1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QB/T 2537-2001 English PDF (QB/T2537-2001)

QB/T 2537-2001 English PDF (QB/T2537-2001)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

QB/T 2537-2001: Leather - Tests for colour fastness - Colour fastness to cycles of to-and-fro rubbing

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click QB/T 2537-2001 (Self-service in 1-minute)

Newer / historical versions: QB/T 2537-2001

Preview True-PDF

Scope

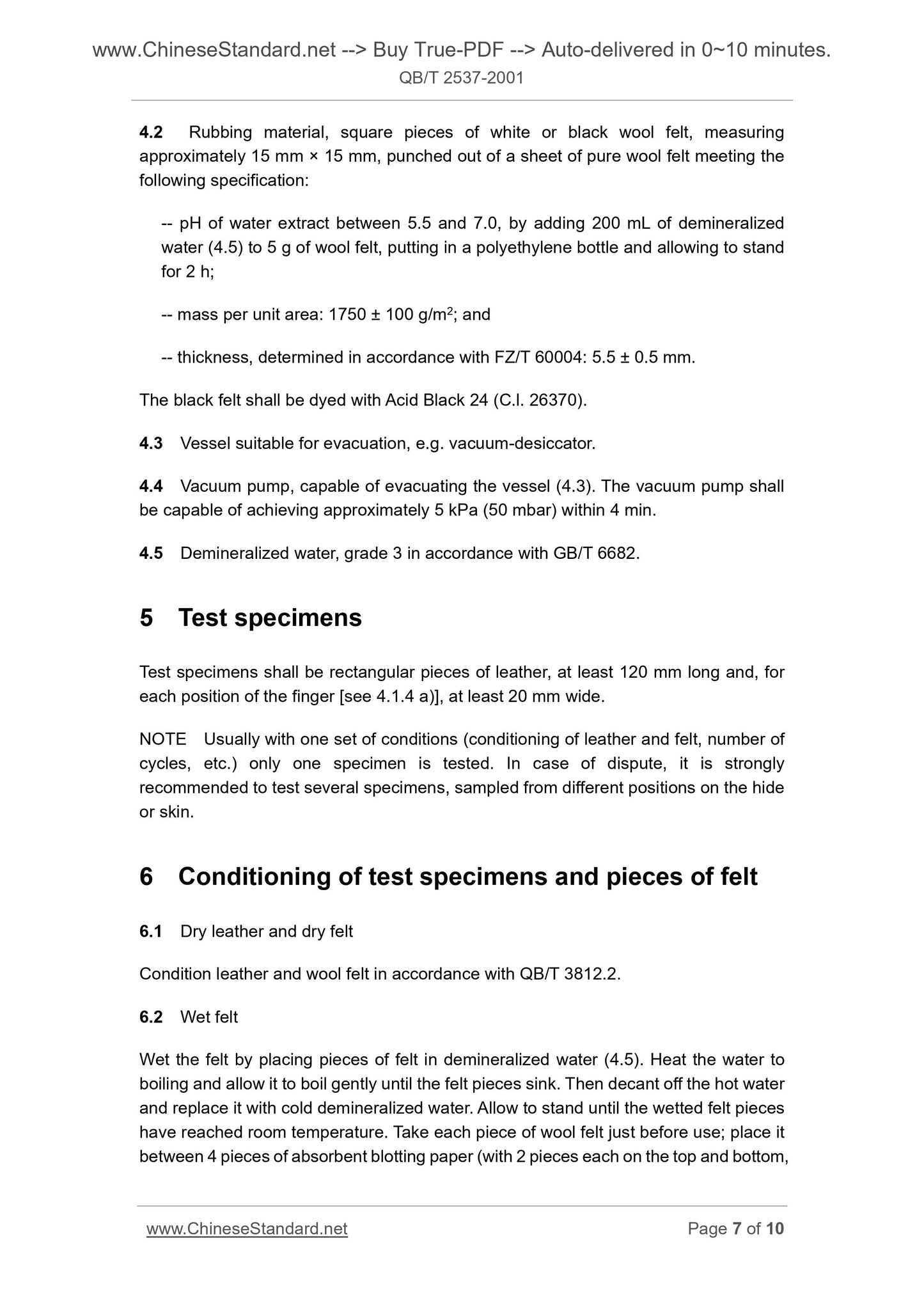

This Standard specifies a method for determining the colour fastness behaviour of thesurface of a leather on rubbing with a wool felt.

This Standard applies to leathers of all kinds.

Basic Data

| Standard ID | QB/T 2537-2001 (QB/T2537-2001) |

| Description (Translated English) | Leather - Tests for colour fastness - Colour fastness to cycles of to-and-fro rubbing |

| Sector / Industry | Light Industry Standard (Recommended) |

| Classification of Chinese Standard | Y46 |

| Word Count Estimation | 7,745 |

| Date of Issue | 2001-11-15 |

| Date of Implementation | 2002-05-01 |

| Quoted Standard | GB 250-1995; GB 251-1995; GB/T 6682-1992; QB/T 3812.2-1999; QB/T 2464.23-1999; FZ/T 60004-1991 |

| Adopted Standard | ISO 11640-1993; MOD |

| Regulation (derived from) | Industry-Science (2010) No.77 |

| Summary | This standard specifies: Felt conducted with reciprocating friction surface of the leather, leather surface friction to determine color fastness methods. This standard applies to: all kinds of leather. |

Share