1

/

of

11

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QC/T 1111-2019 English PDF (QC/T1111-2019)

QC/T 1111-2019 English PDF (QC/T1111-2019)

Regular price

$190.00

Regular price

Sale price

$190.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

QC/T 1111-2019: Commercial vehicles - Light alloy wheels - 30-degree impact test method

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click QC/T 1111-2019 (Self-service in 1-minute)

Newer / historical versions: QC/T 1111-2019

Preview True-PDF

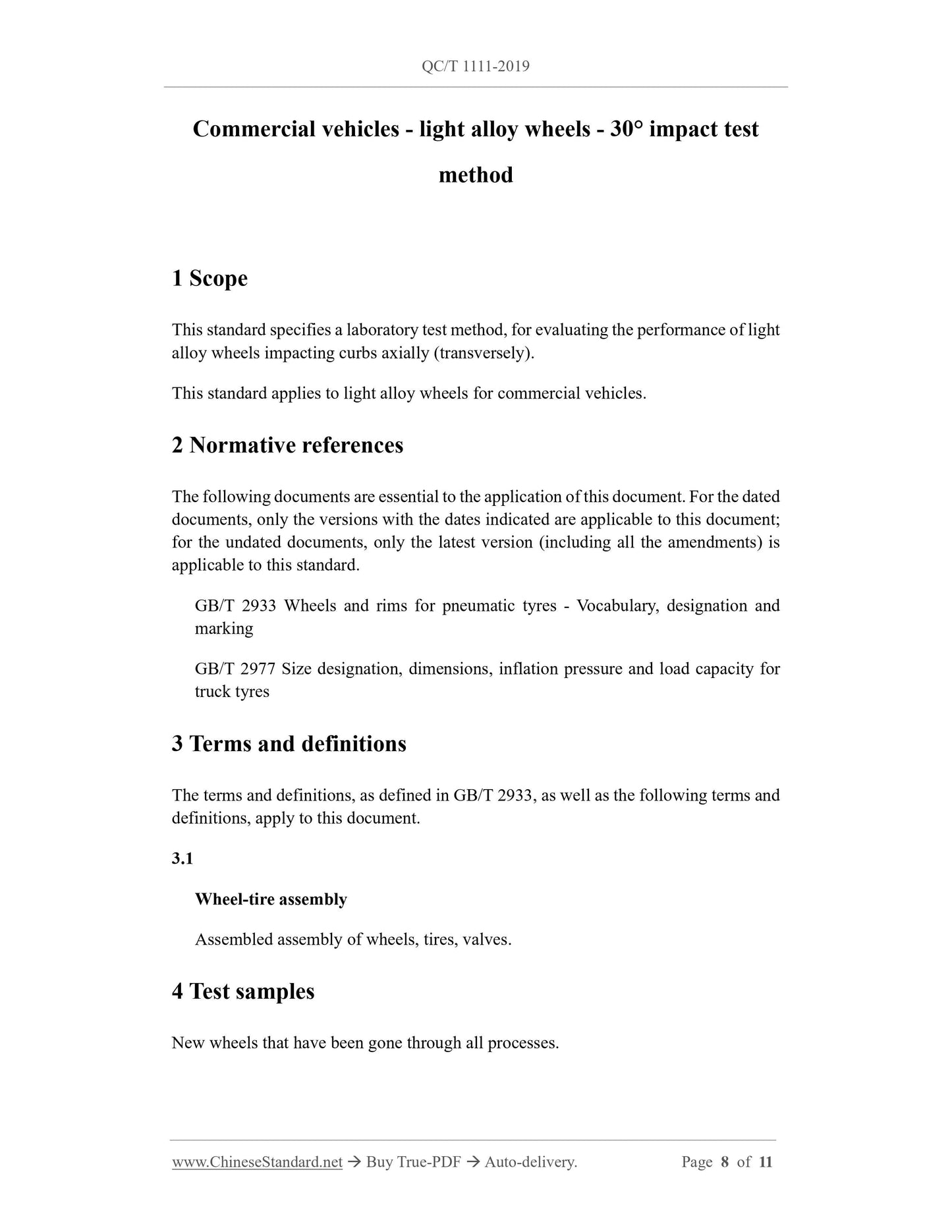

Scope

This standard specifies a laboratory test method, for evaluating the performance of lightalloy wheels impacting curbs axially (transversely).

