1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QC/T 236-2019 English PDF (QC/T236-2019)

QC/T 236-2019 English PDF (QC/T236-2019)

Regular price

$410.00

Regular price

Sale price

$410.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

QC/T 236-2019: Test method for automotive interior decorative material properties

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click QC/T 236-2019 (Self-service in 1-minute)

Newer / historical versions: QC/T 236-2019

Preview True-PDF

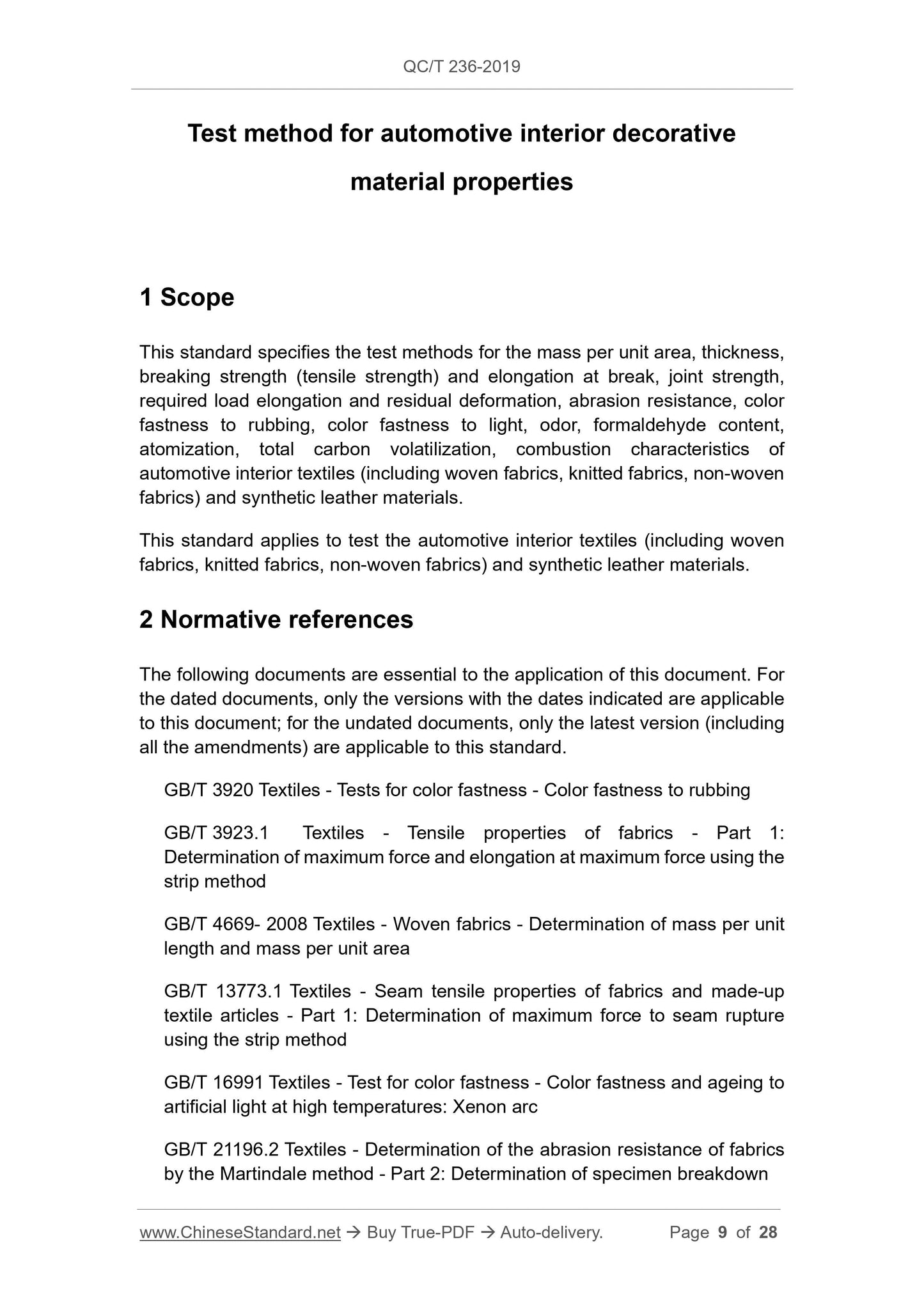

Scope

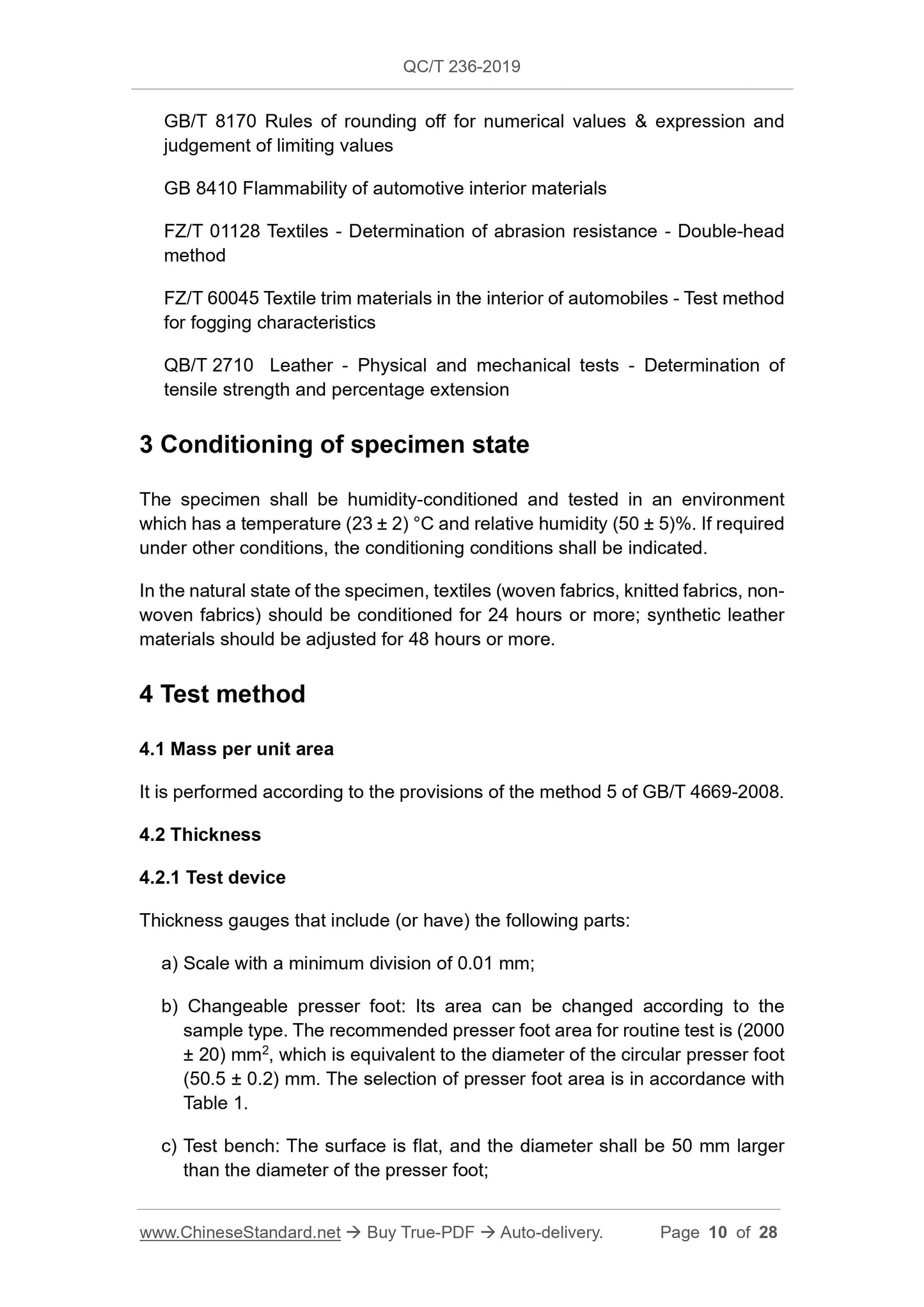

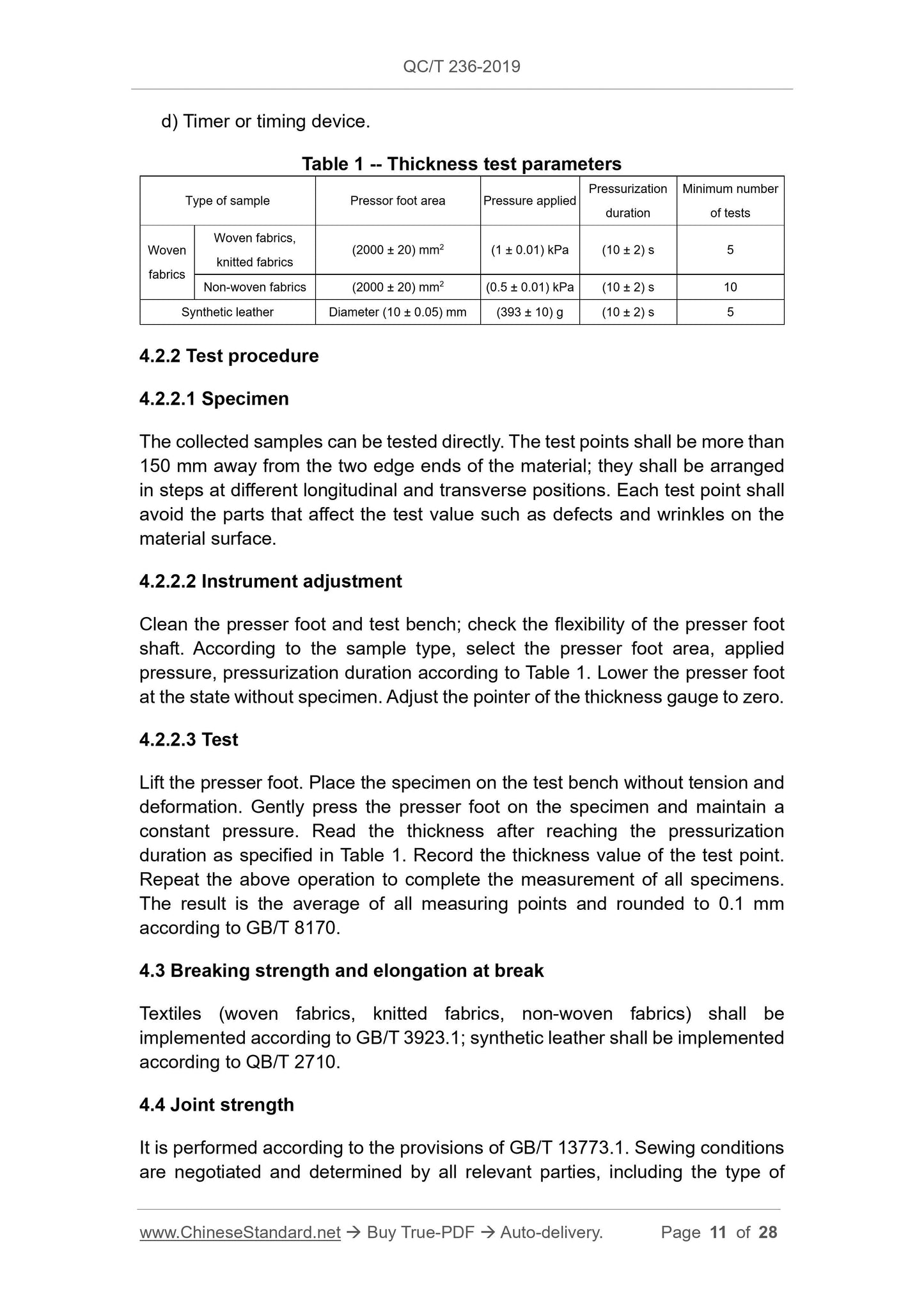

This standard specifies the test methods for the mass per unit area, thickness,breaking strength (tensile strength) and elongation at break, joint strength,

required load elongation and residual deformation, abrasion resistance, color

fastness to rubbing, color fastness to light, odor, formaldehyde content,

atomization, total carbon volatilization, combustion characteristics of

automotive interior textiles (including woven fabrics, knitted fabrics, non-woven

fabrics) and synthetic leather materials.

This standard applies to test the automotive interior textiles (including woven

fabrics, knitted fabrics, non-woven fabrics) and synthetic leather materials.

