1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

TB/T 2344-2012 English PDF (TB/T2344-2012)

TB/T 2344-2012 English PDF (TB/T2344-2012)

Regular price

$190.00

Regular price

Sale price

$190.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

TB/T 2344-2012: [Including 2017XG1] Technical specifications for the procurement of 43 kg/m~75 kg/m rails

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click TB/T 2344-2012 (Self-service in 1-minute)

Newer / historical versions: TB/T 2344-2012

Preview True-PDF

Scope

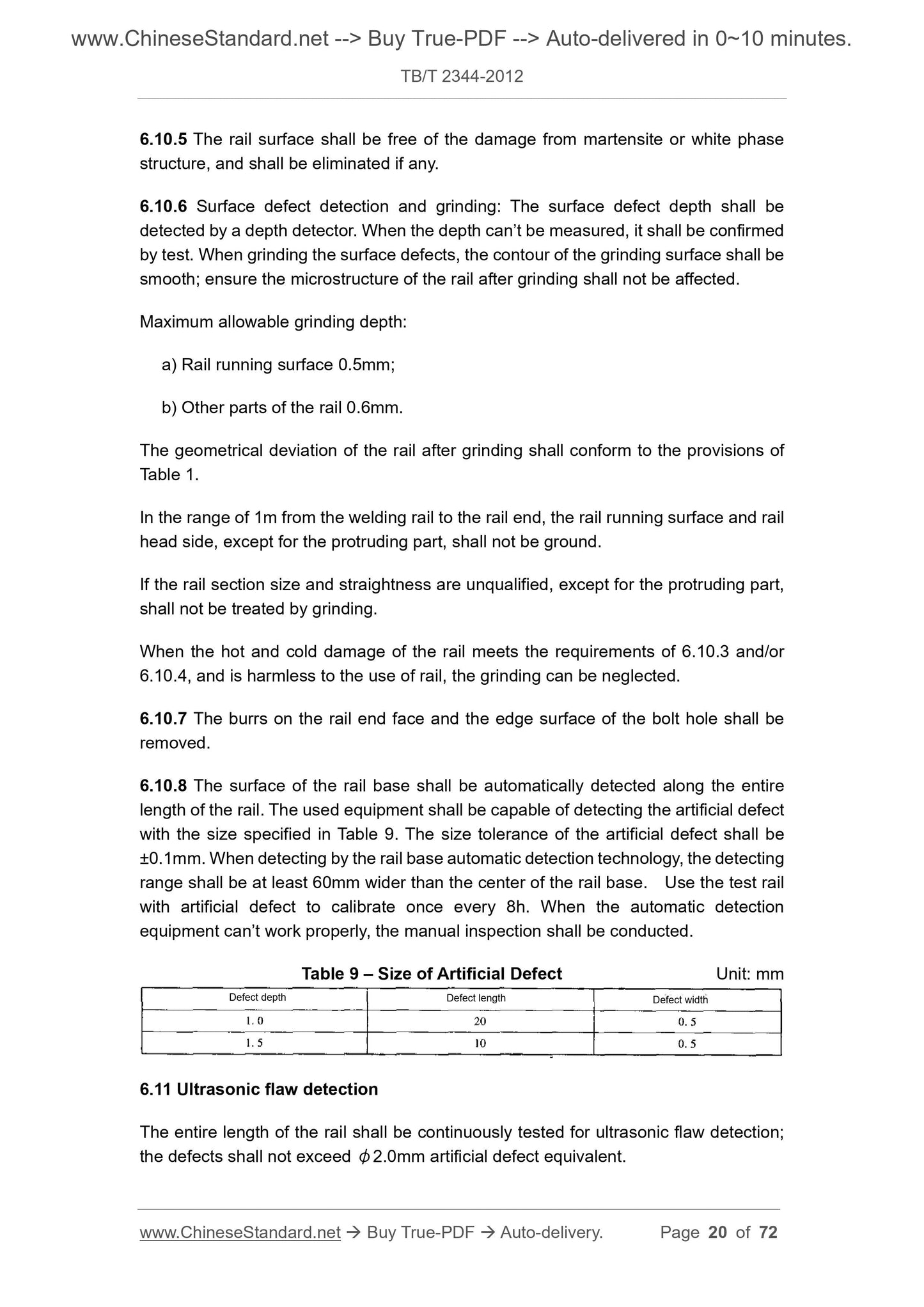

This Standard specifies the terms and definitions, ordering required information, typesize and limit deviation, technical requirements, test methods, inspection rules,

marking and quality certificate, quality assurance, and the like contents of 43kg/m ~

75kg/m rails.

This Standard is applicable to the 43kg/m ~ 75kg/m hot-rolled and online heat-treated

rails for the railway with the maximum running speed of 160km/h. this Standard can be

referred by the heat-treated rails for high-speed railways.

Basic Data

| Standard ID | TB/T 2344-2012 (TB/T2344-2012) |

| Description (Translated English) | [Including 2017XG1] Technical specifications for the procurement of 43 kg/m~75 kg/m rails |

| Sector / Industry | Railway and Train Industry Standard (Recommended) |

| Classification of Chinese Standard | S11 |

| Classification of International Standard | 45.080 |

| Word Count Estimation | 61,696 |

| Older Standard (superseded by this standard) | TB/T 2344-2003; TB/T 2635-2004 |

| Quoted Standard | GB/T 223.14; GB/T 223.49; GB/T 223.60; GB/T 223.62; GB/T 223.63; GB/T 223.68; GB/T 223.71; GB/T 223.82; GB/T 226; GB/T 228.1; GB/T 230.1; GB/T 231.1; GB/T 3075; GB/T 4161; GB/T 4336; GB/T 4340.1; GB/T 6398; GB/T 10561-2005; GB/T 11261; GB/T 13298; GB/T 19 |

| Regulation (derived from) | Railway Technology (2012) 38; industry standard filing Notice 2013 No. 7 (No. 163 overall) |

| Issuing agency(ies) | Ministry of Railways of the People's Republic of China |

| Summary | This standard specifies the 43kg/m ~ 75kg/m rail terminology and definitions, ordering the required information, type size and limit deviations, technical requirements, test methods, inspection rules, marking and quality certification, quality assurance, |

Share