This standard applies to light alloy wheels for commercial vehicles.

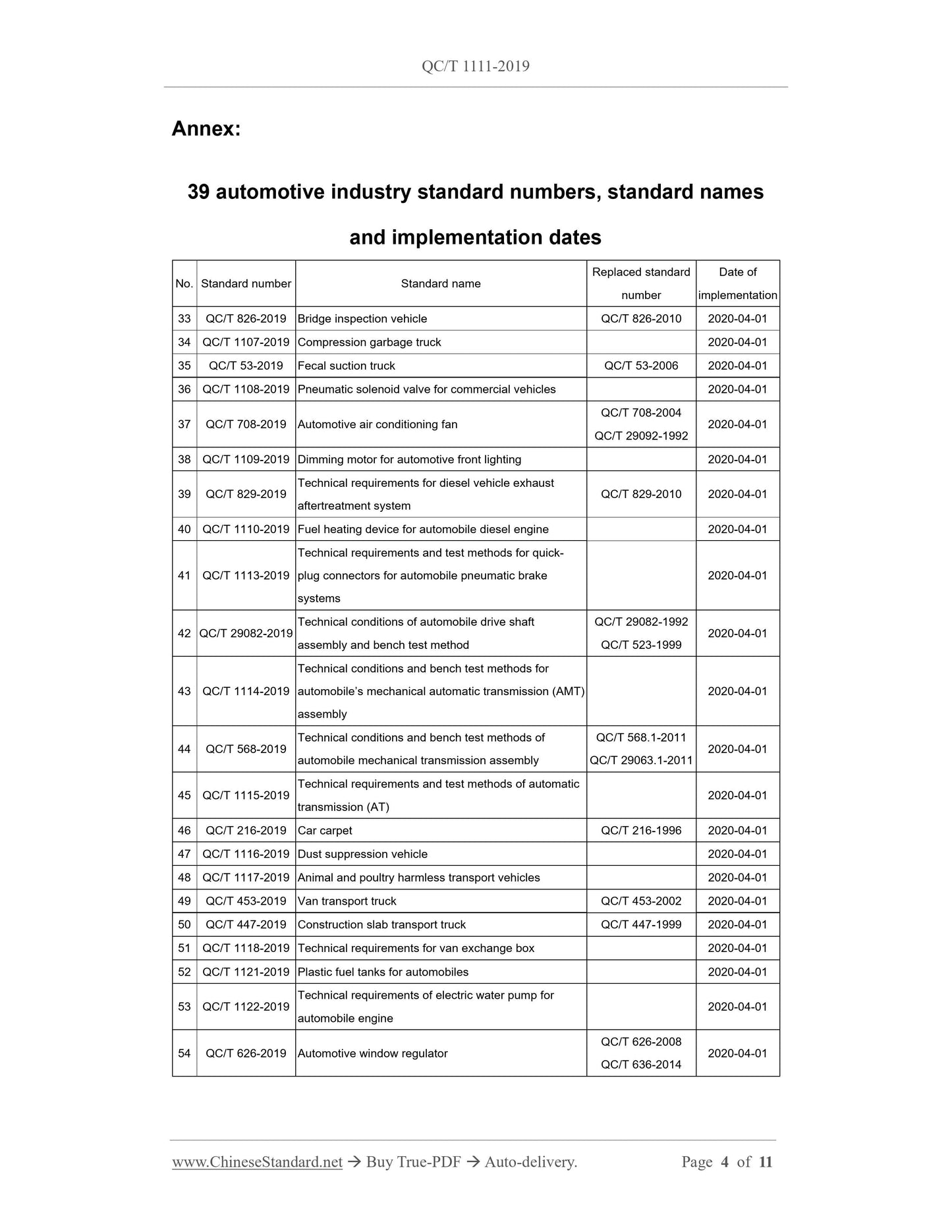

Basic Data

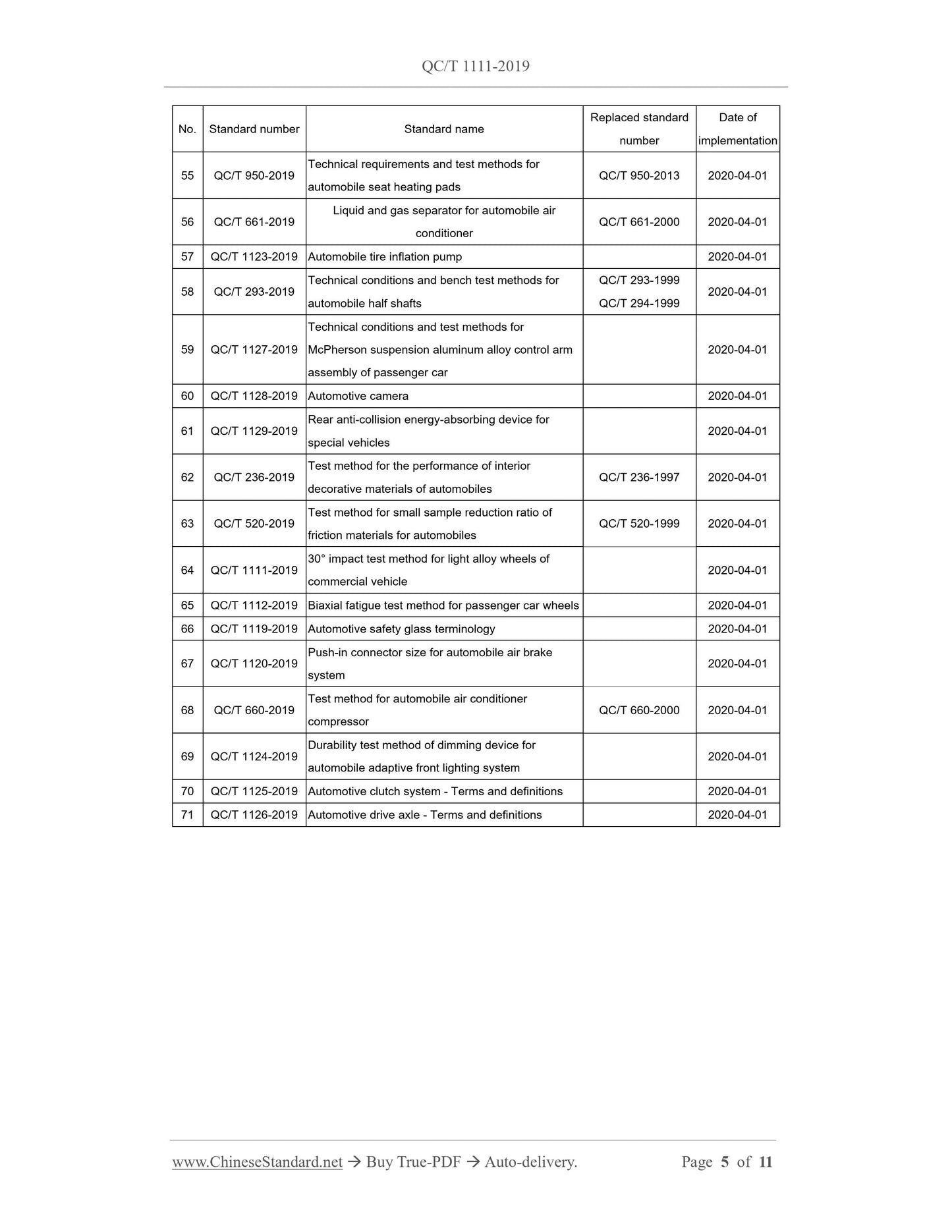

| Standard ID | QC/T 1111-2019 (QC/T1111-2019) |

| Description (Translated English) | Commercial vehicles - Light alloy wheels - 30-degree impact test method |

| Sector / Industry | Automobile and Vehicle Industry Standard (Recommended) |

| Classification of Chinese Standard | T22 |

| Classification of International Standard | 43.040.50 |

| Word Count Estimation | 12,190 |

| Date of Issue | 2019 |

| Date of Implementation | 2020-04-01 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies a laboratory test method for evaluating the performance of light alloy wheels in axial (lateral) impact on curbs. This standard applies to light alloy wheels of commercial vehicles. |

Share