1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QC/T 1112-2019 English PDF (QC/T1112-2019)

QC/T 1112-2019 English PDF (QC/T1112-2019)

Regular price

$235.00

Regular price

Sale price

$235.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

QC/T 1112-2019: Passenger cars-biaxial fatigue test method for wheels

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click QC/T 1112-2019 (Self-service in 1-minute)

Newer / historical versions: QC/T 1112-2019

Preview True-PDF

Scope

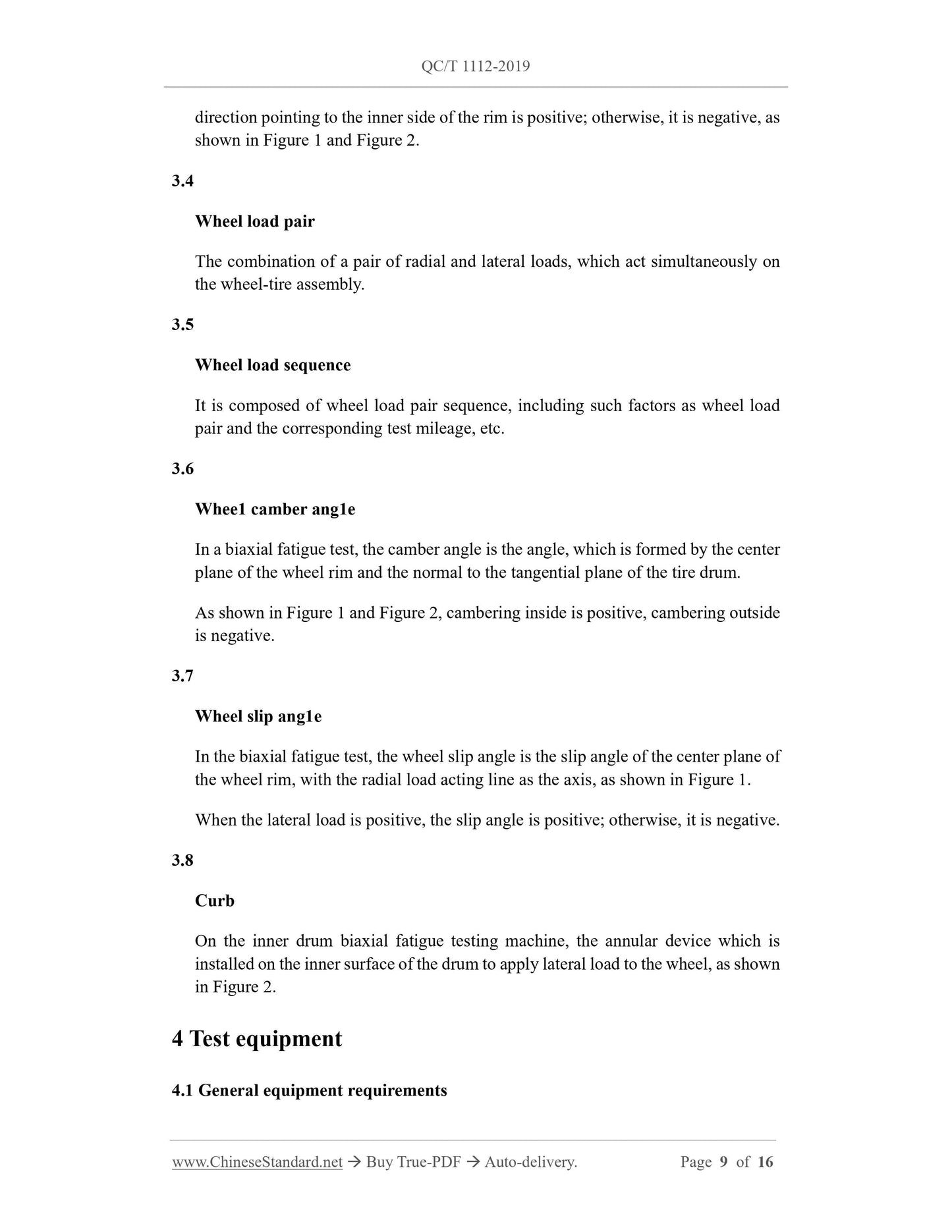

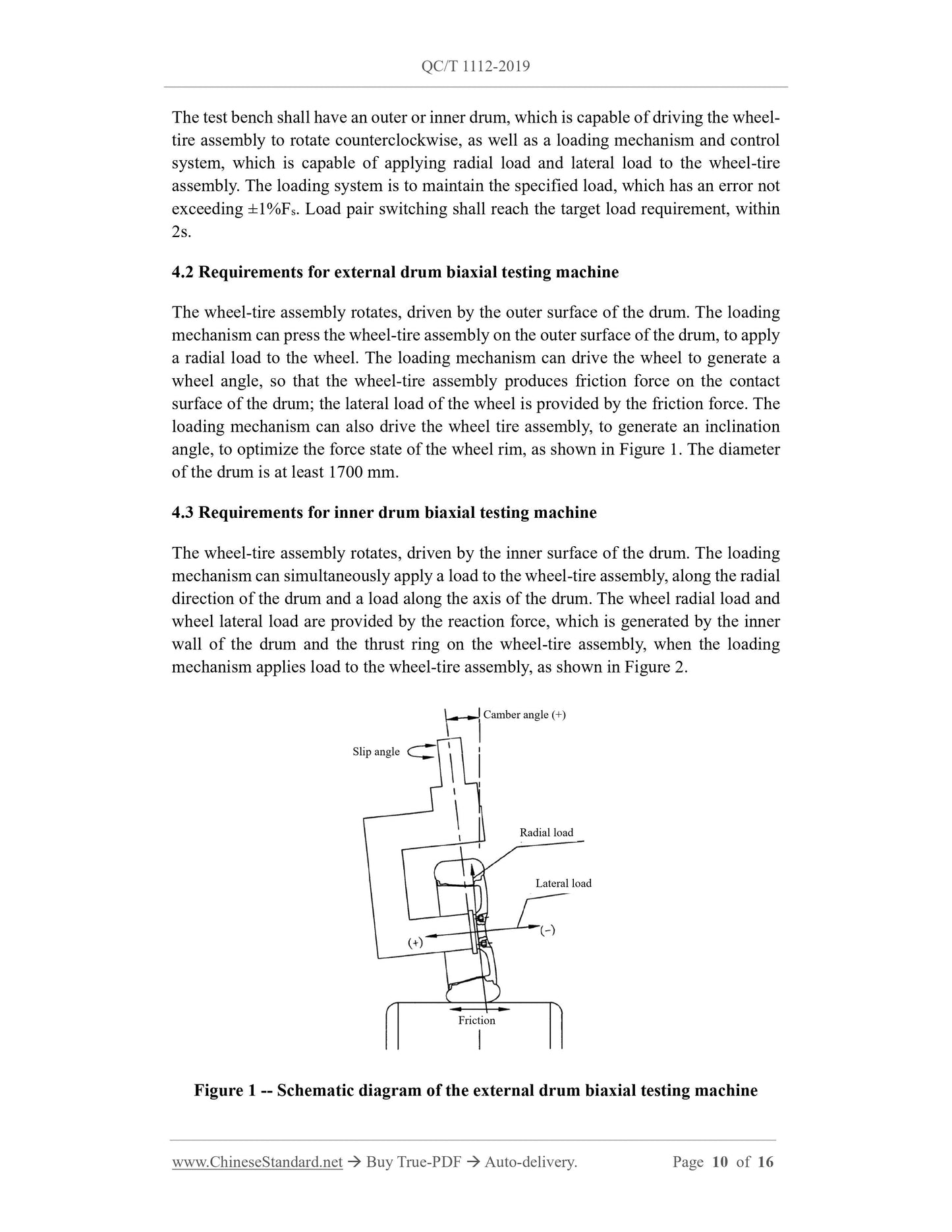

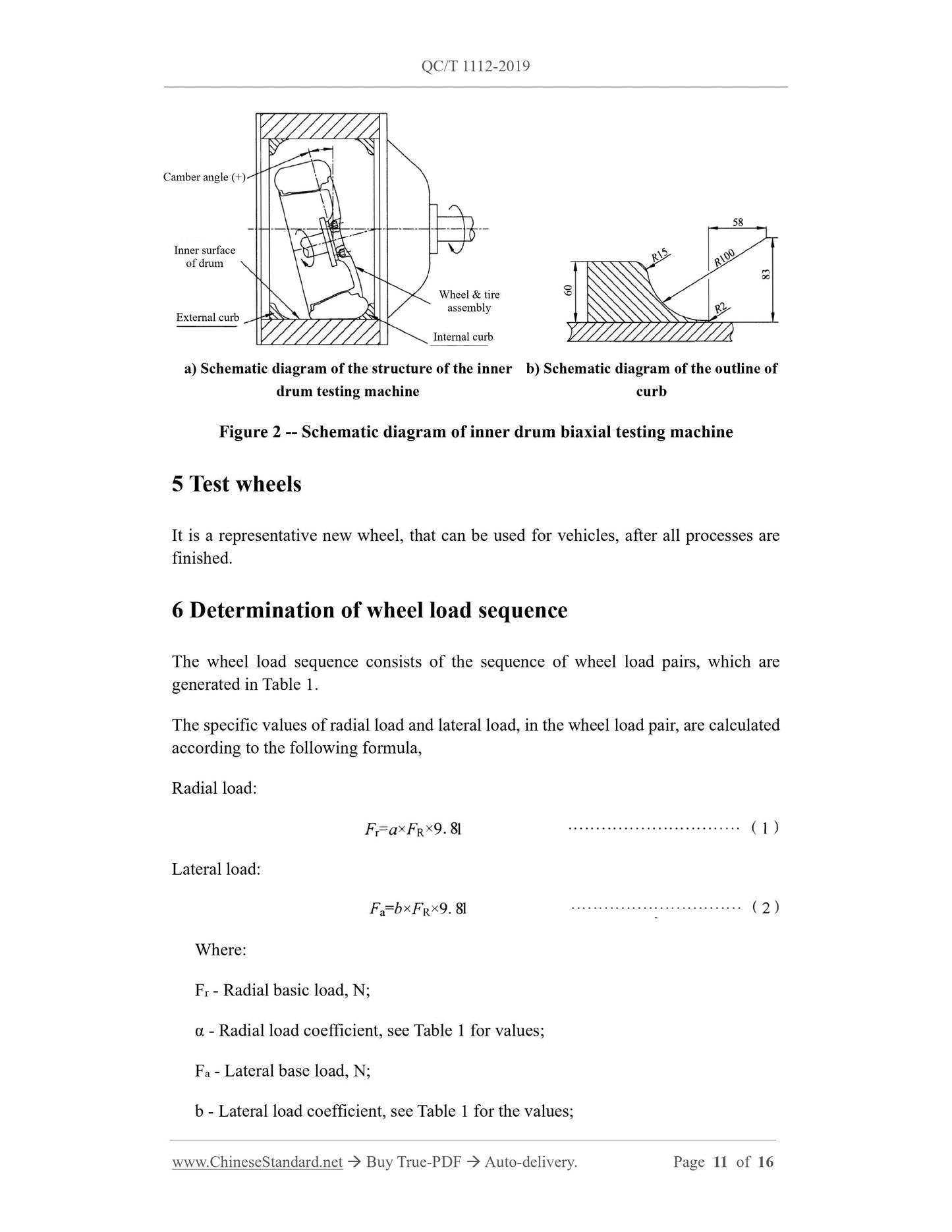

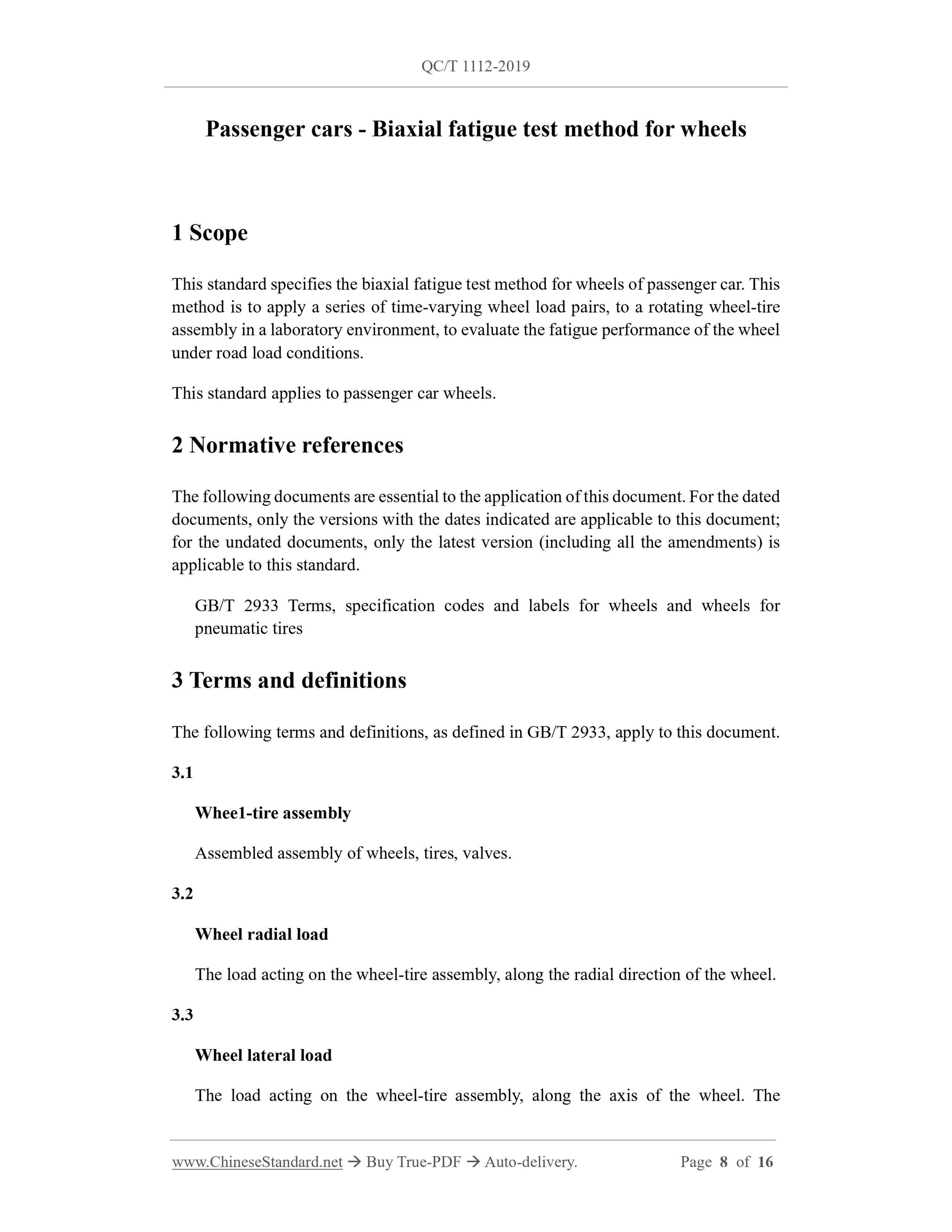

This standard specifies the biaxial fatigue test method for wheels of passenger car. Thismethod is to apply a series of time-varying wheel load pairs, to a rotating wheel-tire

assembly in a laboratory environment, to evaluate the fatigue performance of the wheel

under road load conditions.

This standard applies to passenger car wheels.

