1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QC/T 568-2019 English PDF (QC/T568-2019)

QC/T 568-2019 English PDF (QC/T568-2019)

Regular price

$265.00

Regular price

Sale price

$265.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

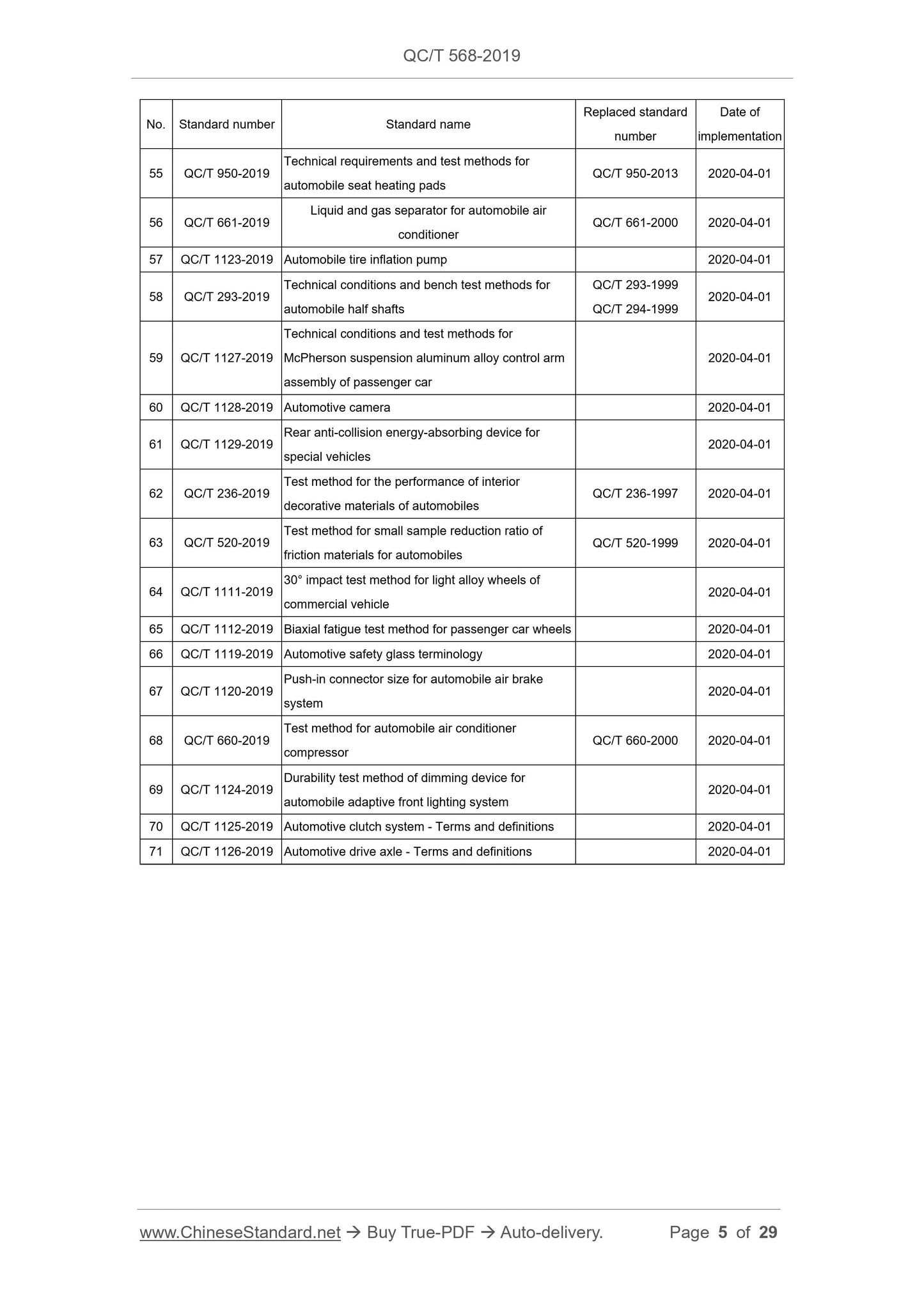

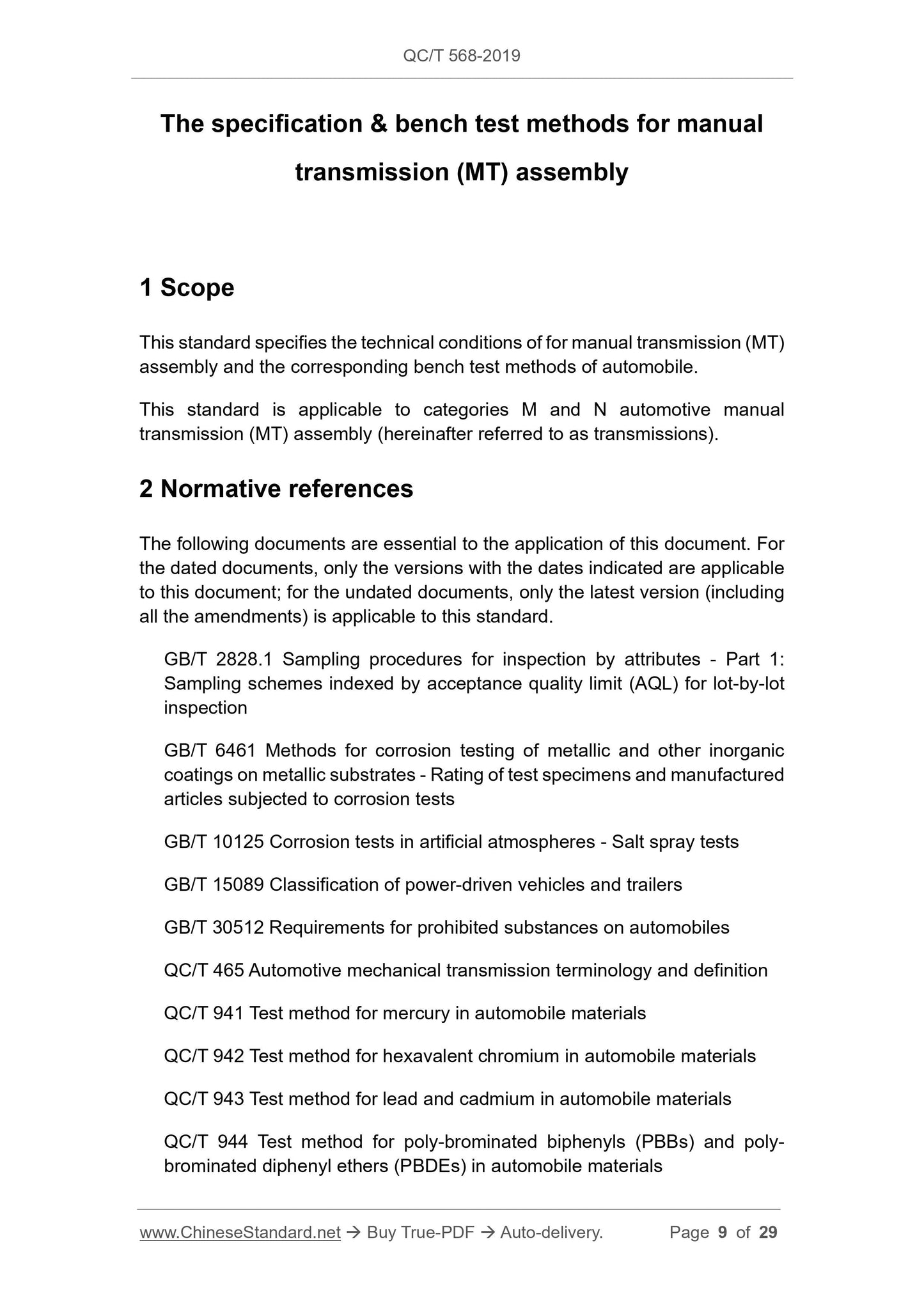

QC/T 568-2019: The specification and bench test methods for manual transmission (MT) assembly

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click QC/T 568-2019 (Self-service in 1-minute)

