1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JJG 162-2009 English PDF

JJG 162-2009 English PDF

Regular price

$920.00

Regular price

Sale price

$920.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

JJG 162-2009: Verification Regulation of Cold Water Meter

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click JJG 162-2009 (Self-service in 1-minute)

Newer / historical versions: JJG 162-2009

Preview True-PDF

Scope

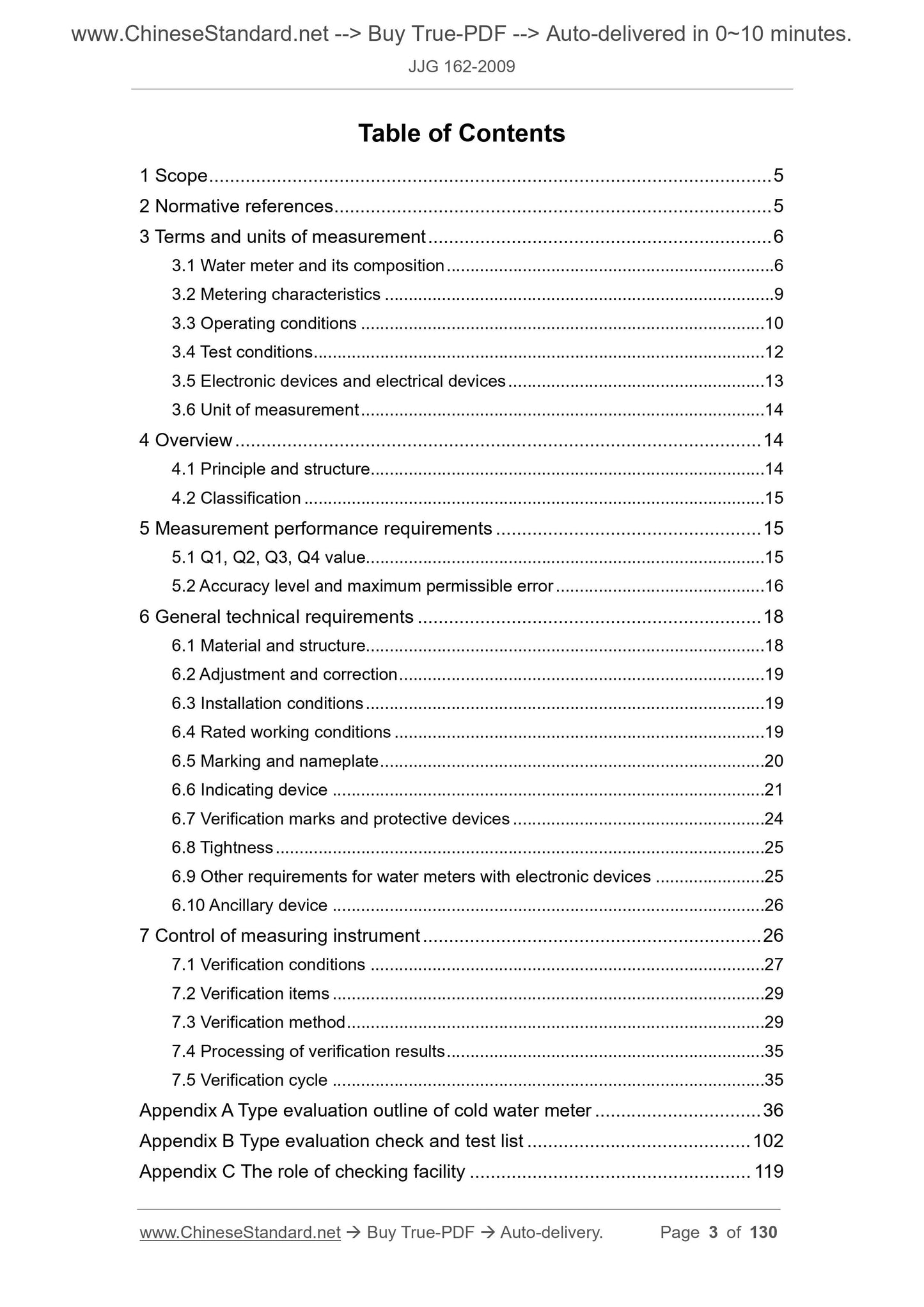

This regulation is applicable to the type evaluation, first verification, subsequentverification and in-use inspection of cold water meters.

The cold water meter referred to in this regulation is a water meter that

measures clean cold water flowing through a closed pipe and has a temperature

of T30 or T50, including mechanical water meters, mechanical water meters

equipped with electronic devices, water meters based on electromagnetic or

electronic principles.

Basic Data

| Standard ID | JJG 162-2009 (JJG162-2009) |

| Description (Translated English) | Verification Regulation of Cold Water Meter |

| Sector / Industry | Metrology and Measurement Industry Standard |

| Classification of Chinese Standard | A53 |

| Classification of International Standard | 17.120 |

| Word Count Estimation | 91,950 |

| Date of Issue | 2009-04-08 |

| Date of Implementation | 2009-04-30 |

| Older Standard (superseded by this standard) | JJG 162-2007 |

| Adopted Standard | OIML R49-1-2006, NEQ; OIML R49-2-2006, NEQ |

| Regulation (derived from) | AQSIQ Announcement No. 27 of 2009 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine |

| Summary | This standard applies to cold water meter type evaluation, initial verification, testing and use of follow-up inspection. The procedures referred to in cold water meter for measuring the flow through closed conduits clean water, temperature class T30 or T50 of the meter, including mechanical meter, equipped with electronic devices mechanical meter, based on the principle of electromagnetic or electronic meter work. |

Share