1

/

of

6

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

Q/BQB 266-2020 English PDF (QBQB266-2020)

Q/BQB 266-2020 English PDF (QBQB266-2020)

Regular price

$245.00 USD

Regular price

Sale price

$245.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds (Download full-editable-PDF + Invoice).

Quotation: Click Q/BQB 266-2020>>Add to cart>>Quote

Editable-PDF Preview (Reload if blank, scroll for next page)

See Chinese contents: Q/BQB 266-2020

Q/BQB 266-2020: Corrosion resistant 13Cr martensitic stainless steel tubing and casing

Read this Google-Book: Q/BQB 266-2020

Buy this Google-Book: Q/BQB 266-2020

Germany Google-Book: Q/BQB 266-2020

Japan Google-Book: Q/BQB 266-2020

Korea Google-Book: Q/BQB 266-2020

Quotation: Click Q/BQB 266-2020>>Add to cart>>Quote

Editable-PDF Preview (Reload if blank, scroll for next page)

See Chinese contents: Q/BQB 266-2020

Q/BQB 266-2020: Corrosion resistant 13Cr martensitic stainless steel tubing and casing

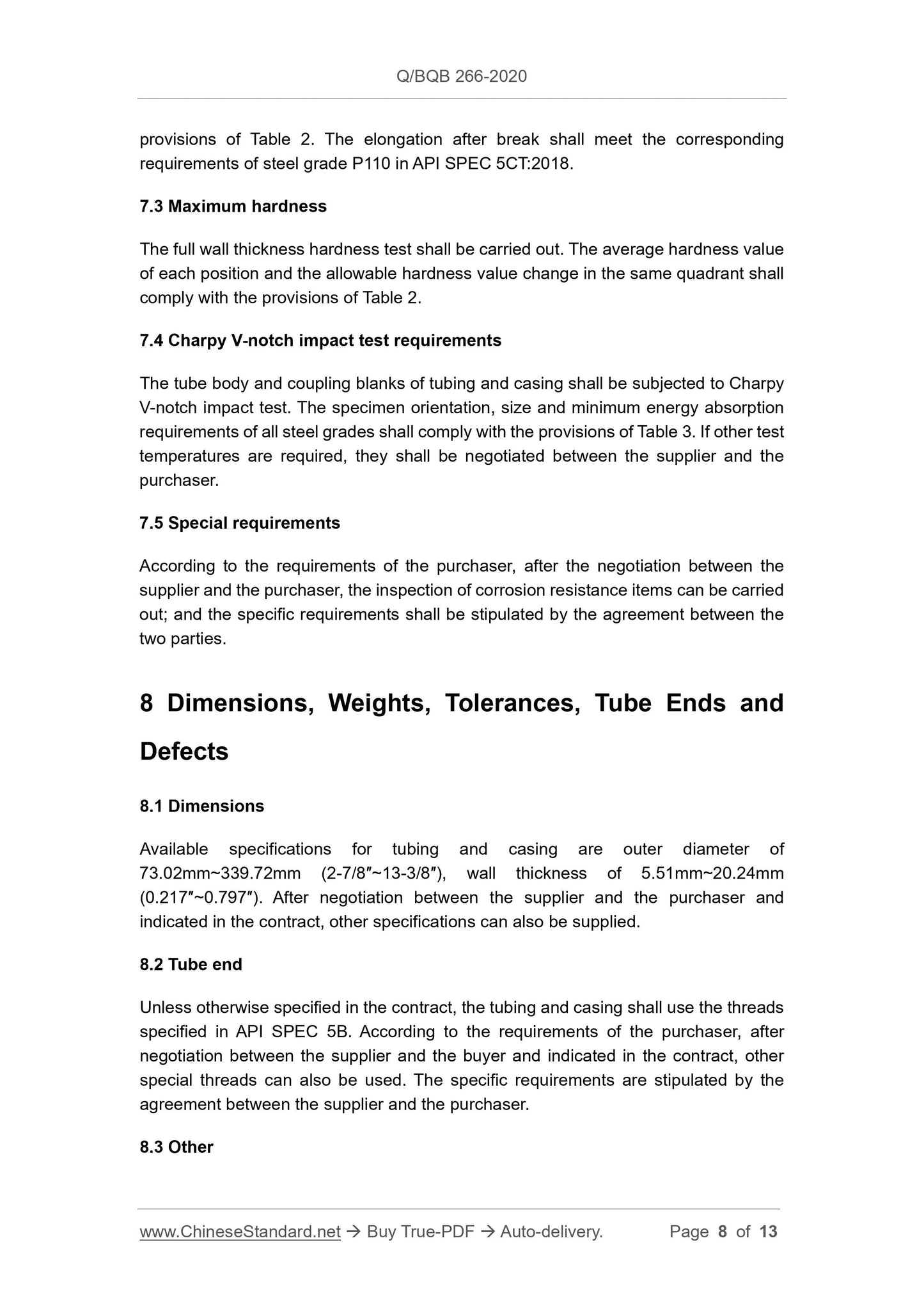

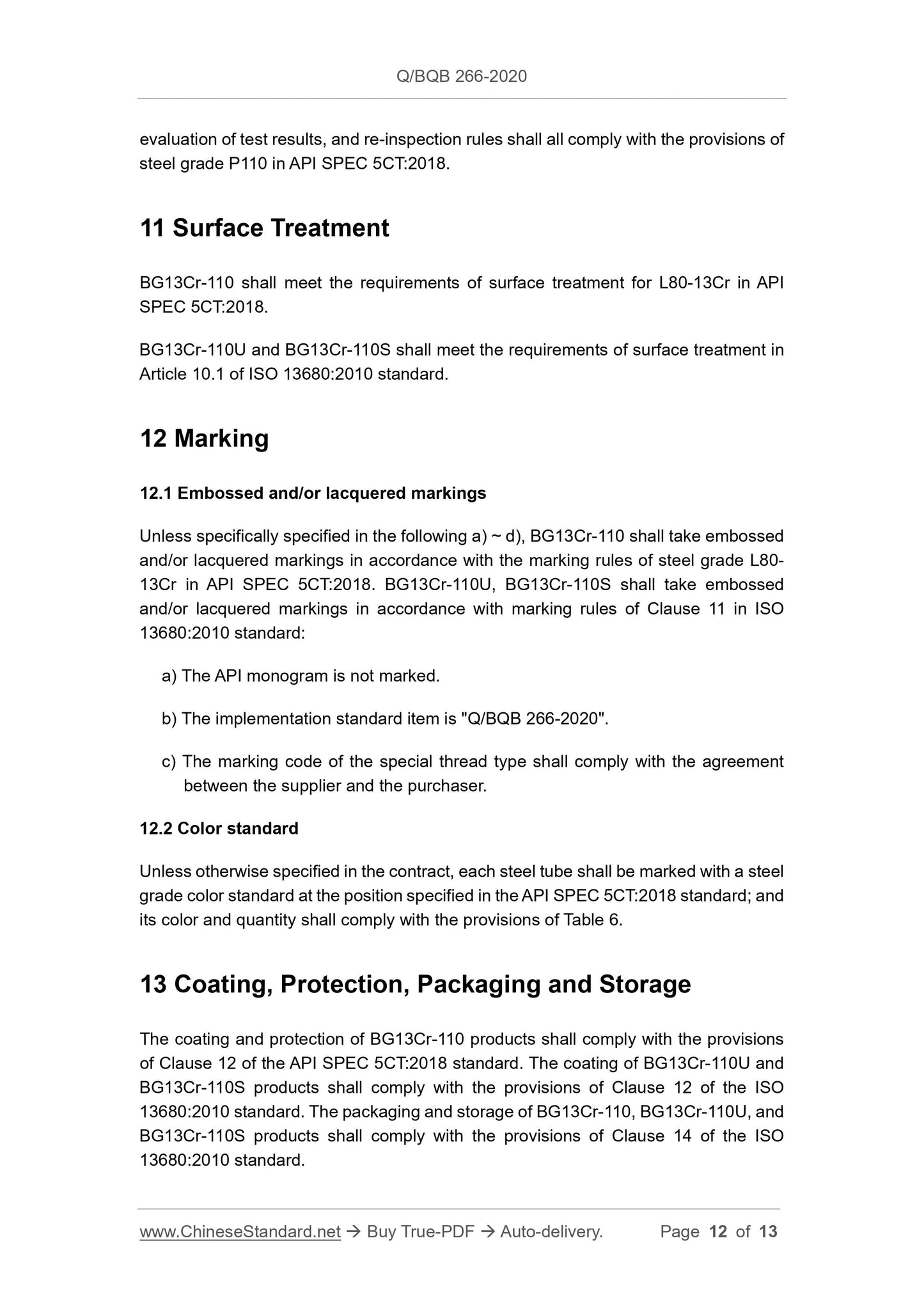

This Standard specifies the technical delivery conditions for corrosion resistant 13Cr martensitic stainless-steel tubing and casing manufactured by Baoshan Iron and Steel Co., Ltd. This Standard is applicable to seamless tubing and casing (hereinafter referred to as tubing and casing) used in CO2-containing oil and gas environments in oil and gas exploration of the petroleum and natural gas industry.

Read this Google-Book: Q/BQB 266-2020

Buy this Google-Book: Q/BQB 266-2020

Germany Google-Book: Q/BQB 266-2020

Japan Google-Book: Q/BQB 266-2020

Korea Google-Book: Q/BQB 266-2020

Share