1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QB/T 2761-2006 English PDF (QB/T2761-2006)

QB/T 2761-2006 English PDF (QB/T2761-2006)

Regular price

$180.00

Regular price

Sale price

$180.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

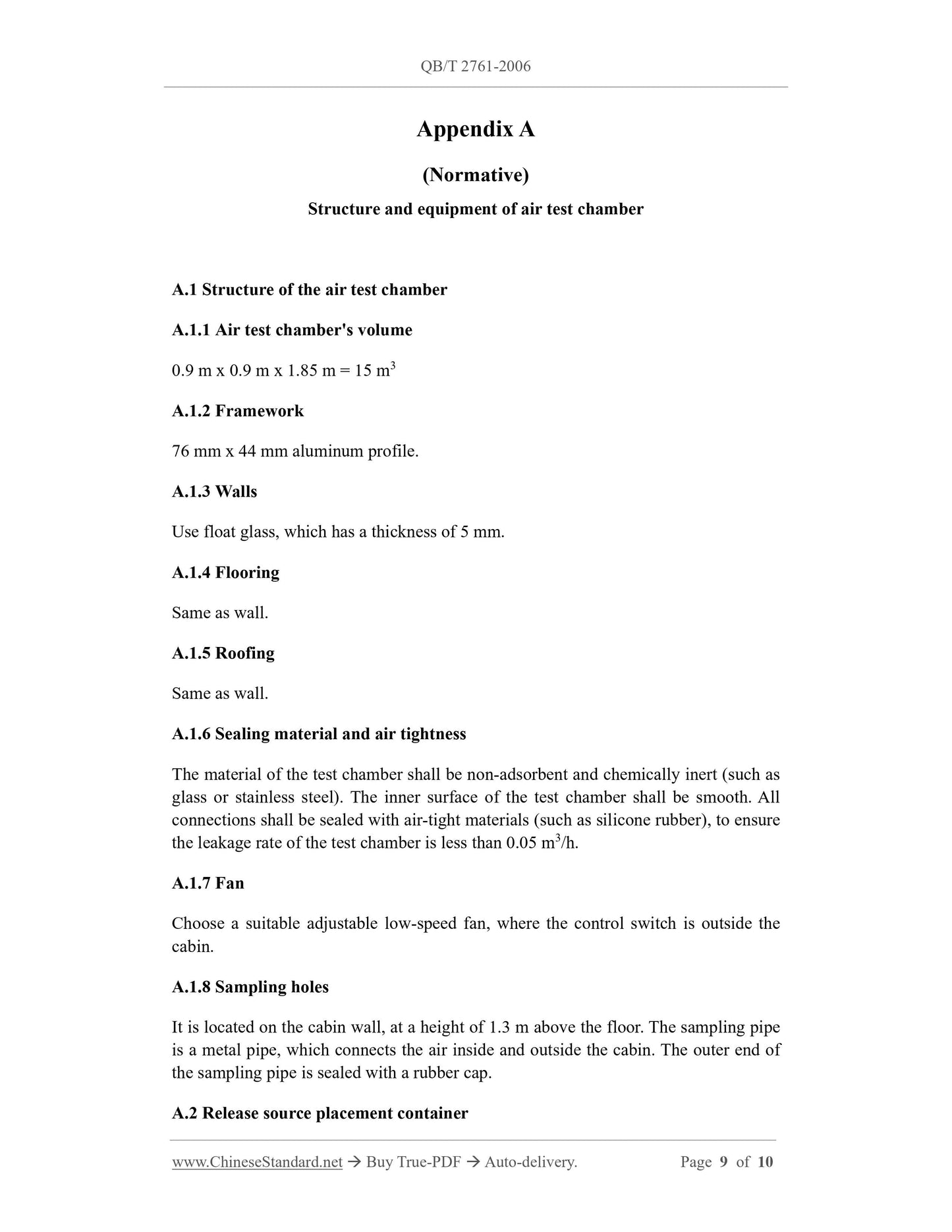

QB/T 2761-2006: Methods for determination of purificatory effect of indoor environment decontamination product

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click QB/T 2761-2006 (Self-service in 1-minute)

Newer / historical versions: QB/T 2761-2006

Preview True-PDF

Scope

This standard specifies the test methods for the determination of purificatory effect ofindoor environment decontamination product.

This standard is applicable to the determination of pollutant removal efficiency of

various indoor air passive purification materials. The active purifier is carried out

according to GB/T 18801-2002 "Air cleaner".

The determination of microbially contaminated purification products shall be carried

out in accordance with the relevant standards of the Ministry of Health.

Basic Data

| Standard ID | QB/T 2761-2006 (QB/T2761-2006) |

| Description (Translated English) | Methods for determination of purificatory effect of indoor environment decontamination product |

| Sector / Industry | Light Industry Standard (Recommended) |

| Classification of Chinese Standard | Y44 |

| Classification of International Standard | 71.100.35 |

| Word Count Estimation | 7,749 |

| Date of Issue | 2006-08-19 |

| Date of Implementation | 2006-12-01 |

| Quoted Standard | GB/T 18883-2002; GB/T 16129-1995; GB/T 18204.26-2000; GB/T 11737-1989; GB/T 18801-2002 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the indoor air purification products to remove indoor pollutants test method effect. This standard applies to all kinds of indoor air purification materials passive measurement of pollutant removal efficiency. Active purifier by GB/T 18801-2002 " air purifier " regulations. Determination of microbial contamination on the purification of the product. Accordance with the Ministry of Health standards. |

Share