1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

SL 470-2010 English PDF

SL 470-2010 English PDF

Regular price

$85.00

Regular price

Sale price

$85.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

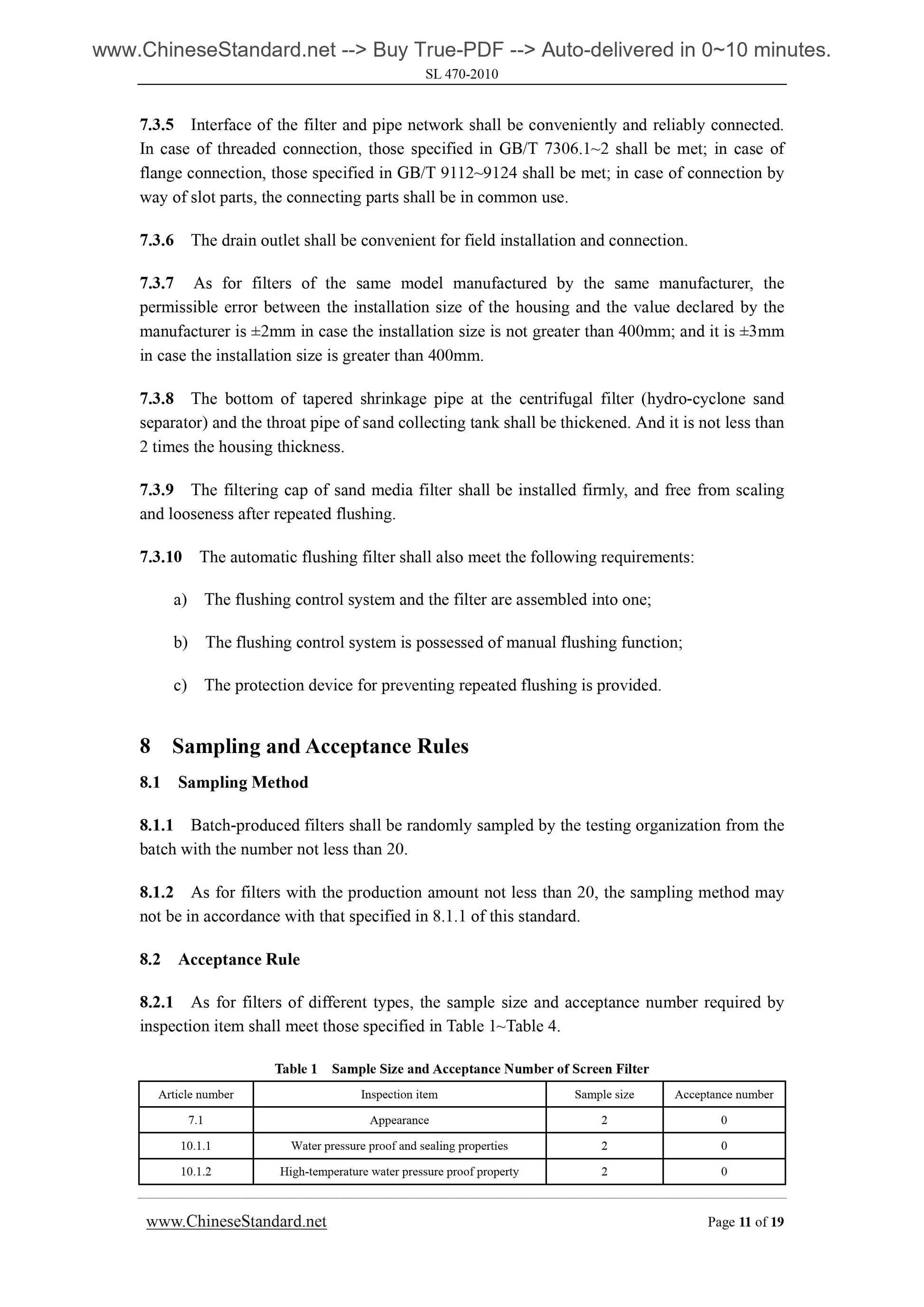

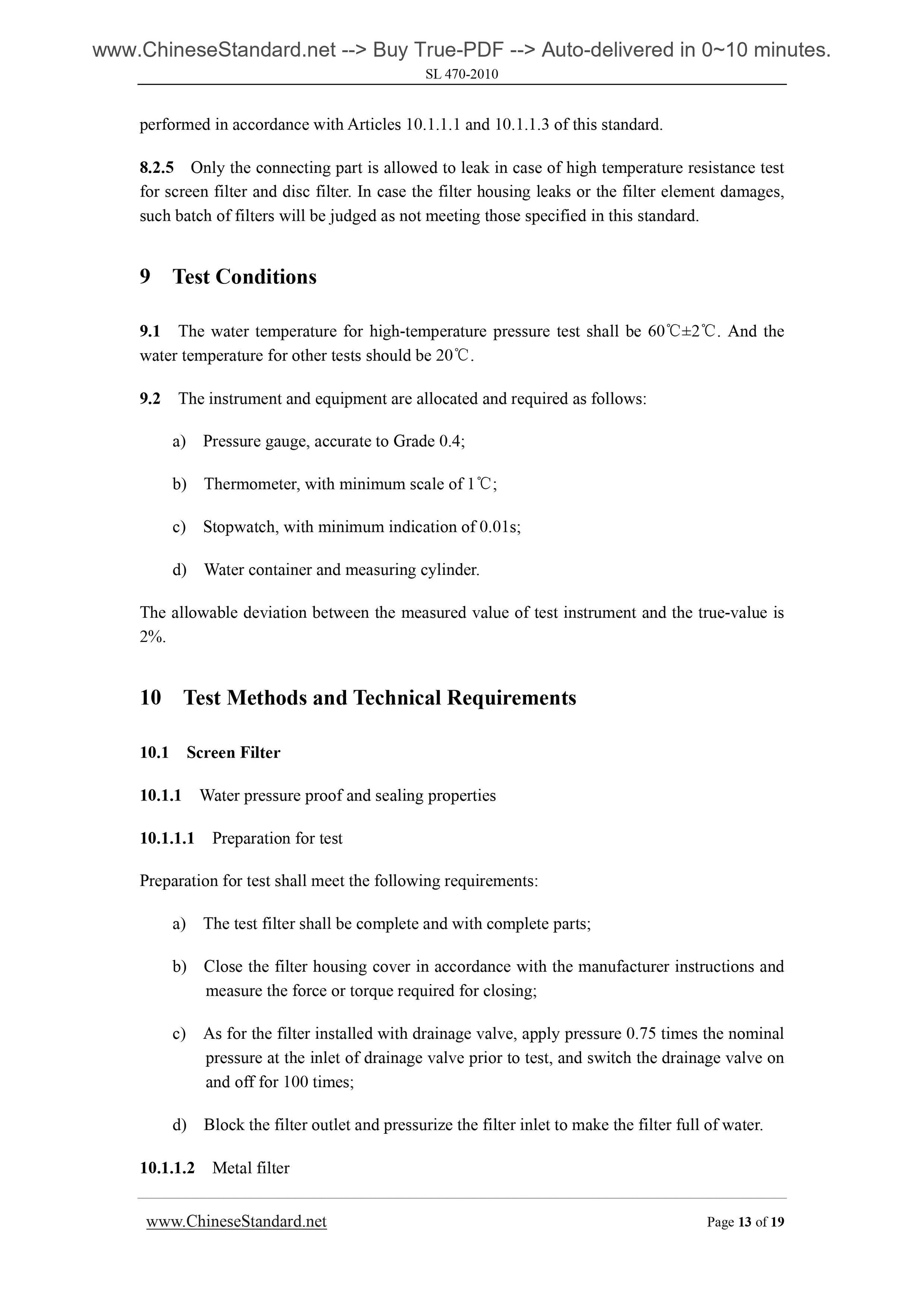

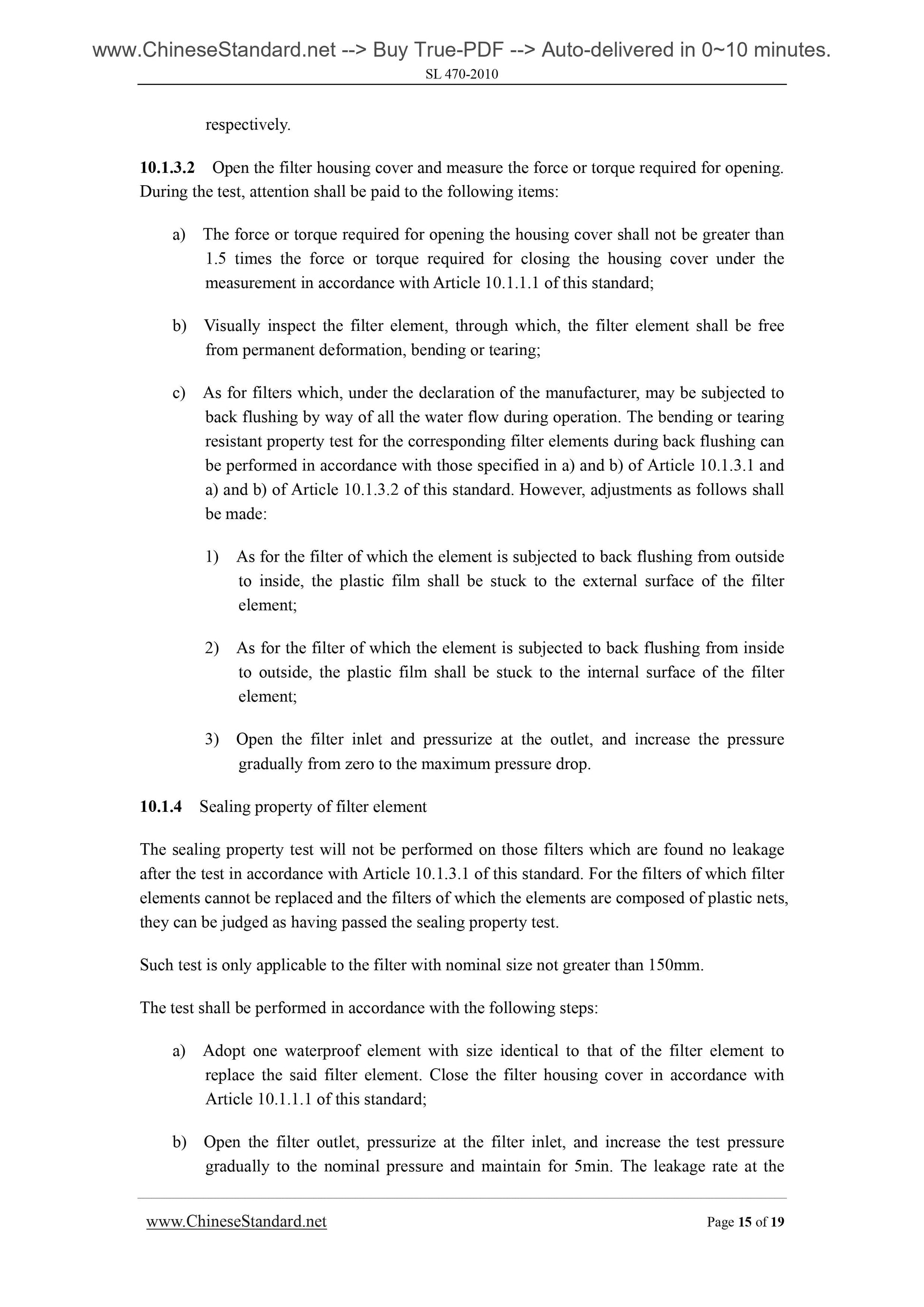

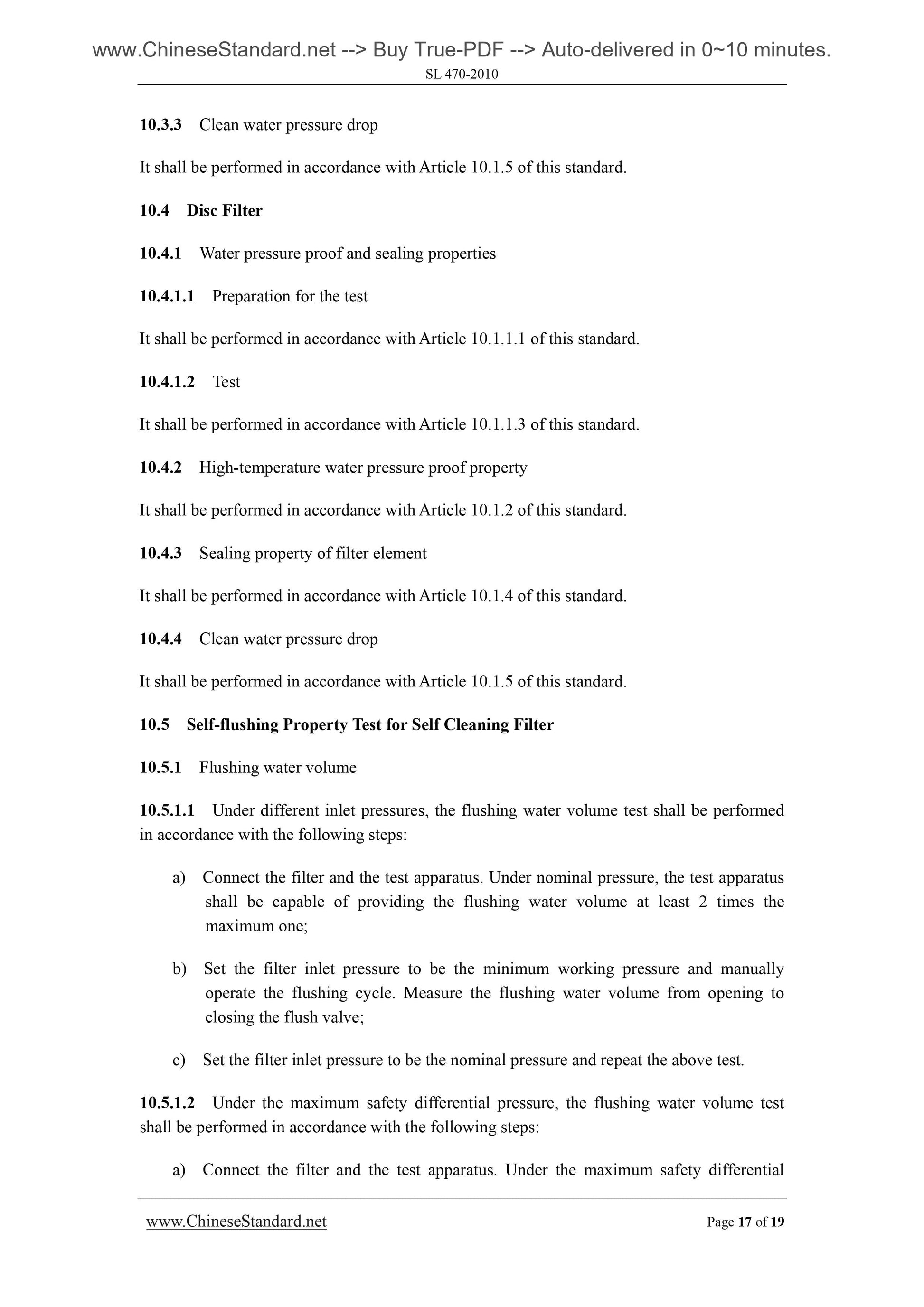

SL 470-2010: Basic parameters and technical requirements for irrigation filters

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click SL 470-2010 (Self-service in 1-minute)

Newer / historical versions: SL 470-2010

Preview True-PDF

Scope

This standard specifies basic parameters and technical requirements for screen filters,centrifugal filters (hydro-cyclone sand separators), sand media filters and disc filters.

