201-2020 (Self-service in 1-minute)

Newer / historical versions: TCNFIA201-2020

Preview True-PDF

Scope

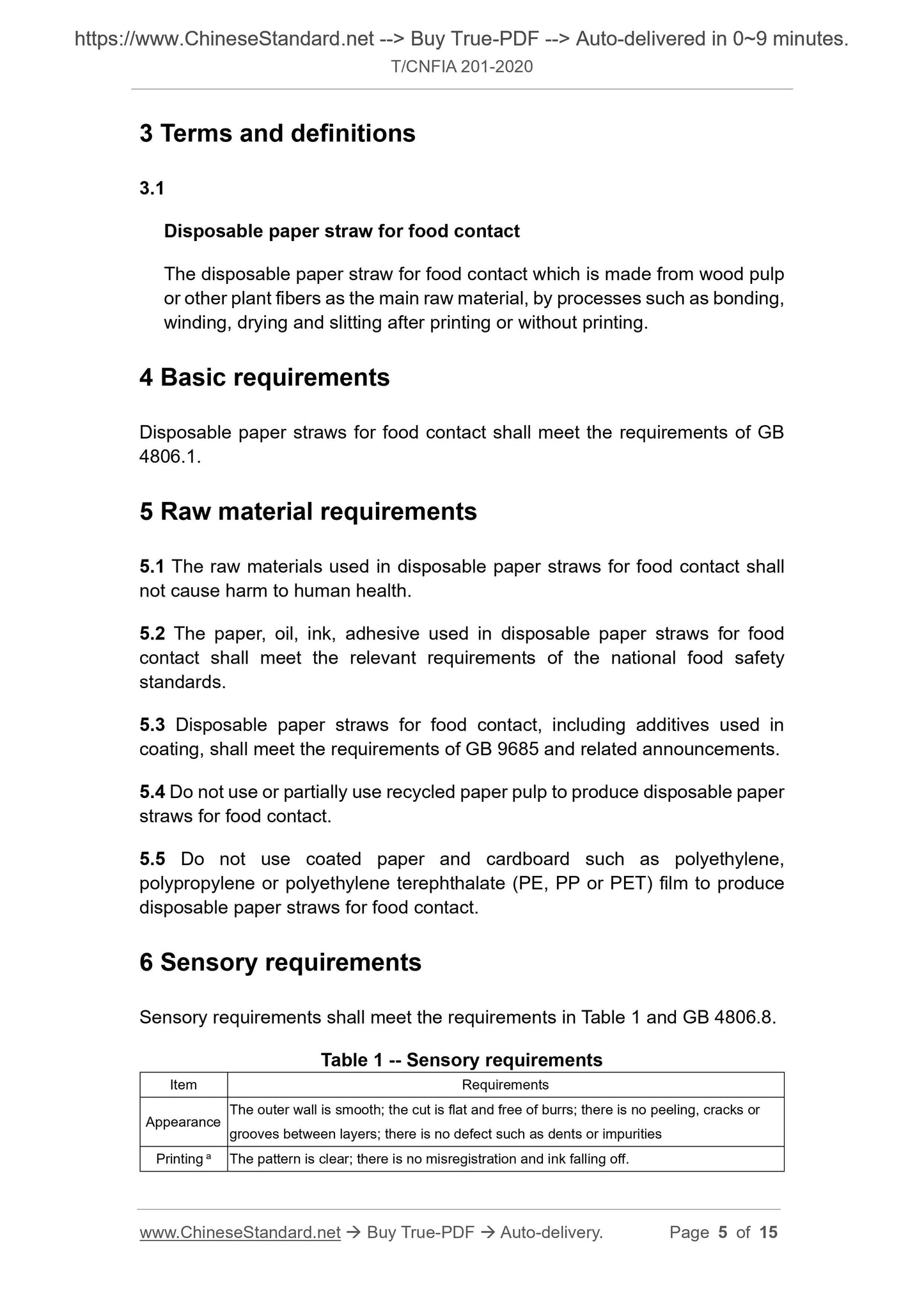

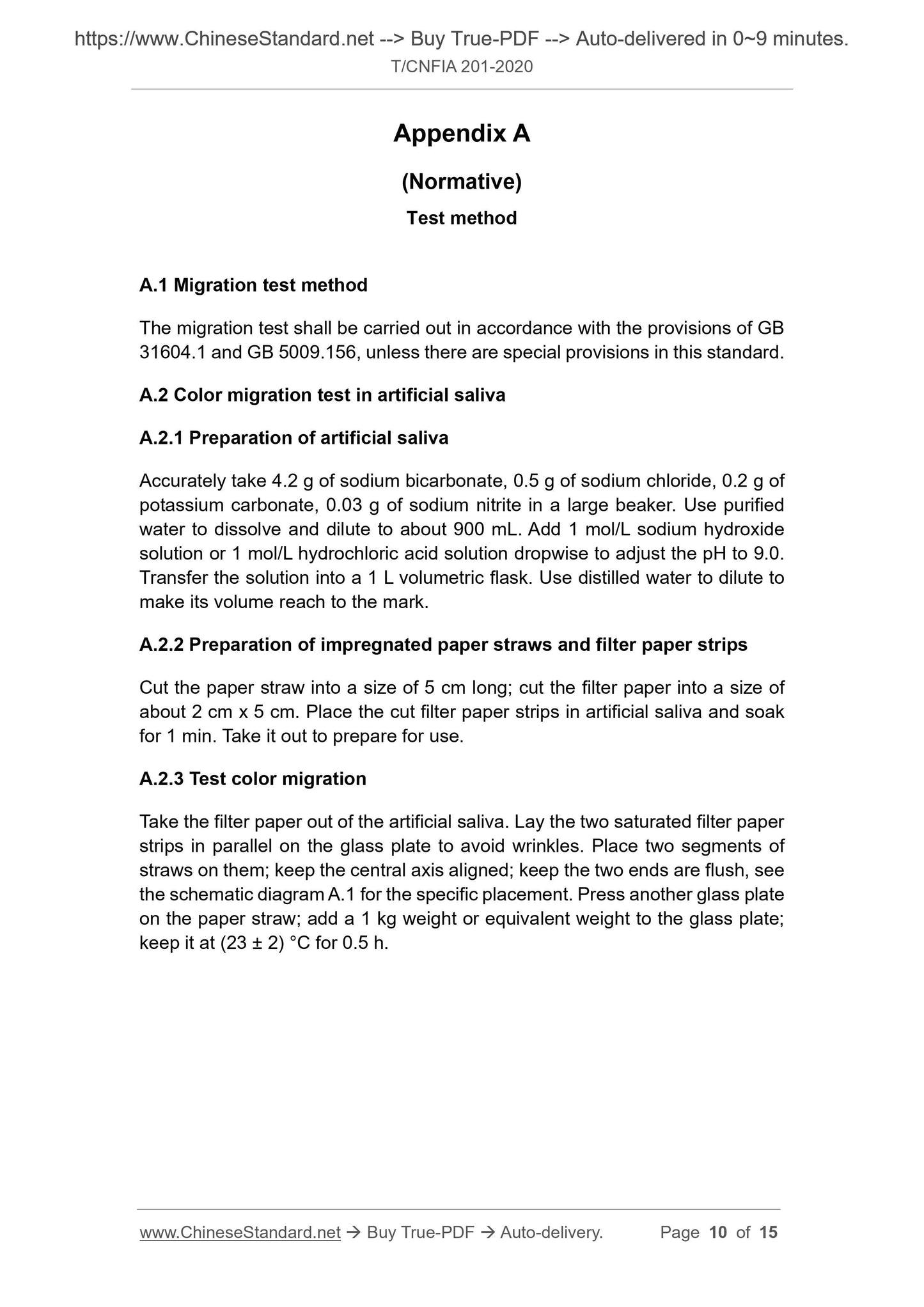

