1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JB/T 7688.1-2008 English PDF (JB/T7688.1-2008)

JB/T 7688.1-2008 English PDF (JB/T7688.1-2008)

Regular price

$255.00

Regular price

Sale price

$255.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

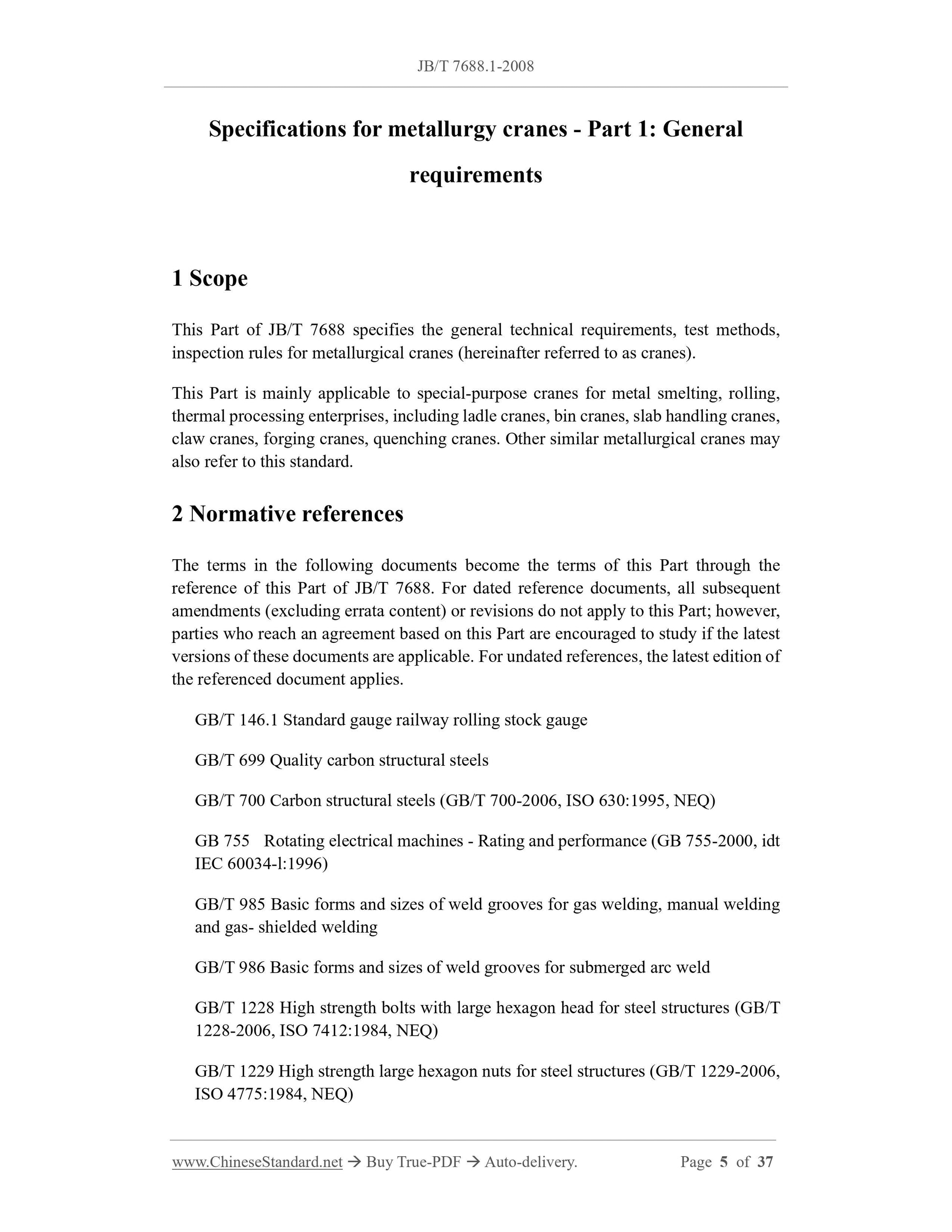

JB/T 7688.1-2008: Specifications for metallurgy cranes - Part 1: General requirements

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click JB/T 7688.1-2008 (Self-service in 1-minute)

Newer / historical versions: JB/T 7688.1-2008

Preview True-PDF

Scope

This Part of JB/T 7688 specifies the general technical requirements, test methods,inspection rules for metallurgical cranes (hereinafter referred to as cranes).

This Part is mainly applicable to special-purpose cranes for metal smelting, rolling,

thermal processing enterprises, including ladle cranes, bin cranes, slab handling cranes,

claw cranes, forging cranes, quenching cranes. Other similar metallurgical cranes may

also refer to this standard.

