1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

Q/BQB 418-2014 English PDF (Q/BQB418-2014)

Q/BQB 418-2014 English PDF (Q/BQB418-2014)

Regular price

$320.00

Regular price

Sale price

$320.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

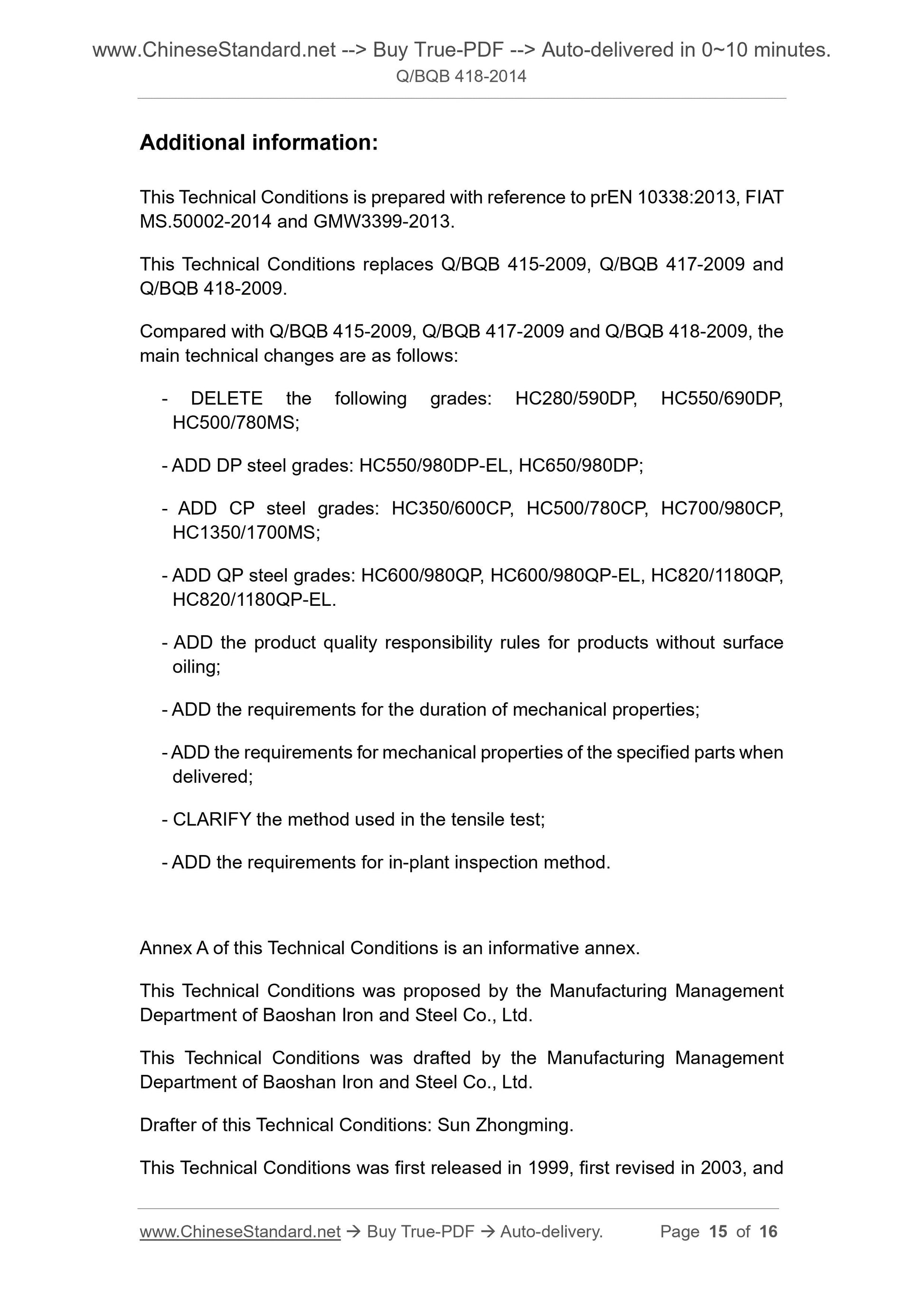

Q/BQB 418-2014: Cold-rolled advanced high-strength steel plate and strip

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click Q/BQB 418-2014 (Self-service in 1-minute)

