1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JC/T 764-2008 English PDF (JC/T764-2008)

JC/T 764-2008 English PDF (JC/T764-2008)

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

JC/T 764-2008: WC seats

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click JC/T 764-2008 (Self-service in 1-minute)

Newer / historical versions: JC/T 764-2008

Preview True-PDF

Scope

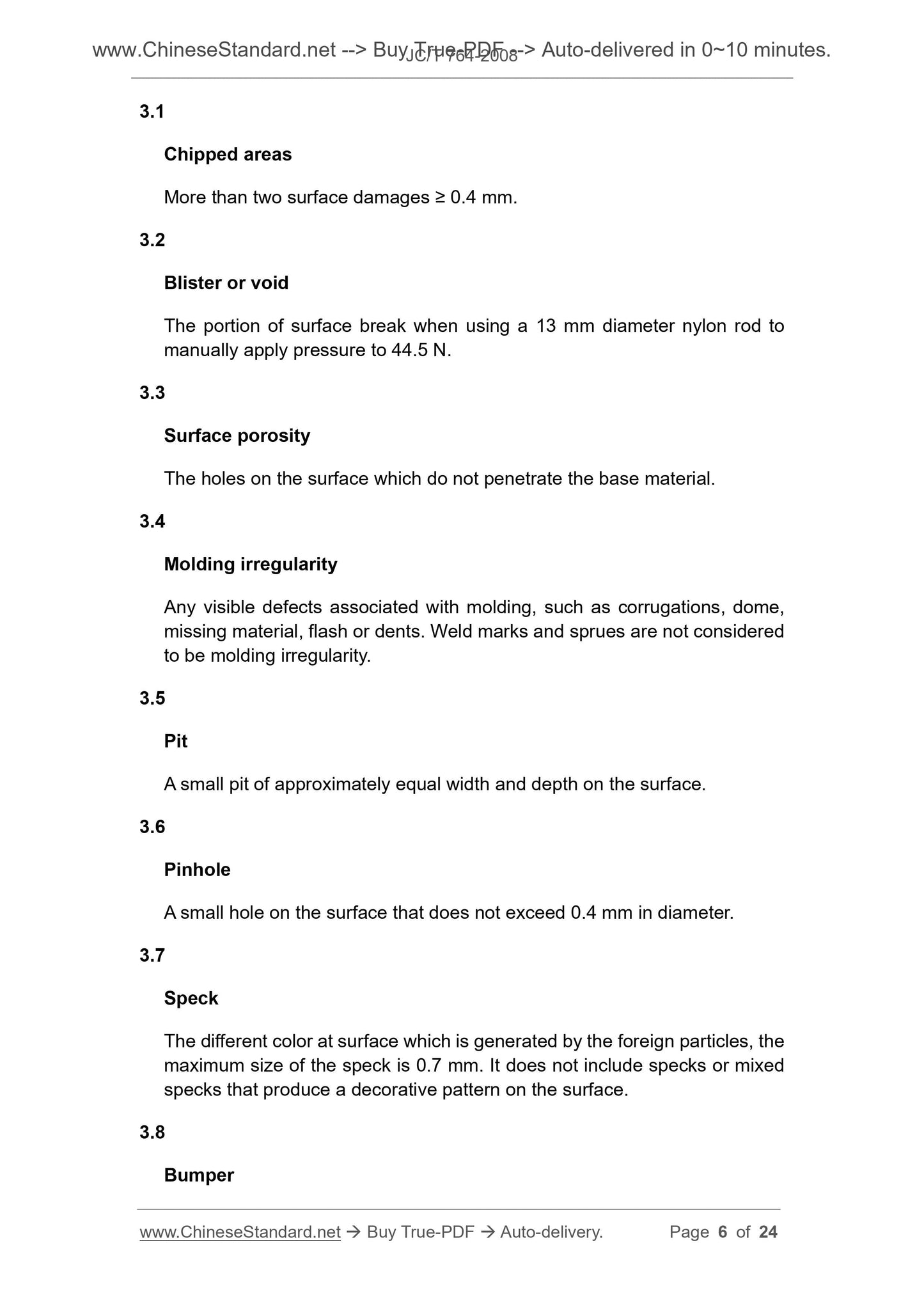

This standard specifies the terms and definitions, classification, requirements,test methods, inspection rules, markings, operation instructions, packaging,

transportation and storage of WC seats.

This standard is applicable to the WC seats which are made of plastic, wood,

composite materials, resin and other materials, installed on the surface of the

pedestal pan, are comfortable, hygienic and beautiful (hereinafter referred to as

the WC seats).

Basic Data

| Standard ID | JC/T 764-2008 (JC/T764-2008) |

| Description (Translated English) | WC seats |

| Sector / Industry | Building Materials Industry Standard (Recommended) |

| Classification of Chinese Standard | Q31 |

| Classification of International Standard | 91.140.70 |

| Word Count Estimation | 15,150 |

| Date of Issue | 2008-06-16 |

| Date of Implementation | 2008-12-01 |

| Older Standard (superseded by this standard) | JC/T 764-2001 |

| Quoted Standard | GB/T 2829; GB/T 4892; GB/T 6388; GB/T 6461; GB/T 6739; GB/T 9286; GB/T 10125 |

| Adopted Standard | ANSI Z124.5-1997, MOD |

| Regulation (derived from) | ?National Development and Reform Commission Announcement 2008 No.44 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the toilet seat ring and cover terminology and definitions, classification, requirements, test methods, inspection rules, signs, manual, packaging, transport and storage. This standard applies to the use of surface mounted toilet, from the comfort, health, aesthetic effects of plastic, wood, composite materials, resin and other materials processed into toilet seat ring and cover. |

Share