1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QB/T 2957-2008 English PDF (QB/T2957-2008)

QB/T 2957-2008 English PDF (QB/T2957-2008)

Regular price

$155.00

Regular price

Sale price

$155.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

QB/T 2957-2008: Determination of starch content of starch based plastics Thermogravimetry(TG)

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click QB/T 2957-2008 (Self-service in 1-minute)

Newer / historical versions: QB/T 2957-2008

Preview True-PDF

Scope

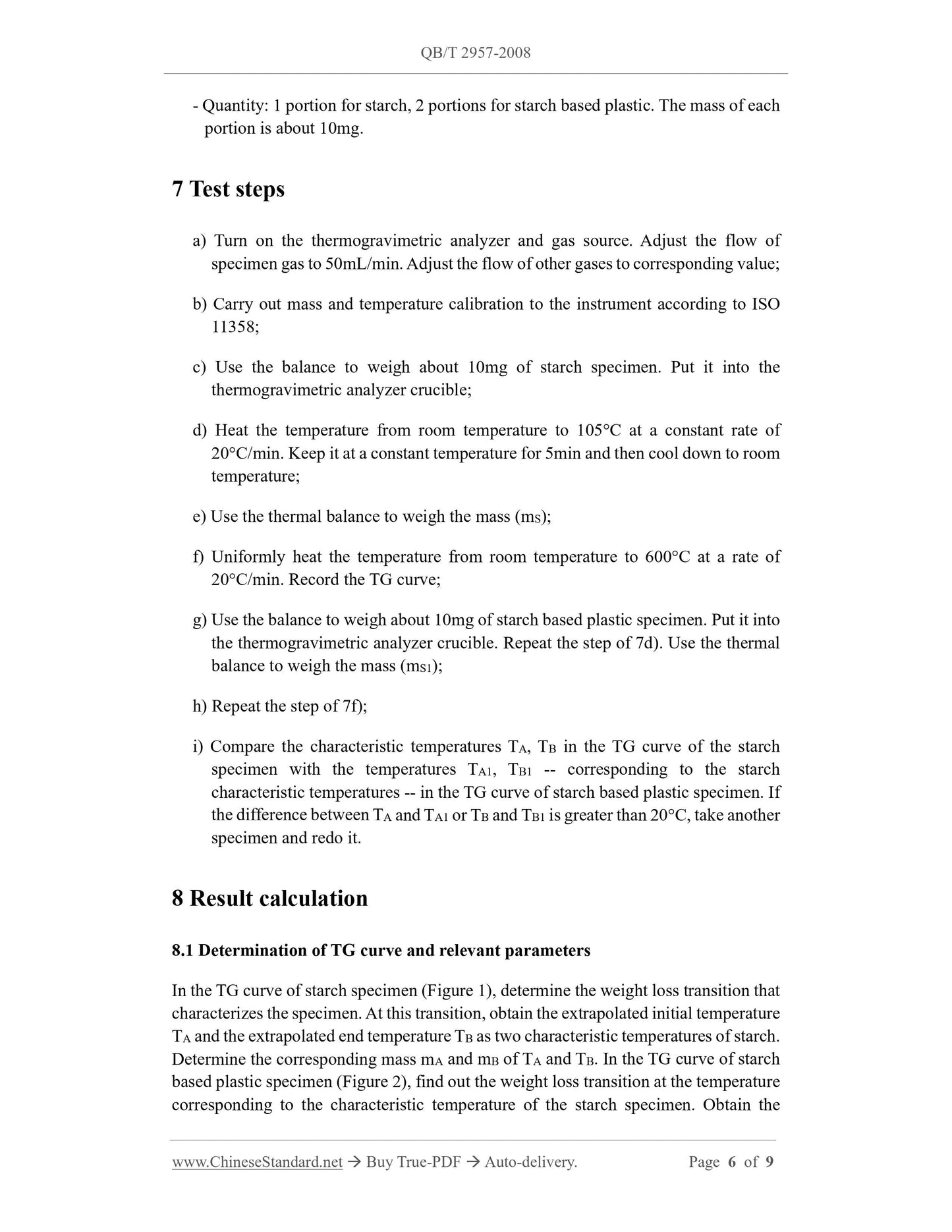

This Standard specifies the method to determine starch content in starch based plastics.This Standard is applicable to starch based plastics with starch and resin as the main

raw materials that have obvious differences in the characteristic temperature of thermal

weight loss.

Basic Data

| Standard ID | QB/T 2957-2008 (QB/T2957-2008) |

| Description (Translated English) | Determination of starch content of starch based plastics Thermogravimetry(TG) |

| Sector / Industry | Light Industry Standard (Recommended) |

| Classification of Chinese Standard | G32 |

| Classification of International Standard | 83.180 |

| Word Count Estimation | 6,628 |

| Date of Issue | 2008-03-12 |

| Date of Implementation | 2008-09-01 |

| Quoted Standard | GB/T 6425; ISO 11358 |

| Regulation (derived from) | ?Development and Reform Commission Announcement 2008 No.25 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the determination of starch-based plastics in starch content. This standard applies to a more significant difference in the weight loss characteristic temperature of the resin as the main raw starch and starch-based plastics. |

Share