1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JC/T 1088-2008 English PDF (JC/T1088-2008)

JC/T 1088-2008 English PDF (JC/T1088-2008)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

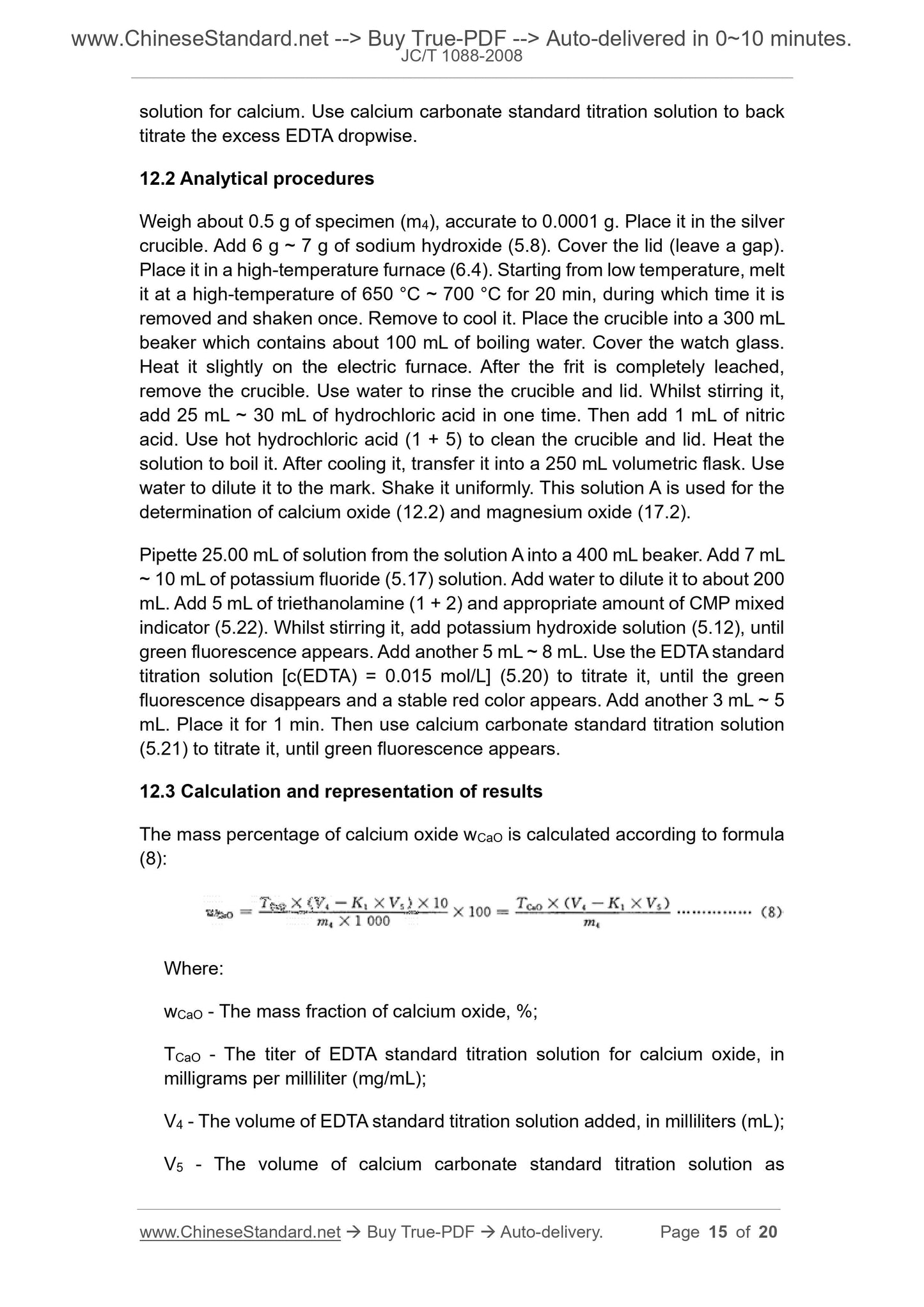

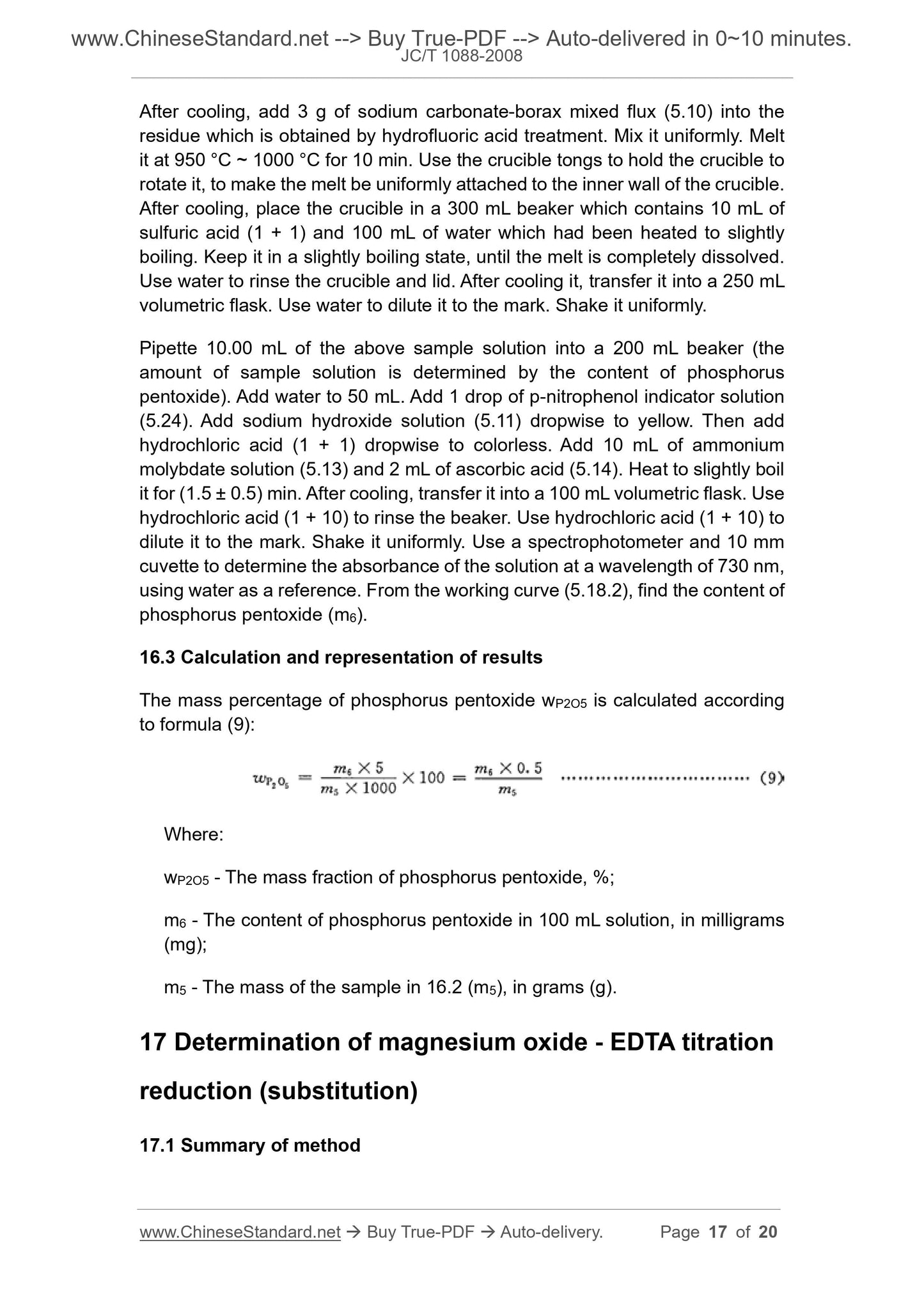

JC/T 1088-2008: Methods for chemical analysis of granulated electric furnace phosphorous slag

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click JC/T 1088-2008 (Self-service in 1-minute)

Newer / historical versions: JC/T 1088-2008

Preview True-PDF

Scope

This standard specifies the benchmark method and substitution method for themethod of chemical analysis of granulated electric furnace phosphorus slag. In

case of dispute, the benchmark method shall prevail.

This standard applies to the granulated electric furnace phosphorus slag used

in the building materials industry and other materials designated to adopt this

standard.

Basic Data

| Standard ID | JC/T 1088-2008 (JC/T1088-2008) |

| Description (Translated English) | High silica glass filament yarn |

| Sector / Industry | Building Materials Industry Standard (Recommended) |

| Classification of Chinese Standard | Q36 |

| Classification of International Standard | 91.100.10 |

| Word Count Estimation | 11,113 |

| Date of Issue | 2008-06-16 |

| Date of Implementation | 2008-12-01 |

| Quoted Standard | GB/T 2007.1; GB/T 6682; GB/T 176-2008 |

| Adopted Standard | EN 196-2-2005, NEQ; ASTM C114-2005, NEQ |

| Regulation (derived from) | ?Development and Reform Commission Announcement 2008 No.44; |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the method of analysis of granulated furnace slag chemistry of phosphorus -based approach and generation of usage. In case of dispute, the reference method to prevail. This standard applies to the building materials industry with granulated phosphorus furnace slag and other materials specified in this standard. |

Share