Newer / historical versions: QC/T 568-2019

Preview True-PDF

Scope

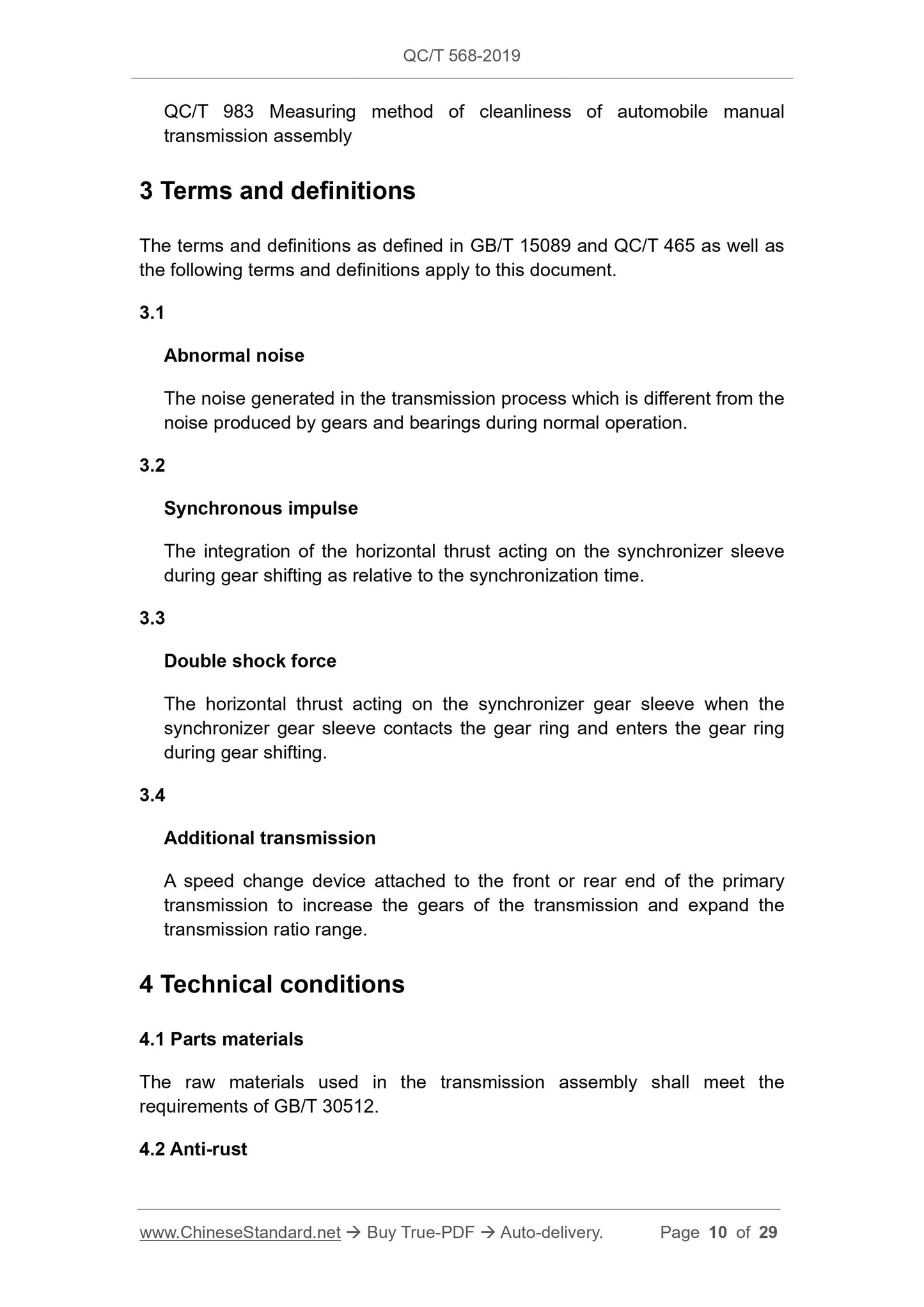

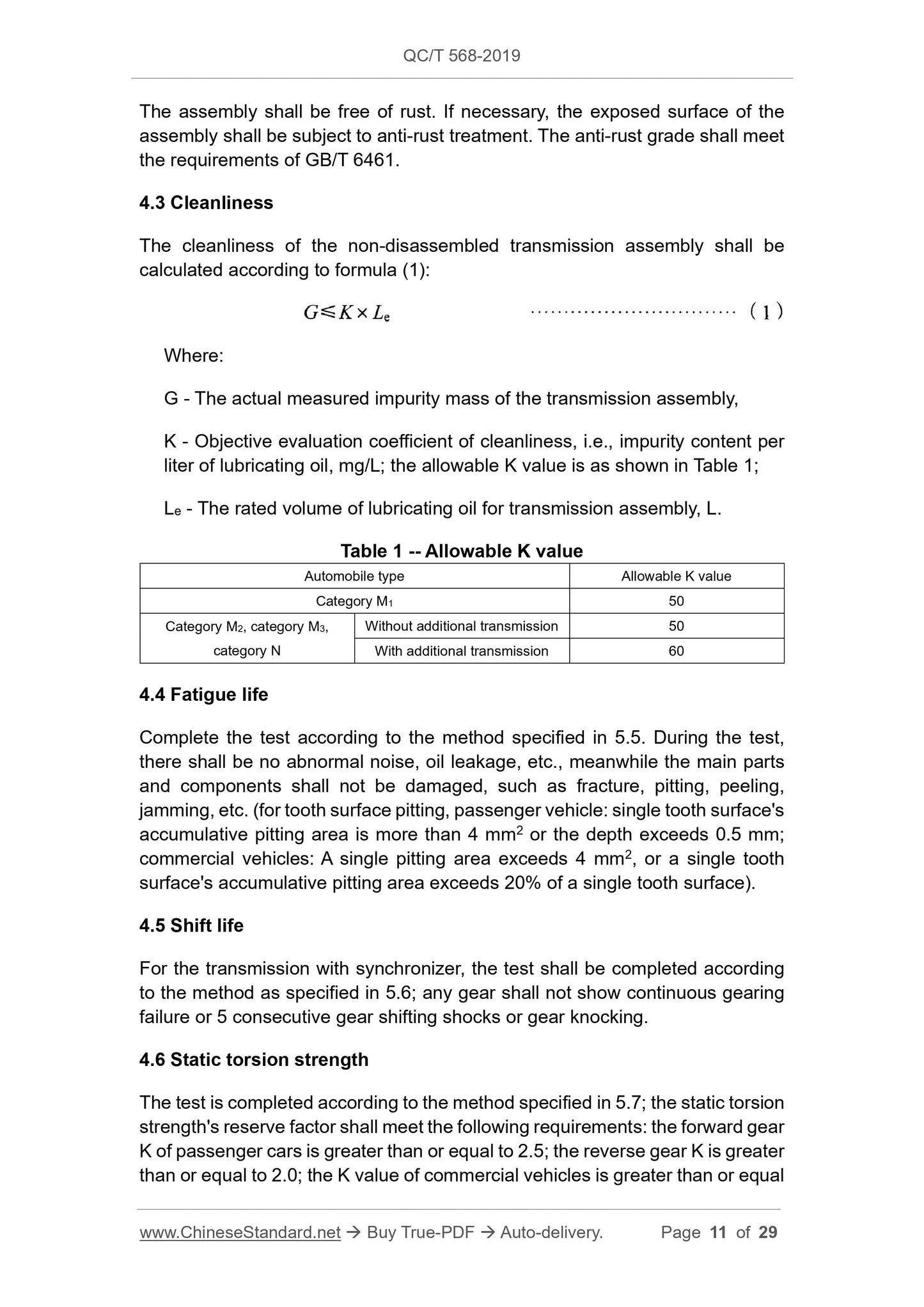

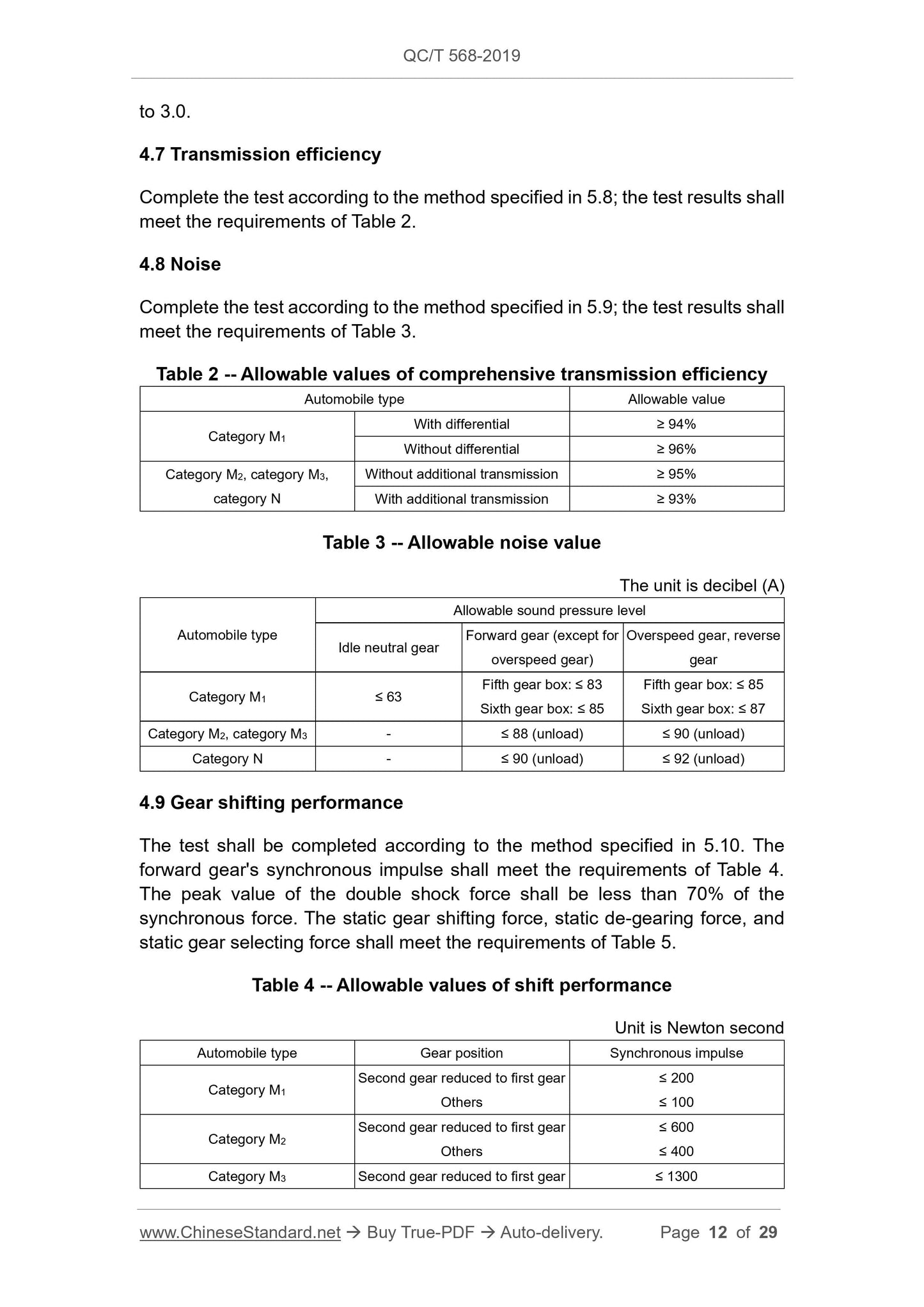

This standard specifies the technical conditions of for manual transmission (MT)assembly and the corresponding bench test methods of automobile.

This standard is applicable to categories M and N automotive manual

transmission (MT) assembly (hereinafter referred to as transmissions).

Basic Data

| Standard ID | QC/T 568-2019 (QC/T568-2019) |

| Description (Translated English) | The specification and bench test methods for manual transmission (MT) assembly |

| Sector / Industry | Automobile and Vehicle Industry Standard (Recommended) |

| Classification of Chinese Standard | T21 |

| Classification of International Standard | 43.040.50 |

| Word Count Estimation | 21,233 |

| Date of Issue | 2019 |

| Date of Implementation | 2020-04-01 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the technical conditions and corresponding bench test methods for automotive mechanical transmission assemblies. This standard applies to M-type, N-type automotive mechanical transmission assembly. |

Share