1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QC/T 626-2019 English PDF (QC/T626-2019)

QC/T 626-2019 English PDF (QC/T626-2019)

Regular price

$325.00

Regular price

Sale price

$325.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

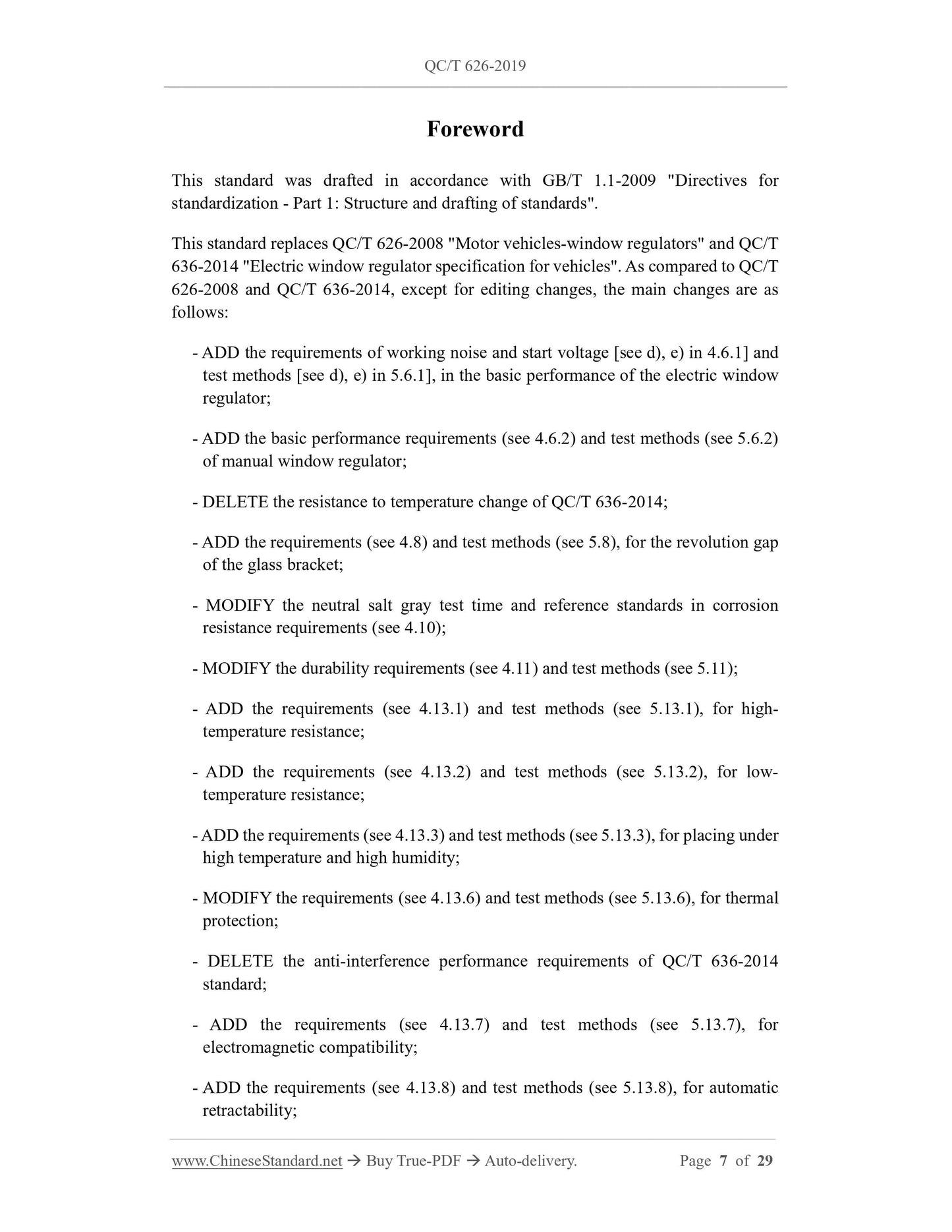

QC/T 626-2019: Motor vehicles - Window regulator

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click QC/T 626-2019 (Self-service in 1-minute)