Basic Data

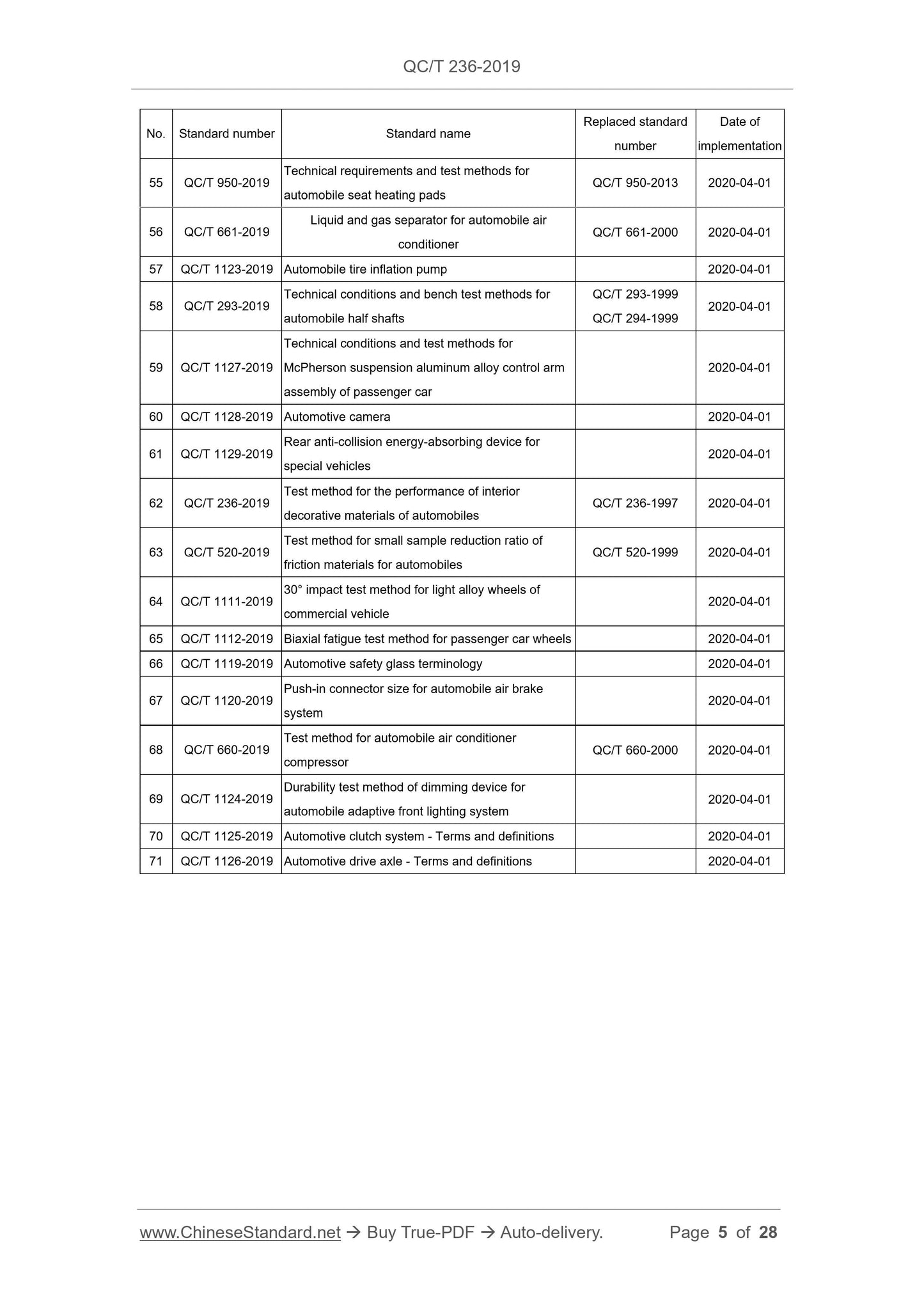

| Standard ID | QC/T 236-2019 (QC/T236-2019) |

| Description (Translated English) | Test method for automotive interior decorative material properties |

| Sector / Industry | Automobile and Vehicle Industry Standard (Recommended) |

| Classification of Chinese Standard | T20 |

| Classification of International Standard | 43.040.60 |

| Word Count Estimation | 21,221 |

| Date of Issue | 2019 |

| Date of Implementation | 2020-04-01 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the mass per unit area, thickness, breaking strength (tensile strength) and elongation at break, seam strength, constant load of automotive interior textiles (including woven fabrics, knitted fabrics, non-woven fabrics) and synthetic leather materials Test methods for elongation and residual deformation, abrasion resistance, color fastness to rubbing, color fastness to light, odor, formaldehyde content, atomization, total carbon volatilization, combustion characteristics. This standard applies to testing automotive interior textiles (including woven fabrics, knitted fabrics, non-woven fabrics) and synthetic leather materials. |

Share