1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

Q/BQB 665-2019 English PDF (Q/BQB665-2019)

Q/BQB 665-2019 English PDF (Q/BQB665-2019)

Regular price

$280.00

Regular price

Sale price

$280.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

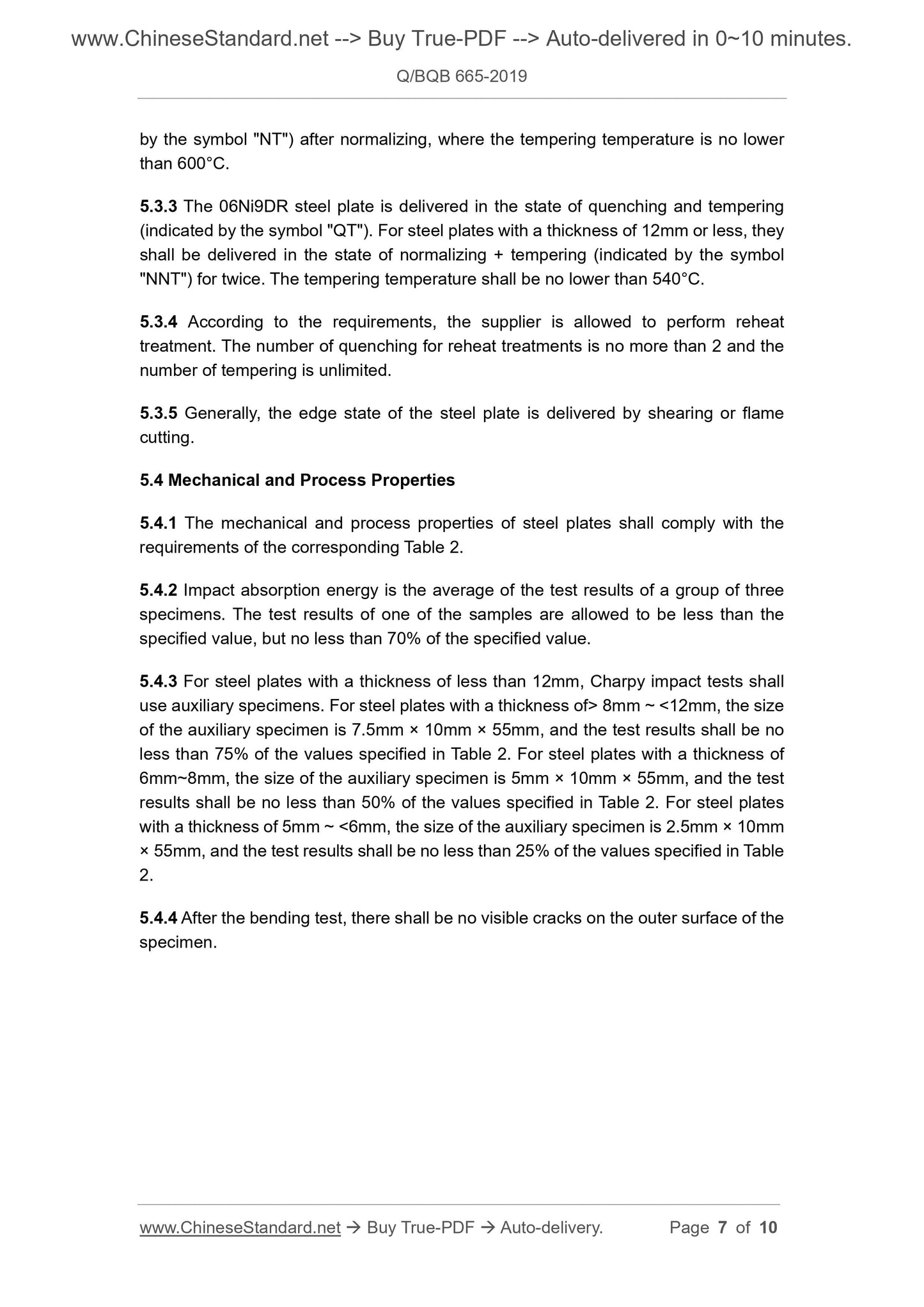

Q/BQB 665-2019: 08Ni3DR and 06Ni9DR steel plates for low temperature pressure vessels

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click Q/BQB 665-2019 (Self-service in 1-minute)

Newer / historical versions: Q/BQB 665-2019

Preview True-PDF

Scope

This Standard specifies the dimension, shape, weight, allowable deviations, technicalrequirements, inspections and tests, reinspection, package, marking and quality

certificates of 08Ni3DR and 06Ni9DR steel plates for low-temperature pressure

vessels.

This Standard is applicable to 08Ni3DR and 06Ni9DR steel plates for low-temperature

pressure vessels produced by Baoshan Iron and Steel Co., Ltd., among which

08Ni3DR has a temperature range of -100°C~100°C and thickness range of

5mm~80mm; while 06Ni9DR has a temperature range of -196°C~100°C, and

thickness range of 5mm~40mm.

Share