1

/

of

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

NB/T 47010-2010 English PDF (NB/T47010-2010)

NB/T 47010-2010 English PDF (NB/T47010-2010)

Regular price

$95.00

Regular price

Sale price

$95.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

NB/T 47010-2010: Stainless and heat-resisting steel forgings for pressure equipment

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click NB/T 47010-2010 (Self-service in 1-minute)

Newer / historical versions: NB/T 47010-2010

Preview True-PDF

Scope

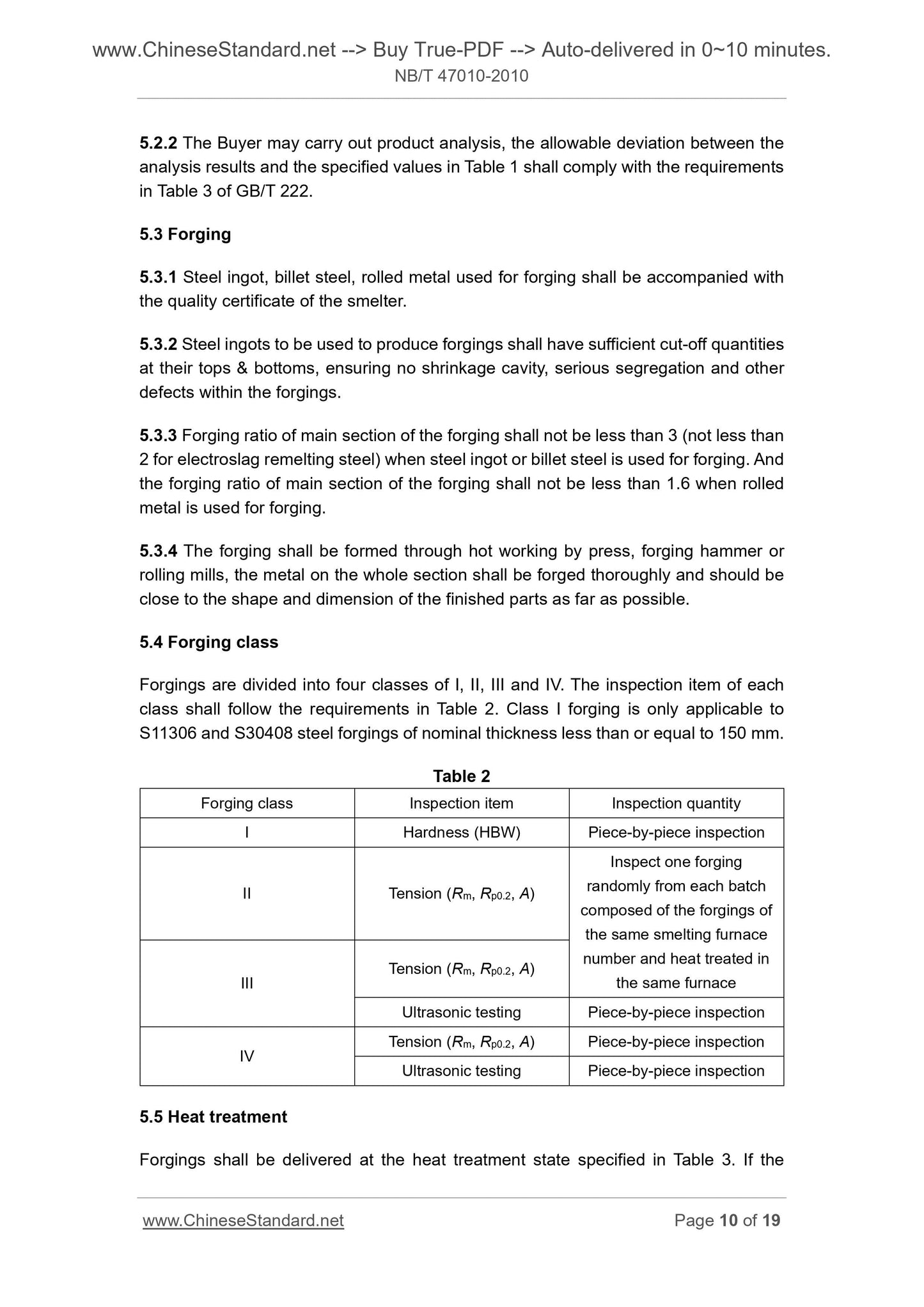

This Standard specifies the technical requirements, test methods and inspection rulesof stainless and heat-resisting steel forgings for the pressure equipment’s.

This Standard is applicable to the stainless and heat-resisting steel forgings for

pressure equipment’s with a design pressure less than 100 MPa.

Basic Data

| Standard ID | NB/T 47010-2010 (NB/T47010-2010) |

| Description (Translated English) | Stainless and heat-resisting steel forgings for pressure equipment |

| Sector / Industry | Energy Industry Standard (Recommended) |

| Classification of Chinese Standard | J32 |

| Classification of International Standard | 77.140.85 |

| Word Count Estimation | 13,163 |

| Date of Issue | 2010-08-27 |

| Date of Implementation | 2011-12-15 |

| Older Standard (superseded by this standard) | JB 4728-2000 |

| Quoted Standard | GB/T 222-2006; GB/T 223; GB/T 228; GB/T 231.1; GB/T 6394; GB/T 10561; GB/T 11170; GB/T 20066; JB/T 4730.3 |

| Regulation (derived from) | ?National Energy Board Announcement 2010 No.3 |

| Issuing agency(ies) | National Energy Administration |

| Summary | This standard specifies the pressure equipment with stainless and heat-resisting steel forgings technical requirements, test methods and inspection rules. This standard applies to the design pressure of less than 100MPa pressure equipment with stainless steel and heat-resistant steel plating. |

Share