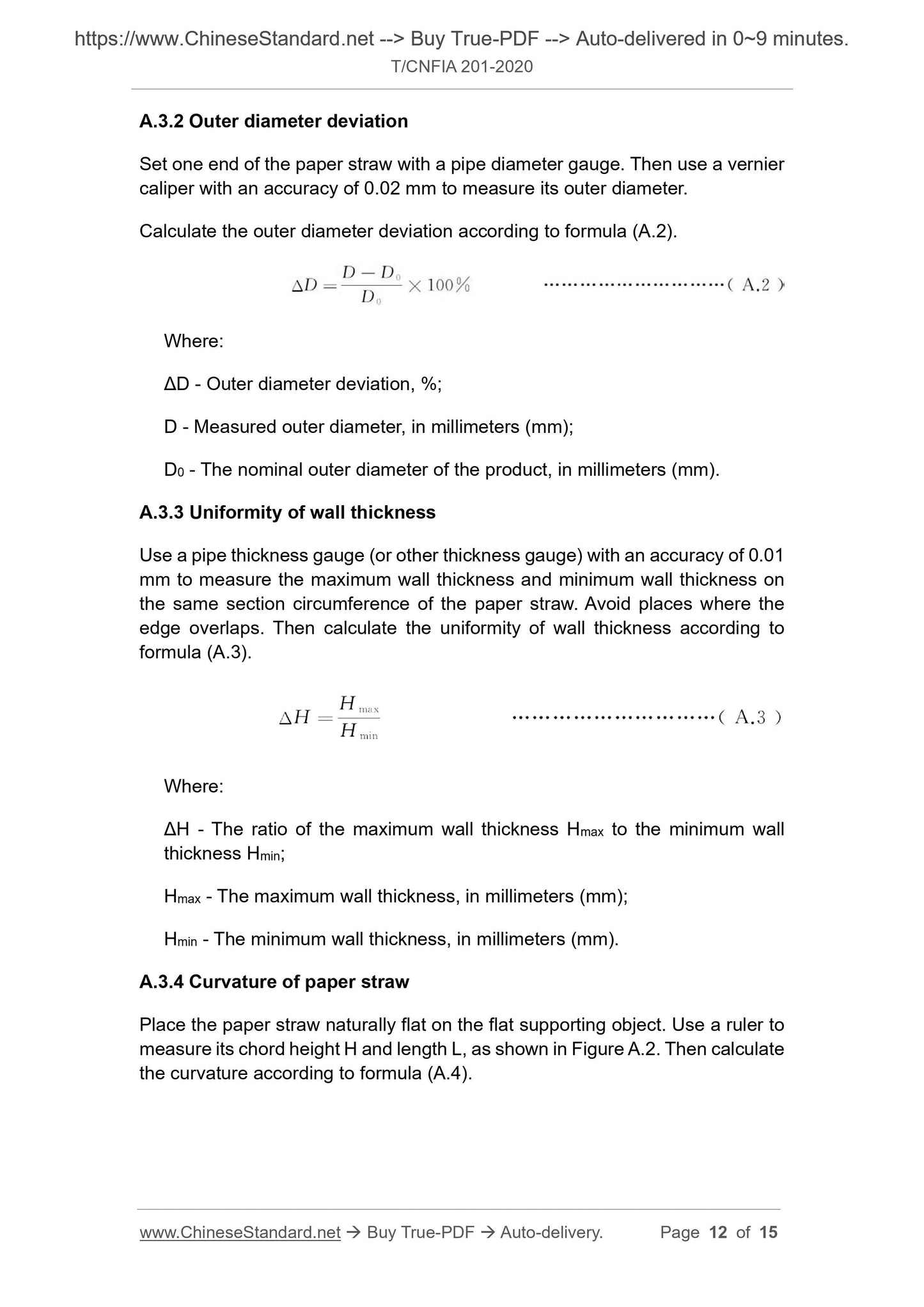

This standard specifies the basic requirements, raw material requirements,sensory requirements, physical-chemical indicators, microbiological indicators,

physical and mechanical performance requirements, sampling rules,

determination rules, packaging, storage and transportation of disposable paper

straws for food contact.

This standard applies to disposable paper straws for food contact.

Share