Basic Data

| Standard ID | JB/T 7688.1-2008 (JB/T7688.1-2008) |

| Description (Translated English) | Specifications for metallurgy cranes - Part 1: General requirements |

| Sector / Industry | Mechanical and Machinery Industry Standard (Recommended) |

| Classification of Chinese Standard | J80 |

| Classification of International Standard | 53.020.20 |

| Word Count Estimation | 21,281 |

| Date of Issue | 2008-06-04 |

| Date of Implementation | 2008-11-01 |

| Older Standard (superseded by this standard) | JB/T 7688.1-1995 |

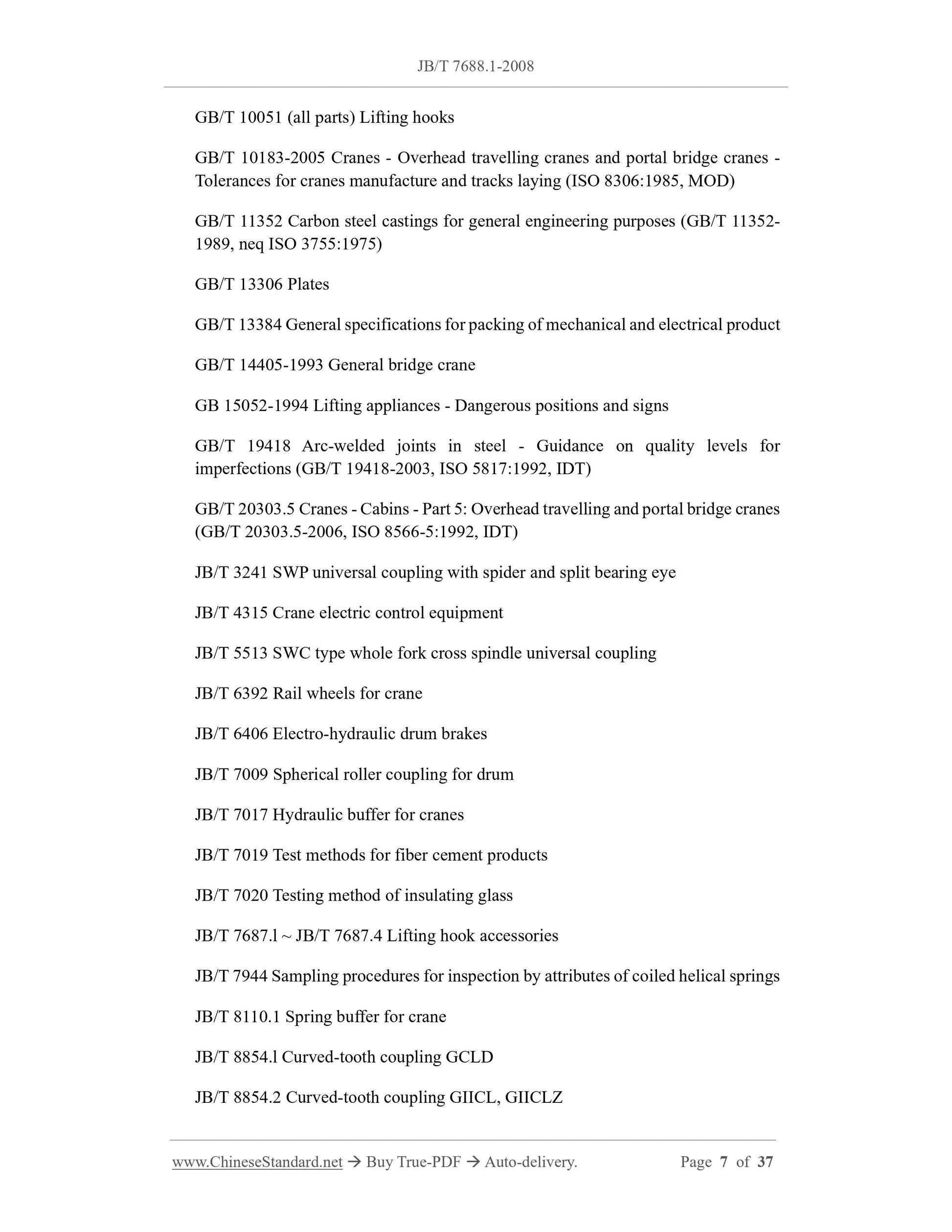

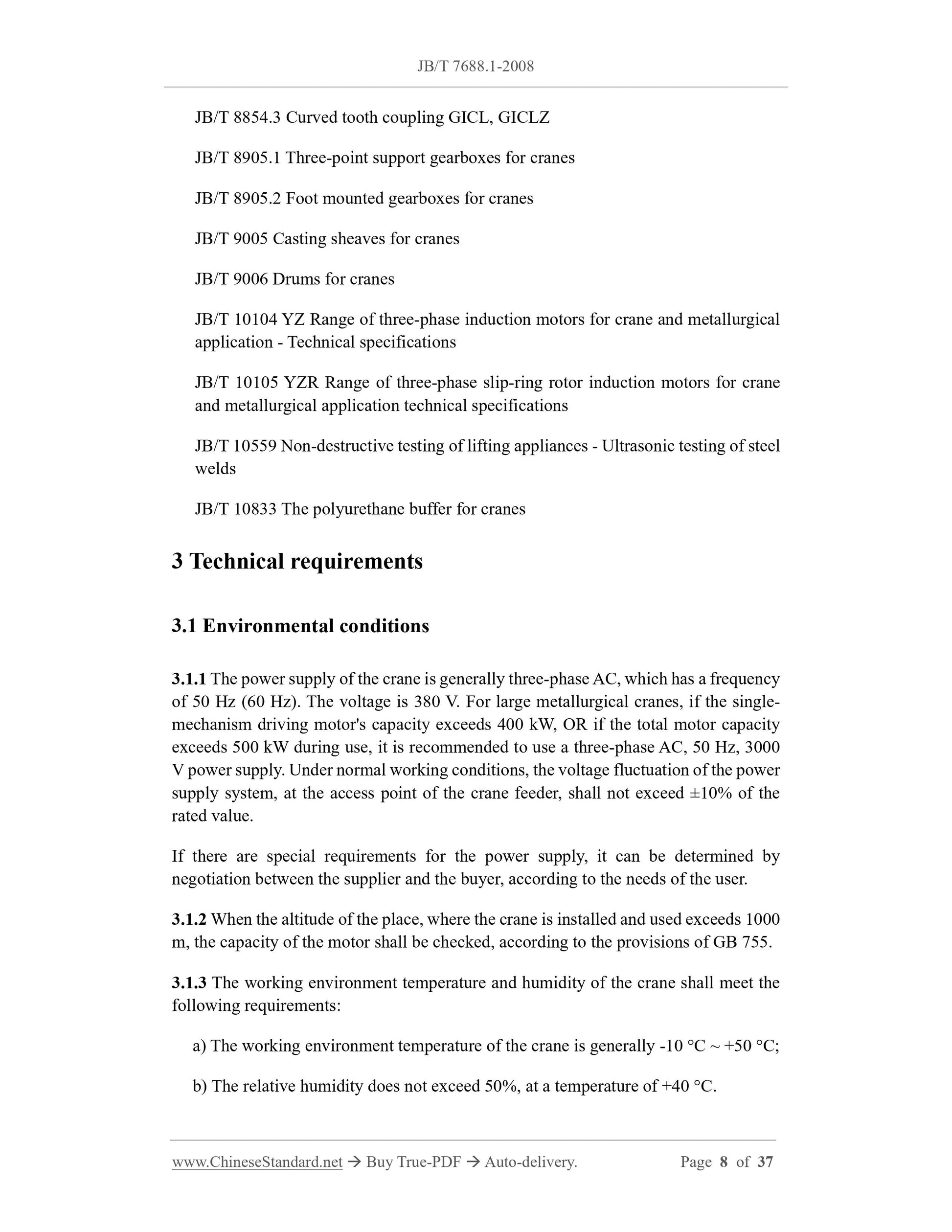

| Quoted Standard | GB/T 146..1; GB/T 699; GB/T 700; GB 755; GB/T 985; GB/T 986; GB/T 1228; GB/T 1229; GB/T 1230; GB/T 1231; GB/T 1239.2; GB/T 1239.4; GB/T 3323; GB/T 3632; GB/T 3811; GB 4208; GB/T 5905; GB/T 5972; GB/T 5973; GB/T 5974.1; GB/T 5974.2; GB/T 5975; GB/T 5976; GB 6067; GB 8918; GB/T 8923; GB/T 9286; GB/T 10051.1; GB/T 10051.2; GB/T 10051.3; GB/T 10051.4; GB/T 10051.5; GB/T 10051.6; GB/T 10051.7; GB/T 10051.8; GB/T 