Basic Data

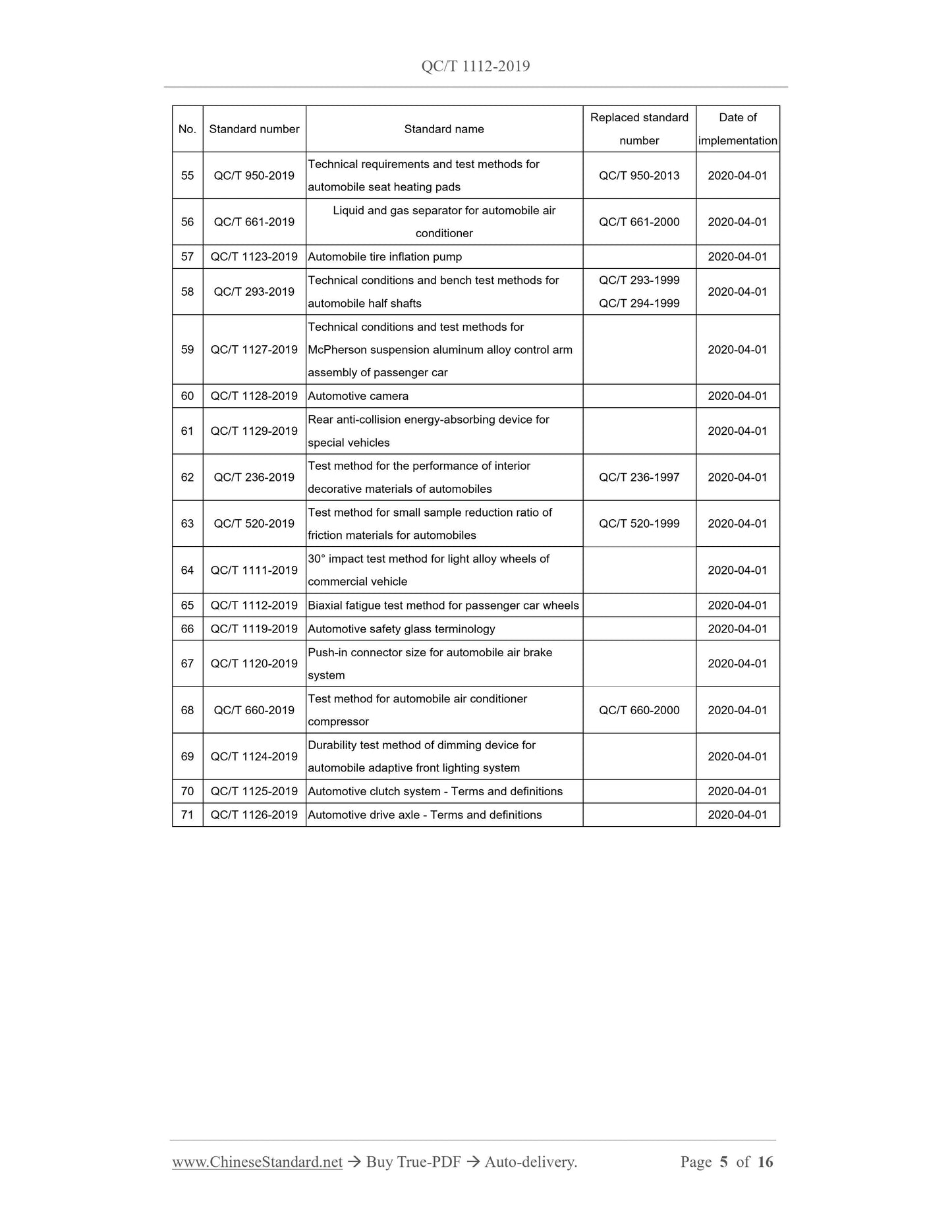

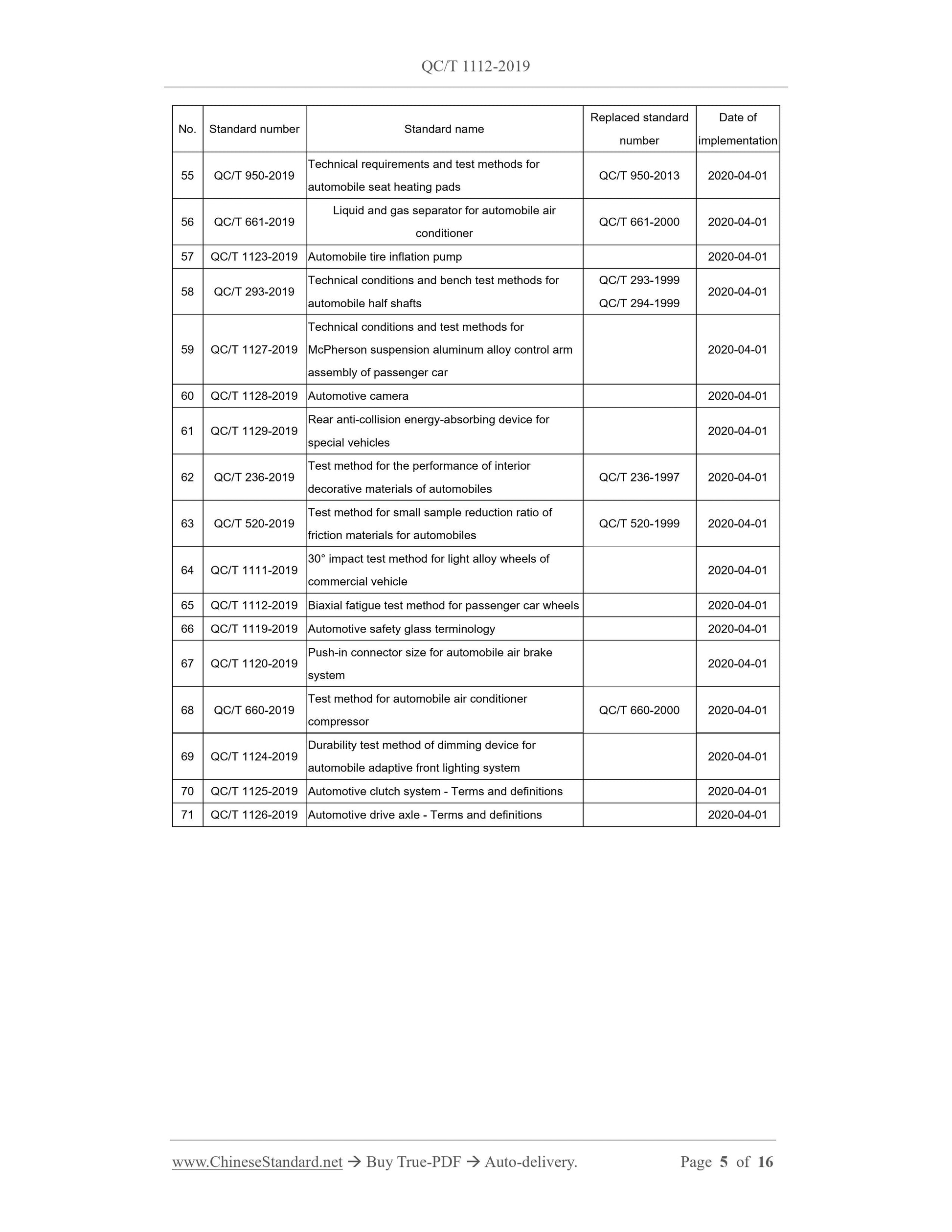

| Standard ID | QC/T 1112-2019 (QC/T1112-2019) |

| Description (Translated English) | Passenger cars-biaxial fatigue test method for wheels |

| Sector / Industry | Automobile and Vehicle Industry Standard (Recommended) |

| Classification of Chinese Standard | T22 |

| Classification of International Standard | 43.040.50 |

| Word Count Estimation | 14,148 |

| Date of Issue | 2019 |

| Date of Implementation | 2020-04-01 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the biaxial fatigue test method for passenger car wheels. The method is to apply a series of time-varying wheel load pairs to a rotating wheel and tire assembly in a laboratory environment to assess the fatigue performance of the wheel under road load conditions. This standard applies to passenger car wheels. |

Share