Newer / historical versions: Q/BQB 418-2014

Preview True-PDF

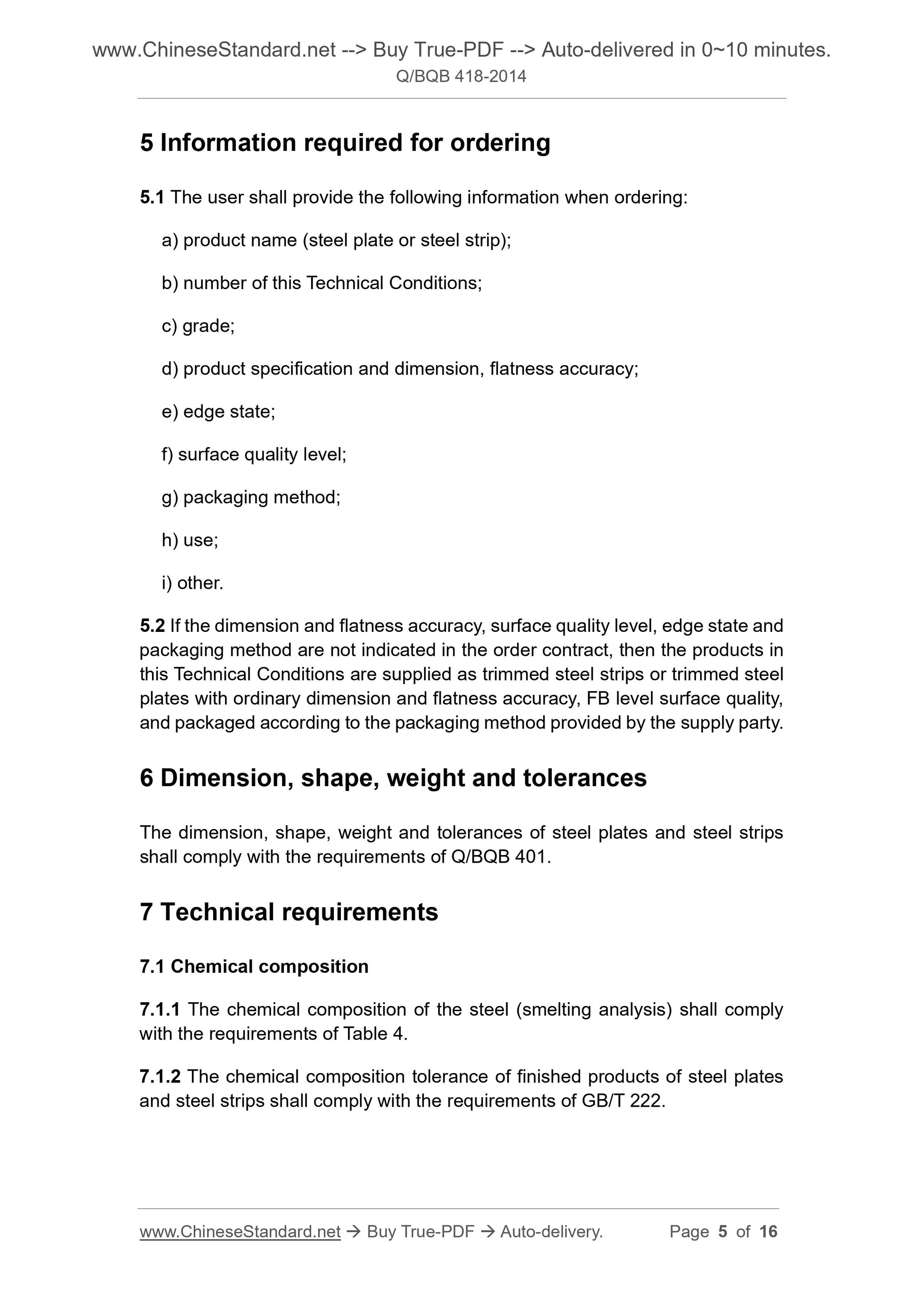

Scope

This Technical Conditions specifies the terms and definitions, classification andcode, dimension, shape, weight, technical requirements, inspection and test,

packaging, marking and inspection documents of cold-rolled advanced high-

strength steel plates and steel strips.

This Technical Conditions applies to cold-rolled advanced high-strength steel

plates and steel strips with a thickness of 0.50 mm ~ 2.3 mm (hereinafter

referred to as steel plates and steel strips) produced by Baoshan Iron and Steel

Co., Ltd.

Basic Data

| Standard ID | Q/BQB 418-2014 (Q/BQB418-2014) |

| Description (Translated English) | Cold-rolled advanced high-strength steel plate and strip |

| Sector / Industry | Chinese Industry Standard |

| Classification of Chinese Standard | QBQ |

| Word Count Estimation | 9,947 |

| Issuing agency(ies) | Baoshan Iron and Steel Co., Ltd. |

Share