10051.9; GB/T 10051.10; GB/T 10051.11; GB/T 10051.12; GB/T 10051.13; GB/T 10051.14; GB/T 10051.15; GB/T 10183-2005; GB/T 11352; GB/T 13306; GB/T 13384; GB/T 14405-1993; GB 15052-1994; GB/T 19418; GB/T 20303.5; JB/T 3241; JB/T 4315; JB/T 5513; JB/T 6392; JB/T 6406; JB/T 7009; JB/T 7017; JB/T 7019; JB/T 7020; JB/T 7687.1; JB/T 7687.2; JB/T 7687.3; JB/T 7687.4; JB/T 7944; JB/T 8110.1; JB/T 8854.1; JB/T 8854.2; JB/T 8854.3; JB/T 8905.1; JB/T 8905.2; JB/T 9005; JB/T 9006; JB/T 10104; JB/T 10105; JB/T 10559; JB/T 10833 |

| Regulation (derived from) | NDRC Notice No. 38 of 2008 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the metallurgical cranes (hereinafter referred to as cranes) general technical requirements, test methods and inspection rules and so on. This section is mainly applied to metal smelting, rolling and heat processing enterprises special cranes, including casting crane, bins cranes, slab handling cranes, material rake cranes, cranes and forging quenching cranes. Other similar metallurgical cranes can also refer to the use. |

Share