1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

SN/T 3390-2012 English PDF (SN/T3390-2012)

SN/T 3390-2012 English PDF (SN/T3390-2012)

Regular price

$135.00

Regular price

Sale price

$135.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

SN/T 3390-2012: Rules for the inspection of composite laminated self-supporting bag for food packaging of plastics materials and aluminum foil

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click SN/T 3390-2012 (Self-service in 1-minute)

Newer / historical versions: SN/T 3390-2012

Preview True-PDF

Scope

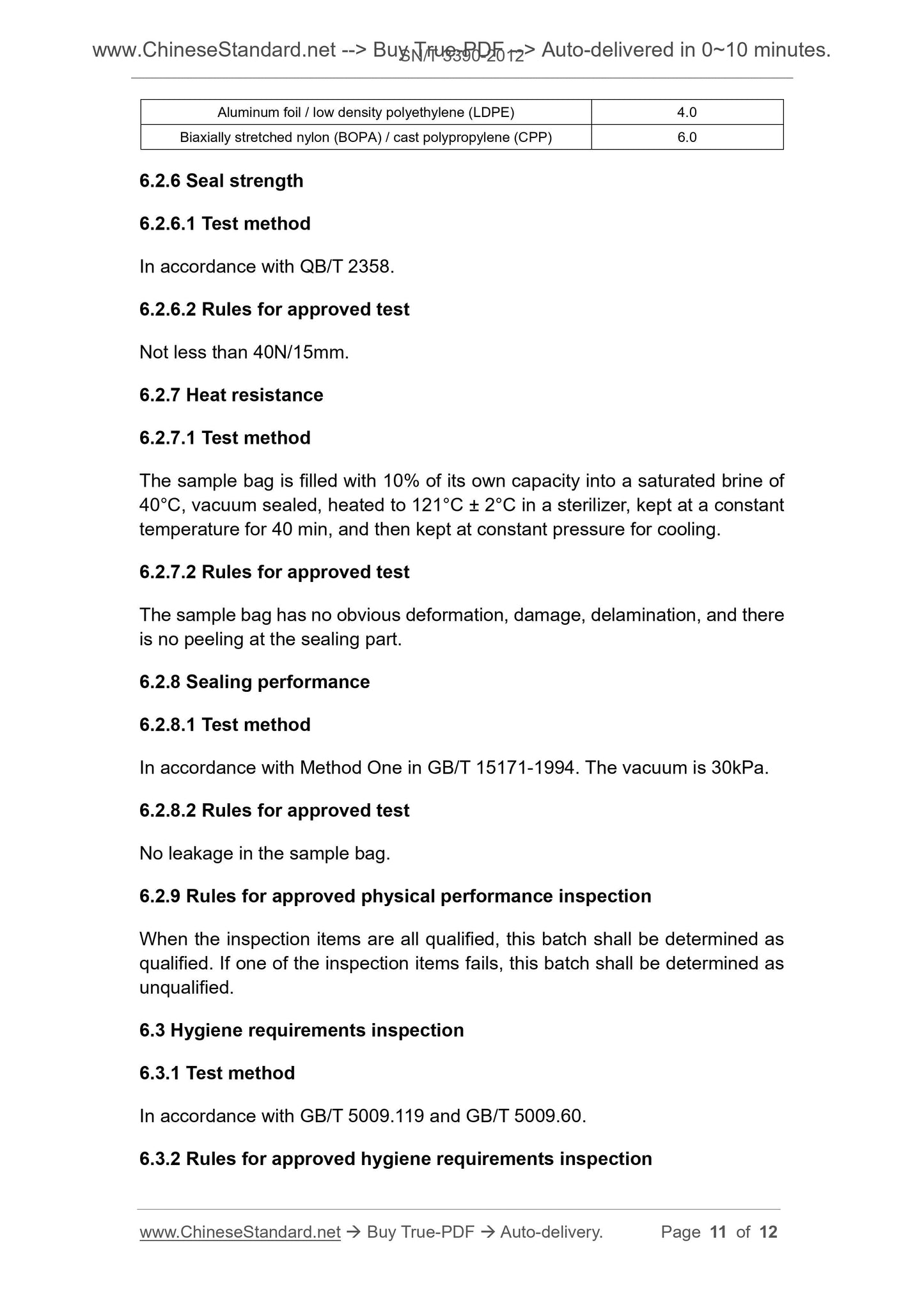

This Standard specifies the requirements, sampling, inspection and resultdetermination of composite laminated self-supporting bag for food packaging of

plastics materials and aluminum foil.

This Standard is applicable to the inspection of composite laminated self-

supporting bag for food packaging of plastics materials and aluminum foil with

volume less than 1000mL.

Basic Data

| Standard ID | SN/T 3390-2012 (SN/T3390-2012) |

| Description (Translated English) | Rules for the inspection of composite laminated self-supporting bag for food packaging of plastics materials and aluminum foil |

| Sector / Industry | Commodity Inspection Standard (Recommended) |

| Classification of Chinese Standard | X08 |

| Classification of International Standard | 67.250 |

| Word Count Estimation | 10,133 |

| Quoted Standard | GB/T 2828.1; GB/T 4857.5; GB/T 5009.60; GB/T 5009.119; GB/T 6672; GB/T 6673; GB/T 7707; GB/T 8808; GB 9683; GB/T 15171-1994; QB/T 2358 |

| Regulation (derived from) | National Quality Inspection (2012) 777; industry standard filing Notice 2013 No. 4 (No. 160 overall) |

| Issuing agency(ies) | General Administration of Customs |

| Summary | This standard specifies the food in plastic, aluminum foil pouches requirements, sampling, testing and results of determination. This standard applies to the following capacity of 1 000 mL plastic food, aluminum foil pouches test. |

Share