1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QB/T 2881-2013 English PDF (QB/T2881-2013)

QB/T 2881-2013 English PDF (QB/T2881-2013)

Regular price

$200.00

Regular price

Sale price

$200.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

QB/T 2881-2013: Footwear and footwear components - Antimicrobial performance specifications

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click QB/T 2881-2013 (Self-service in 1-minute)

Newer / historical versions: QB/T 2881-2013

Preview True-PDF

Scope

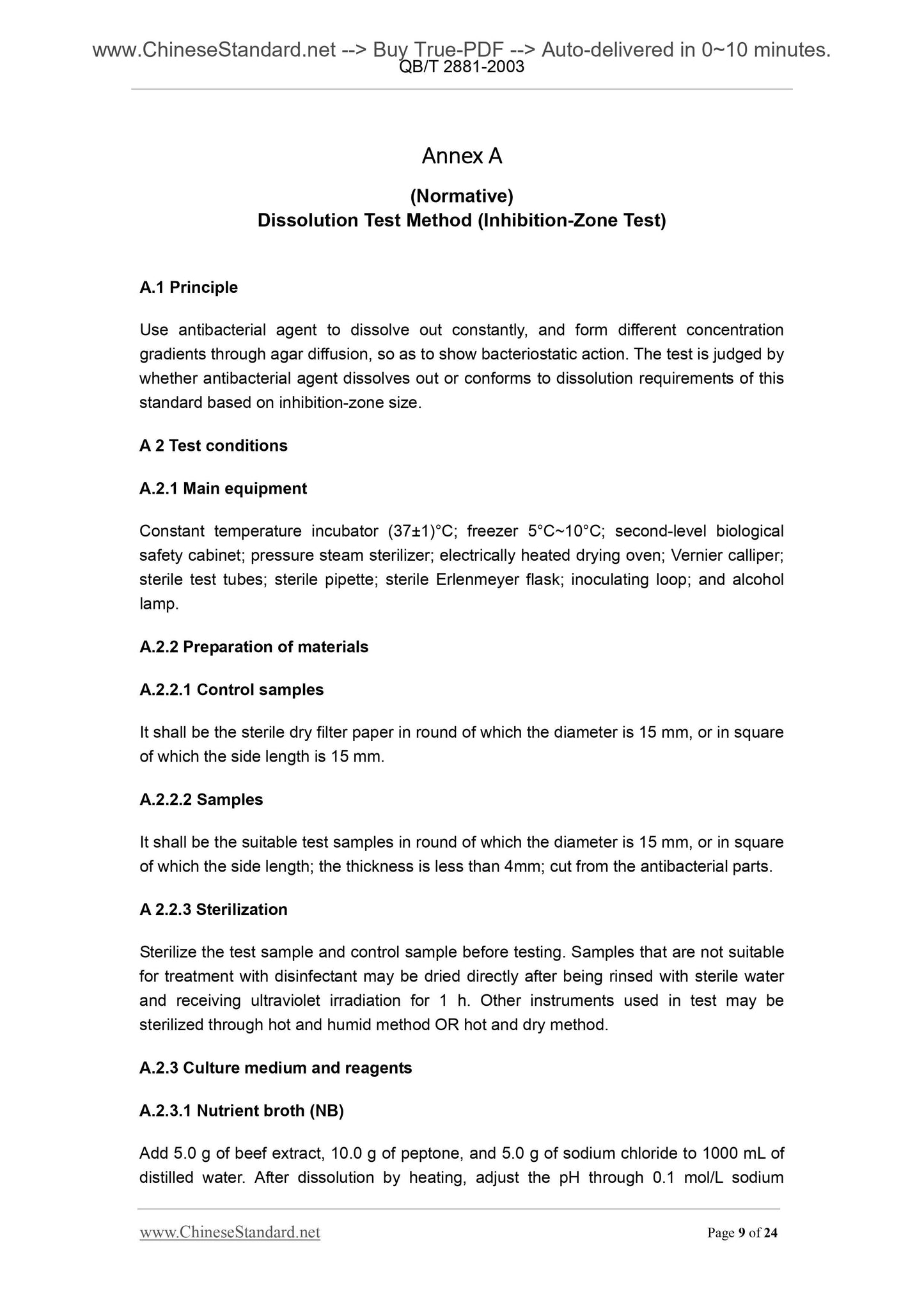

This standard specifies the terms and definitions, test environment, sampling, test strains,test method, requirements, determination, identification, and report of antibacterial

performances of footwear and footwear components.

This standard applies to footwear and footwear components with antibacterial

performance.

2 Normative references

The articles contained in the following documents have become part od this document

when they are quoted herein. For the dated documents so quoted, all the modifications

(Including all corrections) or revisions made thereafter shall be applicable to this

document.

GB 4789.2 National food safety standard Food microbiological examination. Aerobic

plate count

GB/T 8629-2001 Textiles - Domestic washing and drying procedures for textile testing

GB 19489 Laboratories - General requirements for biosafety

3 Terms and definitions

For the purpose of this standard, the following terms and definitions apply.

3.1

Antibacterial

Basic Data

| Standard ID | QB/T 2881-2013 (QB/T2881-2013) |

| Description (Translated English) | Footwear and footwear components - Antimicrobial performance specifications |

| Sector / Industry | Light Industry Standard (Recommended) |

| Classification of Chinese Standard | Y78 |

| Classification of International Standard | 61.060 |

| Word Count Estimation | 16,145 |

| Older Standard (superseded by this standard) | QB/T 2881-2007 |

| Quoted Standard | GB 4789.2; GB/T 8629-2001; GB 19489 |

| Regulation (derived from) | Ministry of Industry and Information Technology Bulletin No. 71 of 2013; industry standard for filing Notice No. 2 of 2014 (No. 170 overall) |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the terms and definitions footwear and footwear components antibacterial properties, the test environment, sampling, test strains, test methods, requirements determination, identification and reporting. This standard applies to foo |

Share