1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JJF 1835-2020 English PDF

JJF 1835-2020 English PDF

Regular price

$405.00

Regular price

Sale price

$405.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

JJF 1835-2020: Calibration Specification for Terrestrial Laser Scanners

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click JJF 1835-2020 (Self-service in 1-minute)

Newer / historical versions: JJF 1835-2020

Preview True-PDF

Scope

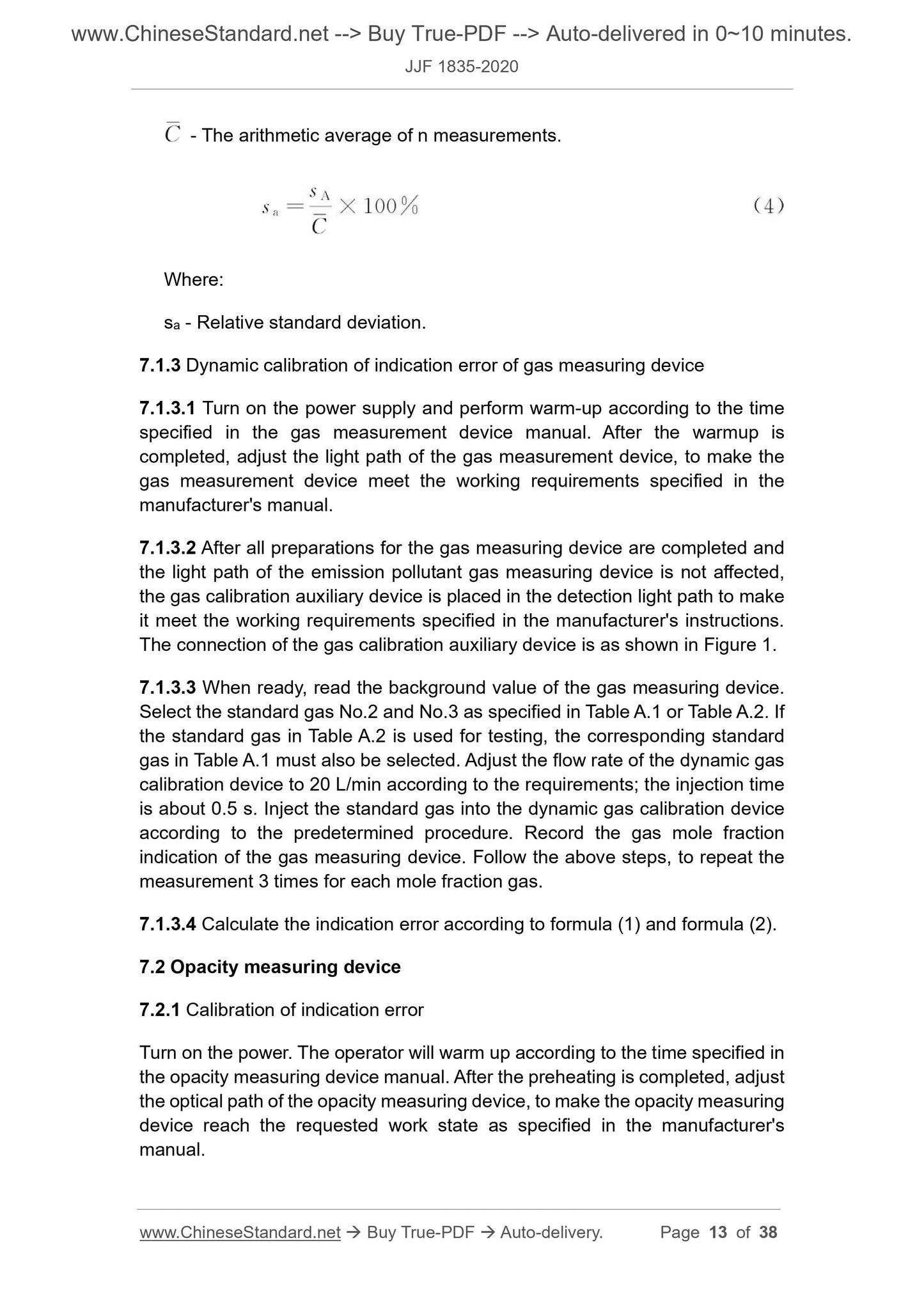

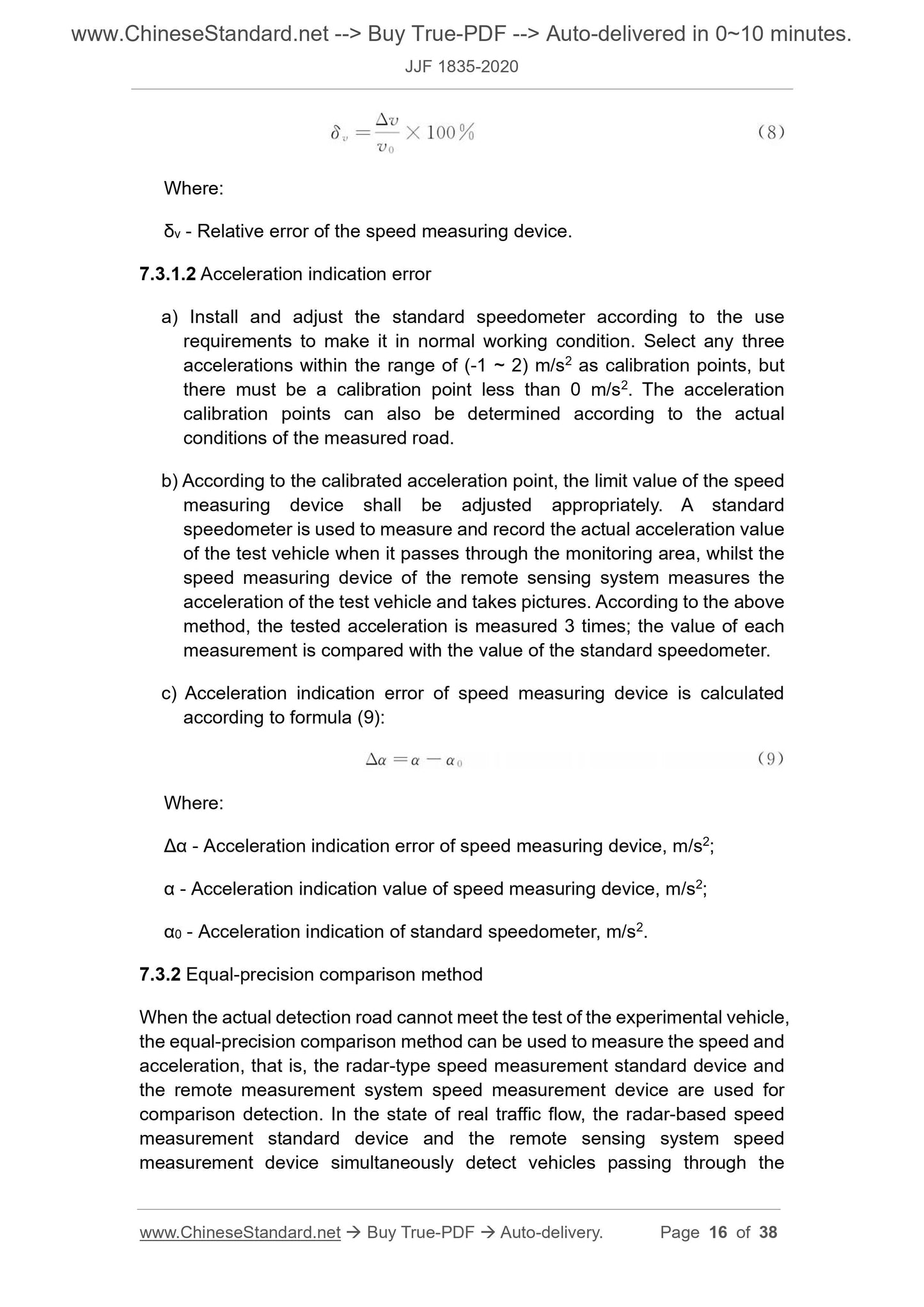

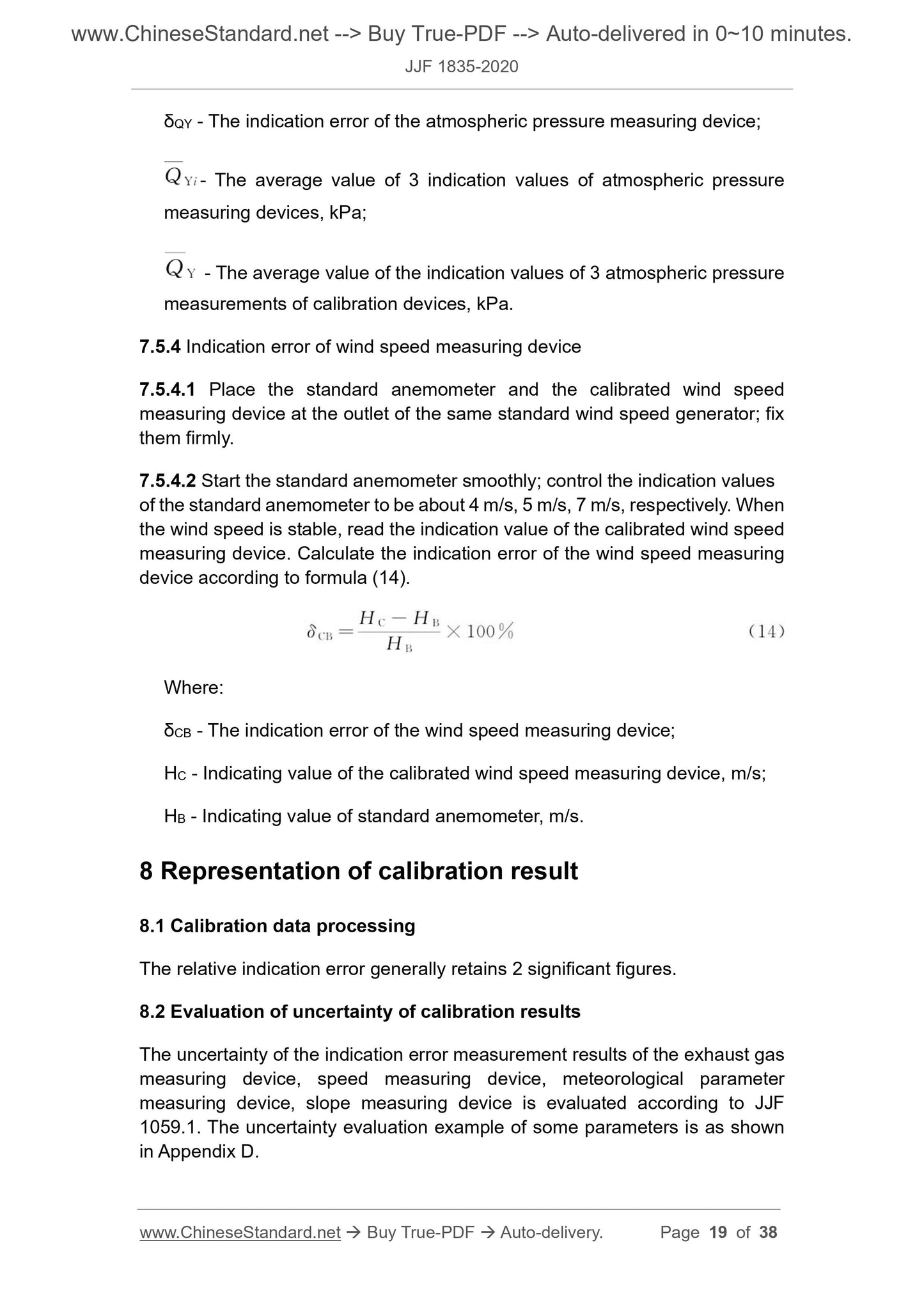

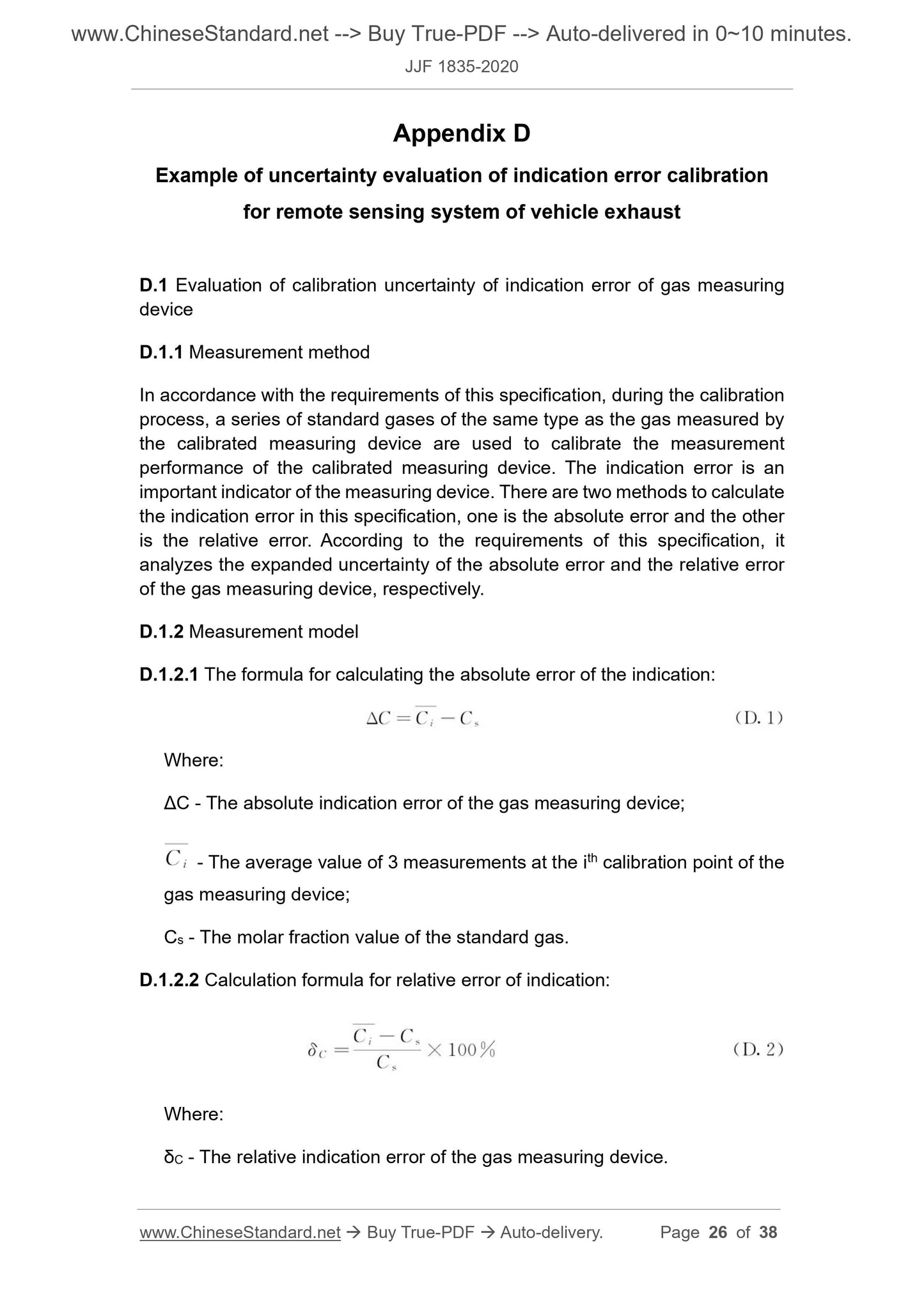

This specification applies to the calibration of the remote sensing measurementsystem for motor vehicle exhaust.

Basic Data

| Standard ID | JJF 1835-2020 (JJF1835-2020) |

| Description (Translated English) | Calibration Specification for Terrestrial Laser Scanners |

| Sector / Industry | Metrology and Measurement Industry Standard |

| Classification of Chinese Standard | A50 |

| Word Count Estimation | 30,364 |

| Date of Issue | 2020-07-02 |

| Date of Implementation | 2020-10-02 |

| Regulation (derived from) | Announcement No. 29 (2020) of the State Administration for Market Regulation |

| Issuing agency(ies) | State Administration for Market Regulation |

Share