1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QC/T 1026-2016 English PDF (QC/T1026-2016)

QC/T 1026-2016 English PDF (QC/T1026-2016)

Regular price

$140.00

Regular price

Sale price

$140.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

QC/T 1026-2016: Performance and determination of PVC slush skin of automotive instrument panel

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click QC/T 1026-2016 (Self-service in 1-minute)

Newer / historical versions: QC/T 1026-2016

Preview True-PDF

Scope

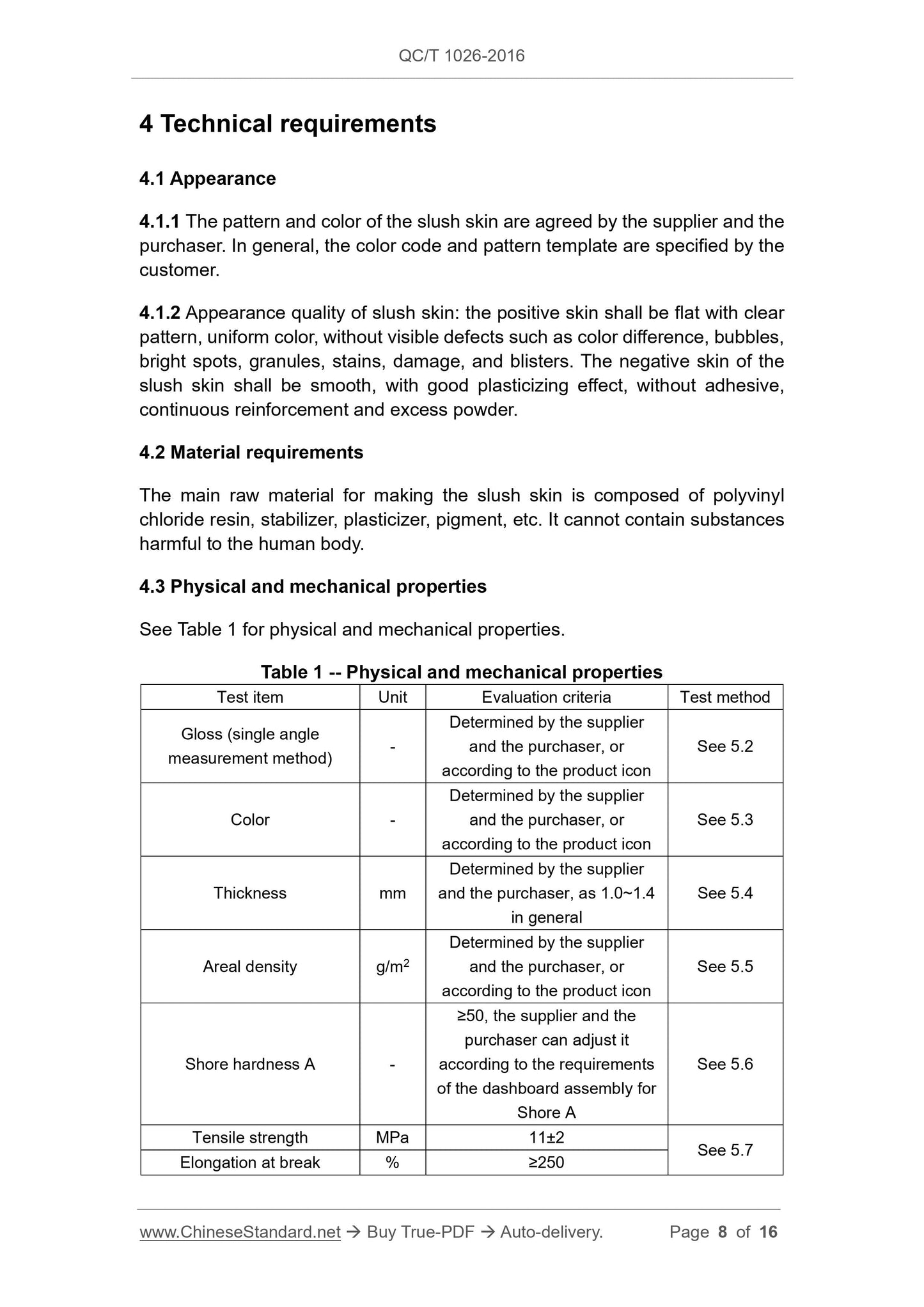

This Standard specifies technical requirements and test methods for PVC slushskin of automotive instrument panel.

This Standard is applicable to PVC slush skin of automotive instrument panel

mainly made of polyvinyl chloride powder (hereinafter referred to as the slush

skin).

