1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

Q/BQB 425-2014 English PDF (Q/BQB425-2014)

Q/BQB 425-2014 English PDF (Q/BQB425-2014)

Regular price

$360.00

Regular price

Sale price

$360.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Q/BQB 425-2014: Hot dip galvanized steel sheet and strip

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click Q/BQB 425-2014 (Self-service in 1-minute)

Newer / historical versions: Q/BQB 425-2014

Preview True-PDF

Scope

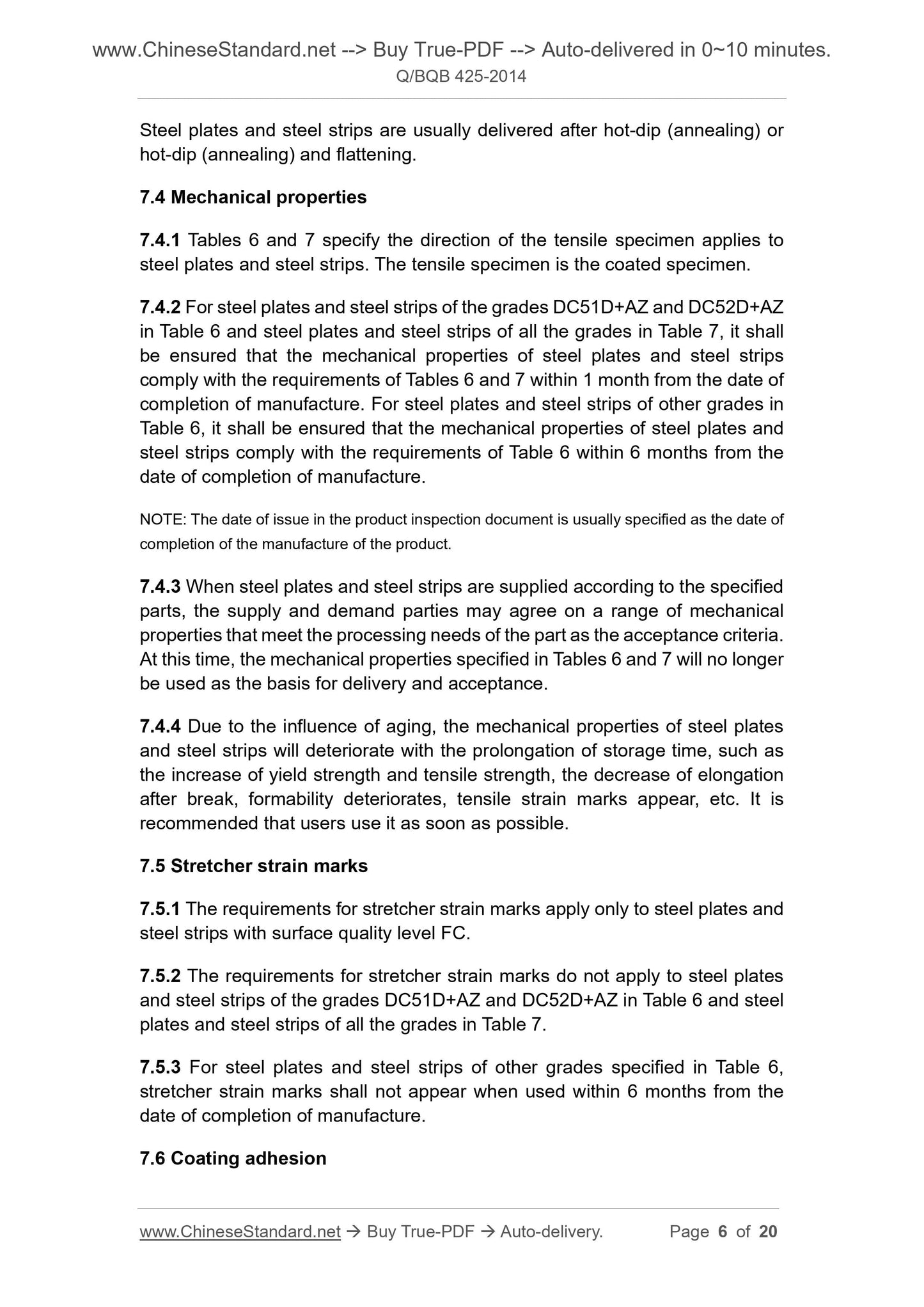

This Technical Conditions specifies the terms and definitions, classification andcode, dimension, shape, technical requirements, inspection and test,

packaging, marking and inspection documents of hot-dip aluminum-zinc alloy

coated steel plates and steel strips.

This Technical Conditions applies to hot-dip aluminum-zinc alloy coated steel

plates and steel strips with a thickness of 0.22 mm ~ 2.0 mm produced by

Baoshan Iron and Steel Co., Ltd., hereinafter referred to as steel plates and

steel strips.

Basic Data

| Standard ID | Q/BQB 425-2014 (Q/BQB425-2014) |

| Description (Translated English) | Hot dip galvanized steel sheet and strip |

| Sector / Industry | Chinese Industry Standard |

| Classification of Chinese Standard | QBQ |

| Word Count Estimation | 11,146 |

| Issuing agency(ies) | Baoshan Iron and Steel Co., Ltd. |

Share