1

/

of

7

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

Q/BQB 263-2018 English PDF (Q/BQB263-2018)

Q/BQB 263-2018 English PDF (Q/BQB263-2018)

Regular price

$280.00

Regular price

Sale price

$280.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

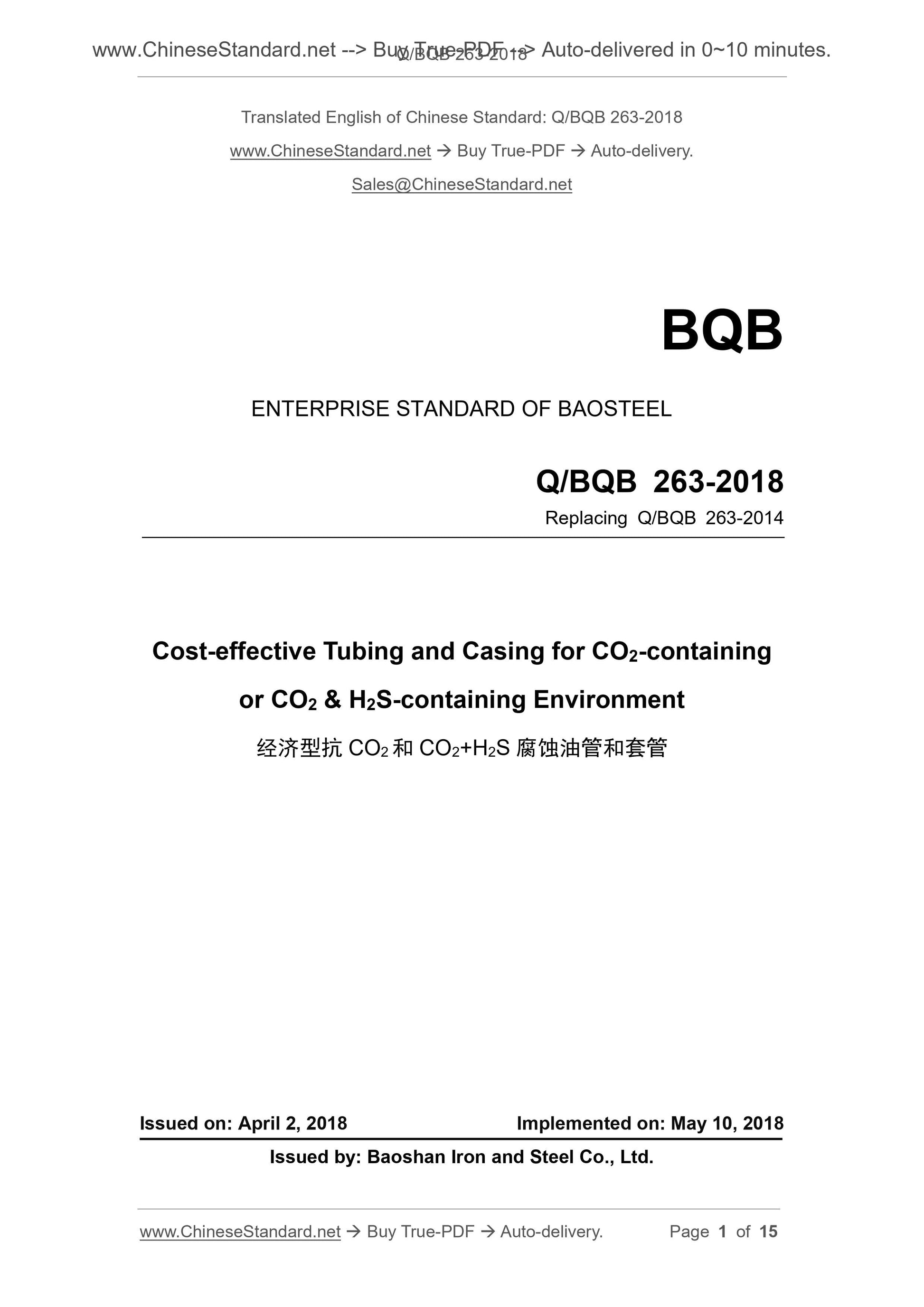

Q/BQB 263-2018: Cost-effective tubing and casing for CO2-containing or CO2 and H2S-containing environment

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click Q/BQB 263-2018 (Self-service in 1-minute)

Newer / historical versions: Q/BQB 263-2018

Preview True-PDF

Scope

This Standard specifies the technical delivery conditions of cost-effective tubing andcasing for CO2-containing or CO2 + H2S-containing environment for Baoshan Iron and

Steel Co., Ltd.

This Standard is applicable to cost-effective seamless tubing and casing (hereinafter

referred to as tubing and casing) that is applied under medium or mild CO2-containing

corrosive environment or CO2 + H2S-containing compound corrosive environment in oil

and gas exploitation in the petroleum and natural gas industry.

