1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JC/T 2625-2021 English PDF (JC/T2625-2021)

JC/T 2625-2021 English PDF (JC/T2625-2021)

Regular price

$110.00

Regular price

Sale price

$110.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

JC/T 2625-2021: Titanium gypsum

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click JC/T 2625-2021 (Self-service in 1-minute)

Newer / historical versions: JC/T 2625-2021

Preview True-PDF

Scope

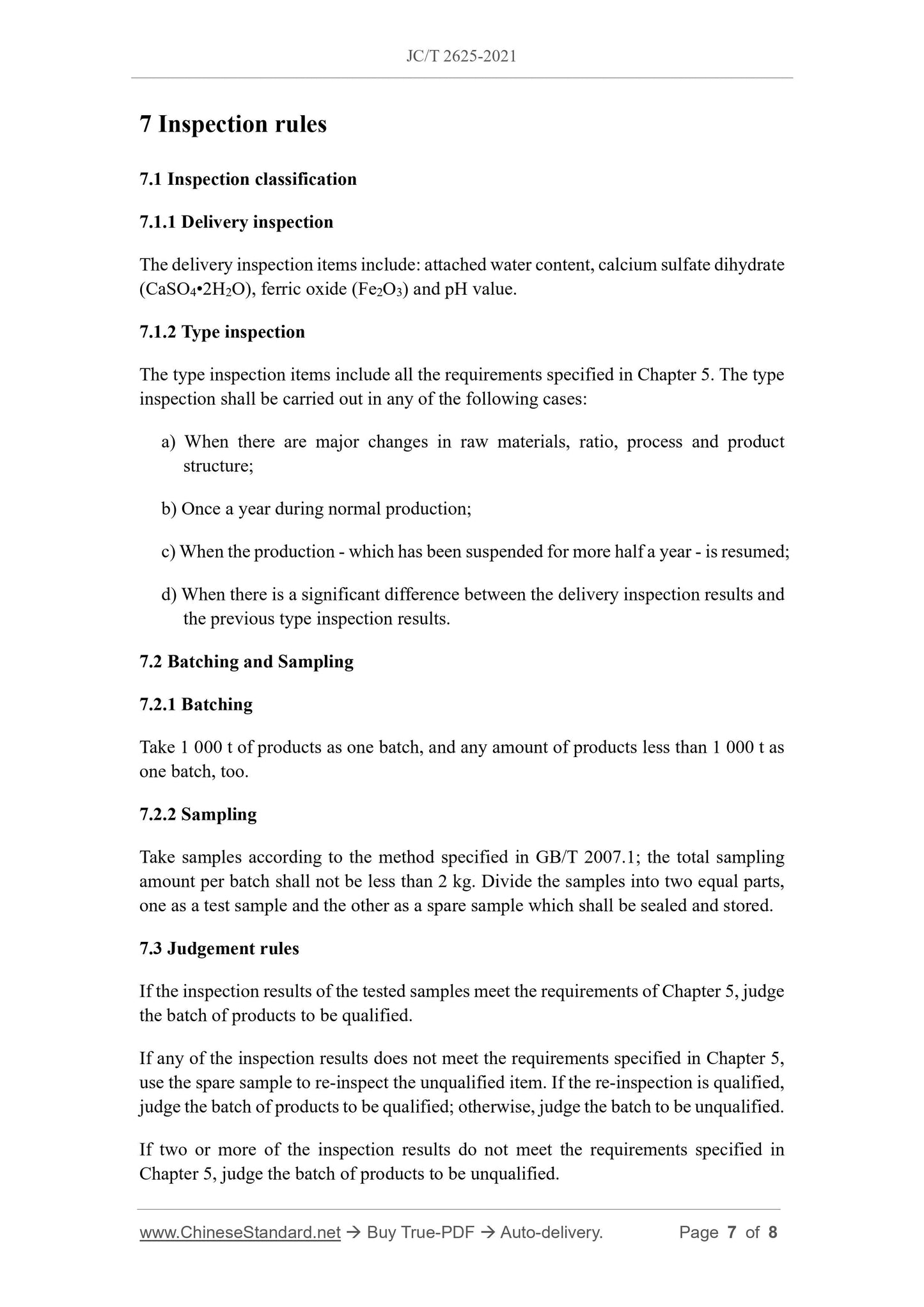

This document specifies the classification and labeling, requirements, test methods,inspection rules and packaging, marking, transportation and storage of titanium gypsum.

This document applies to the titanium gypsum - with calcium sulfate dihydrate as the

main component - that is produced by the neutralization of limestone powder, lime,

carbide slag AND acidic wastewater during the production of titanium dioxide by the

sulfuric acid method.

Basic Data

| Standard ID | JC/T 2625-2021 (JC/T2625-2021) |

| Description (Translated English) | Titanium gypsum |

| Sector / Industry | Building Materials Industry Standard (Recommended) |

| Classification of Chinese Standard | Q62 |

| Word Count Estimation | 6,641 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

Share