Basic Data

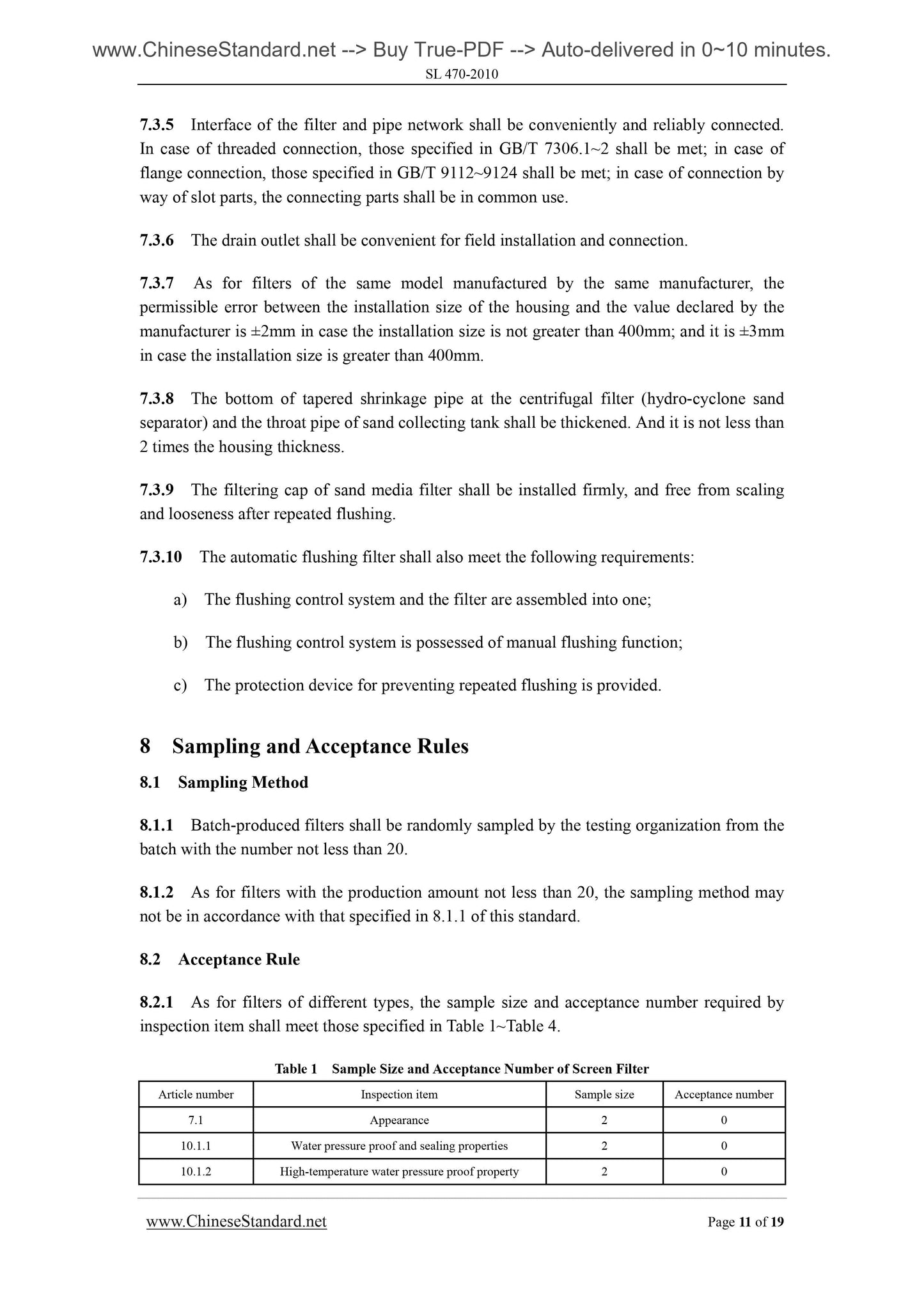

| Standard ID | SL 470-2010 (SL470-2010) |

| Description (Translated English) | Basic parameters and technical requirements for irrigation filters |

| Sector / Industry | Water Resources Industry Standard |

| Classification of Chinese Standard | B91 |

| Classification of International Standard | 65.060.35 |

| Word Count Estimation | 14,185 |

| Date of Issue | 2010-02-02 |

| Date of Implementation | 2010-05-02 |

| Quoted Standard | GB 150; GB/T 2828; GB/T 7306.1; GB/T 7306.2; GB/T 9112; GB/T 9113; GB/T 9114; GB/T 9115; GB/T 9116; GB/T 9117; GB/T 9118; GB/T 9119; GB/T 9120; GB/T 9121; GB/T 9122; GB/T 9123; GB/T 9124; GB/T 18690.2; GB/T 18690.3; JB/T 2932 |

| Regulation (derived from) | ?Ministry of Water Resources - Announcement 2010 No.6 |

| Issuing agency(ies) | Ministry of Water Resources of the People's Republic of China |

| Summary | This standard specifies the irrigation strainer, centrifugal filter (spin- sand water separator), gravel filter, basic parameters and technical conditions of laminated filter. |

Share