Basic Data

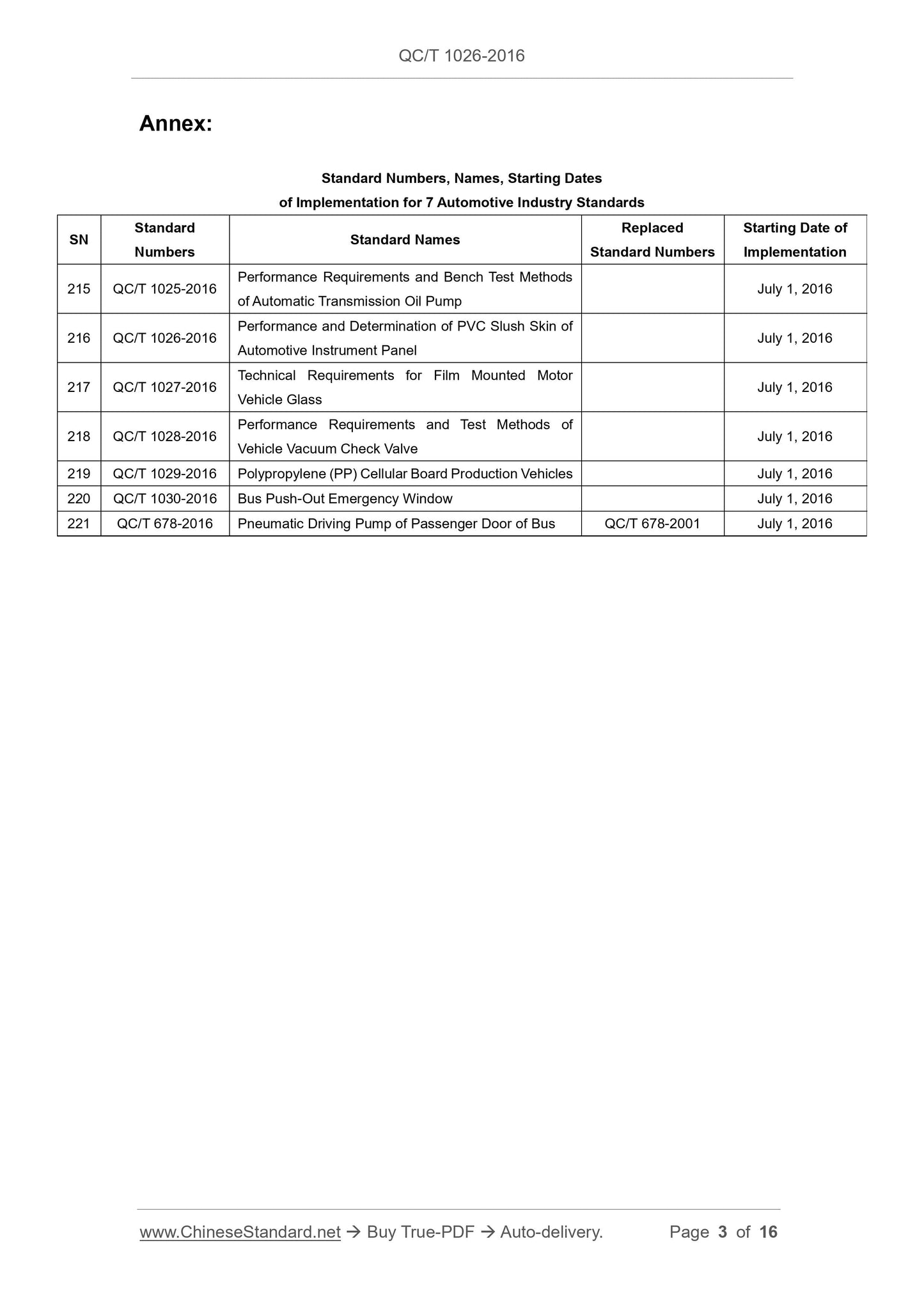

| Standard ID | QC/T 1026-2016 (QC/T1026-2016) |

| Description (Translated English) | Performance and determination of PVC slush skin of automotive instrument panel |

| Sector / Industry | Automobile and Vehicle Industry Standard (Recommended) |

| Classification of Chinese Standard | T20 |

| Classification of International Standard | 43.040.60 |

| Word Count Estimation | 11,111 |

| Date of Issue | 2016-01-15 |

| Date of Implementation | 2016-07-01 |

| Quoted Standard | GB/T 250-2008; GB/T 251-2008; GB/T 1040.1-2006; GB/T 1040.3-2006; GB/T 2411-2008; GB/T 2918-1998; GB/T 3920-2008; GB 8410; GB/T 9754-2007; GB/T 16422.1-2006; GB/T 16422.2-1999; ISO 105-B06-1998; ISO 105-B06 AMD 1-2002; ISO 6452-2000; ISO 6721-1-2011; ISO 6721-4-2012 |

| Regulation (derived from) | ?Ministry of Industry and Information Technology Bulletin 2016 No.3 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the technical requirements and test methods for the skin of slush dashboard for automobiles. This standard applies to polyvinyl chloride powder as the main raw material for automotive slush dashboard skin (hereinafter referred to as the skin). |

Share