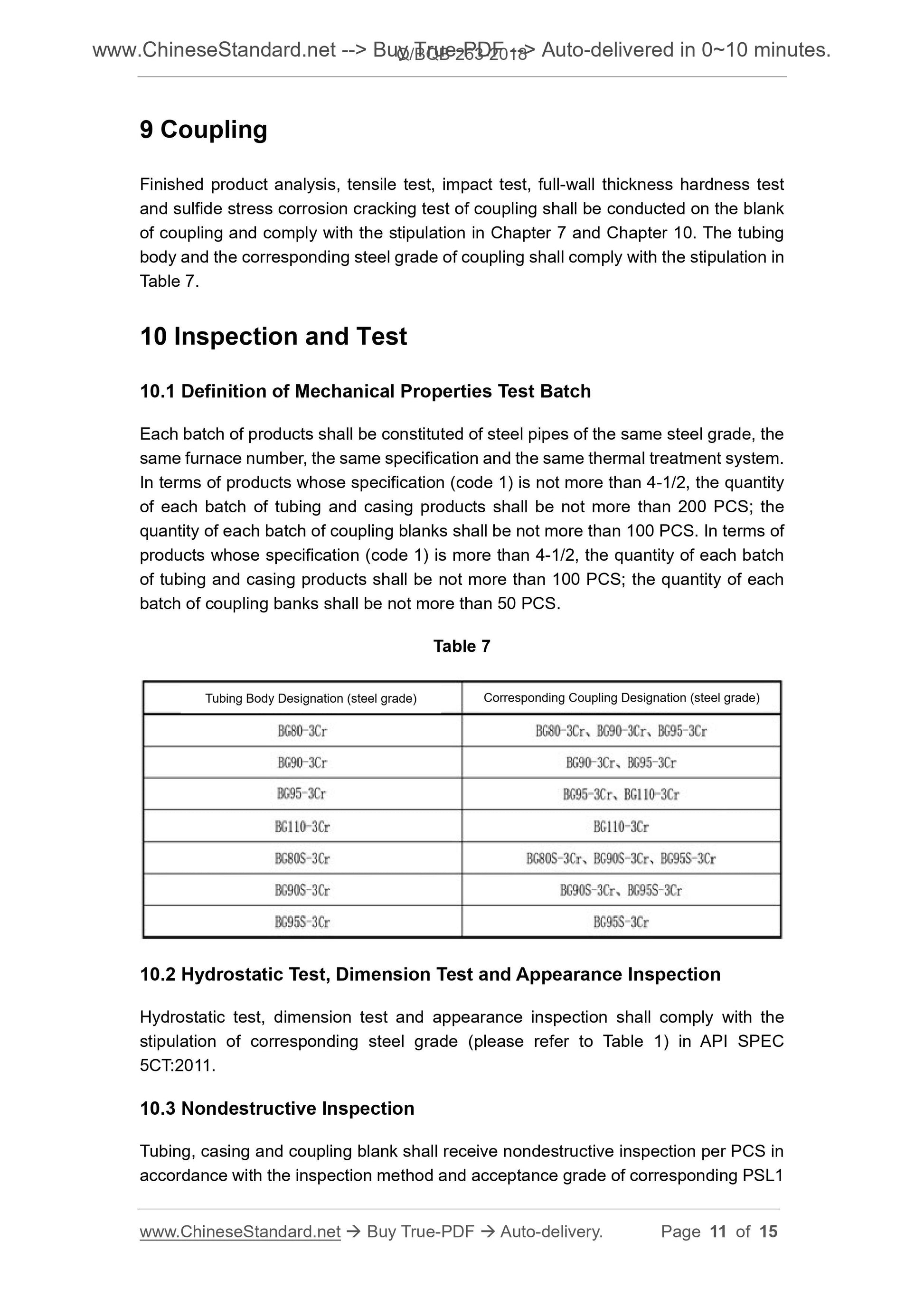

In this Standard, steel grades of tubing and casing are. BG80-3Cr, BG90-3Cr, BG95-

3Cr and BG110-3Cr, which are applicable to CO2-containing corrosive environment;

BG80S-3Cr, BG90S-3Cr and BG95S-3Cr, which are applicable to CO2 + H2S-

containing compound corrosive environment.

Tubing and casing that are stipulated in this Standard include three product

specification levels (PSL1, PSL2 and PSL3).

Basic Data

| Standard ID | Q/BQB 263-2018 (Q/BQB263-2018) |

| Description (Translated English) | Cost-effective tubing and casing for CO2-containing or CO2 and H2S-containing environment |

| Sector / Industry | Chinese Industry Standard |

| Classification of Chinese Standard | QBQ |

| Word Count Estimation | 12,138 |

| Issuing agency(ies) | Baoshan Iron and Steel Co., Ltd. |

Share