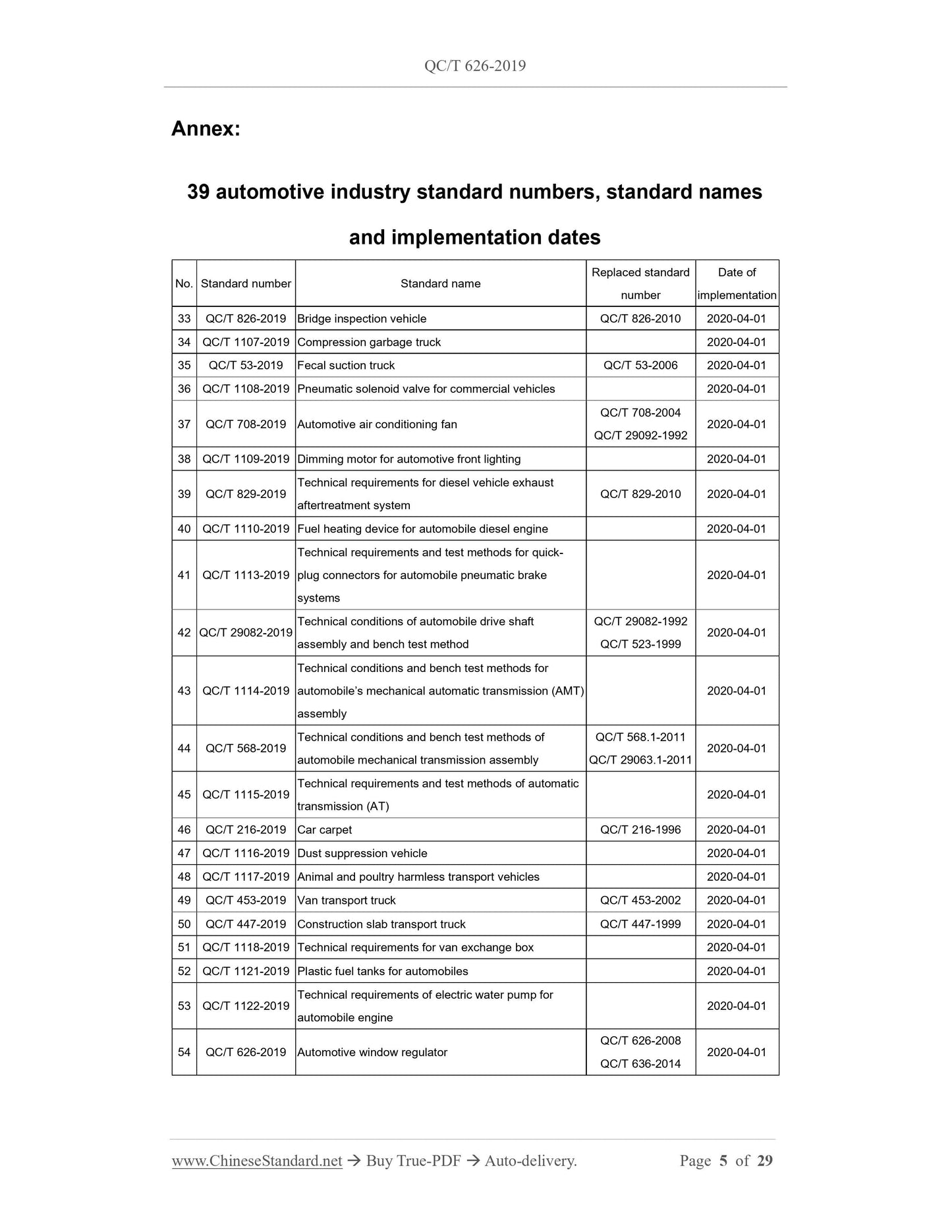

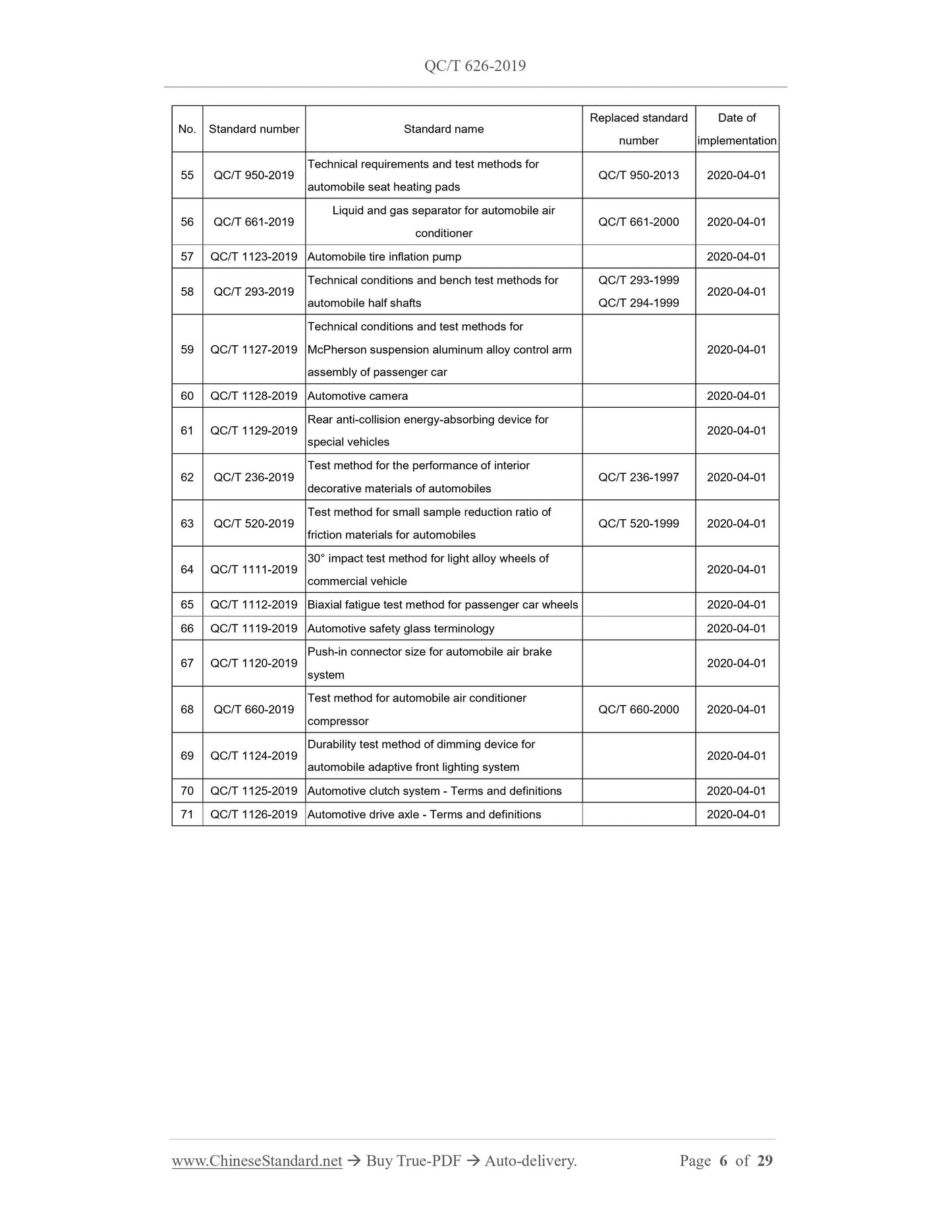

Newer / historical versions: QC/T 626-2019

Preview True-PDF

Scope

This standard specifies the terms and definitions, requirements, test methods, inspectionrules, signs, packaging, transportation, storage of window regulator for motor vehicles.

This standard applies to the manual window regulator AND electric window regulator,

which has a nominal voltage of 12 V and 24 V, as used on motor vehicles. Its structure

form relates to a rope type window regulator and a gear arm window regulator. The

window regulator, in other structural forms, may refer to this standard for

implementation.

Basic Data

| Standard ID | QC/T 626-2019 (QC/T626-2019) |

| Description (Translated English) | Motor vehicles - Window regulator |

| Sector / Industry | Automobile and Vehicle Industry Standard (Recommended) |

| Classification of Chinese Standard | T26 |

| Classification of International Standard | 43.040.60 |

| Word Count Estimation | 22,236 |

| Date of Issue | 2019 |

| Date of Implementation | 2020-04-01 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the terms and definitions, requirements, test methods, inspection rules, marking, packaging, transportation and storage of automotive glass regulators. This standard applies to manual glass lifts and electric glass lifts with nominal voltages of 12V and 24V used in automobiles. Can refer to the implementation. |

Share