1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JB/T 7361-2007 English PDF (JB/T7361-2007)

JB/T 7361-2007 English PDF (JB/T7361-2007)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

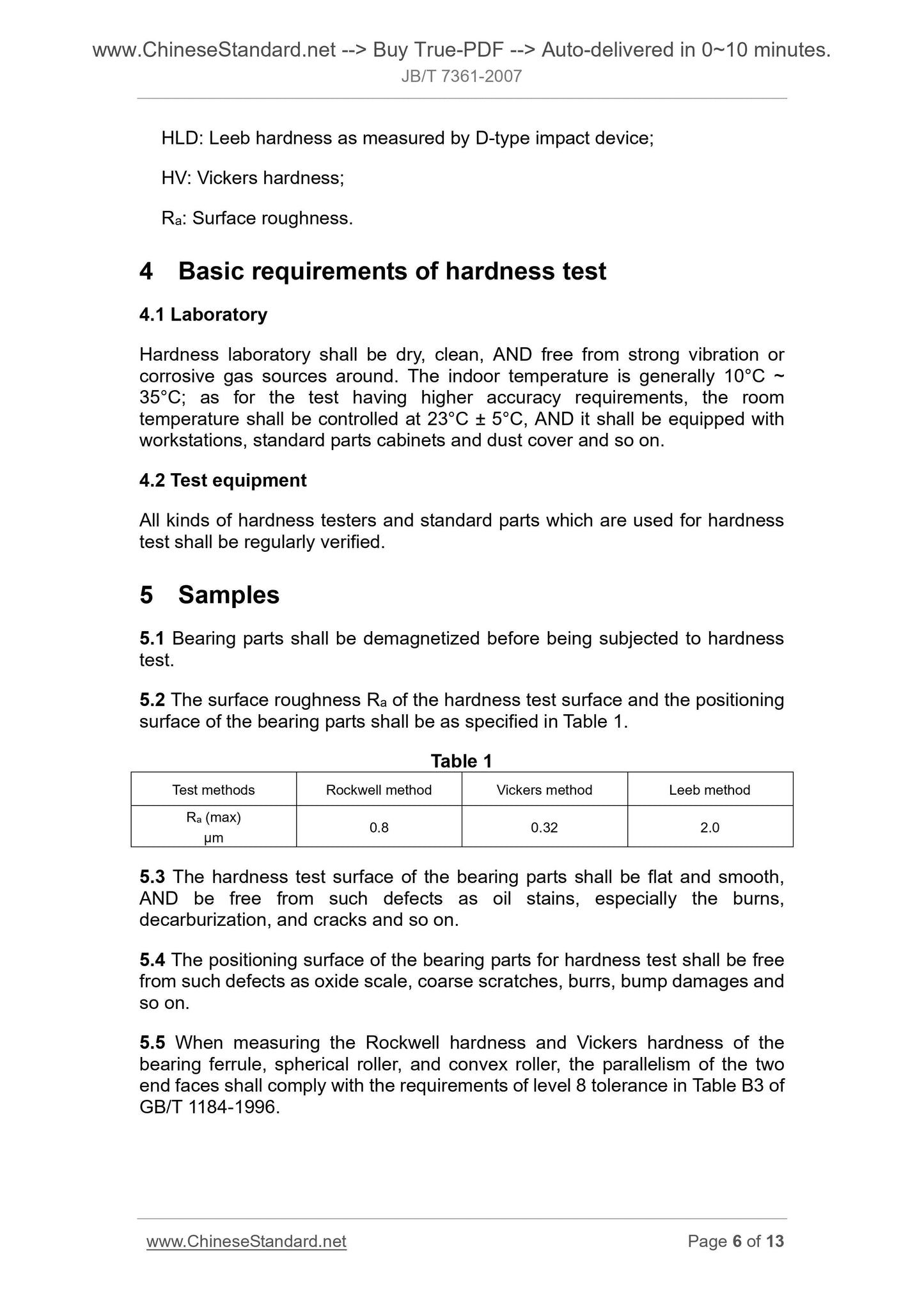

JB/T 7361-2007: Rolling bearings - Test method for hardness of parts

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click JB/T 7361-2007 (Self-service in 1-minute)

Newer / historical versions: JB/T 7361-2007

Preview True-PDF

Scope

This standard specifies the hardness test method for the steel and non-ferrousmetal bearing parts.

This standard is applicable to the hardness test of the steel bearing parts after

quenching and tempering, the finished bearing parts, and the non-ferrous

metal bearing parts.

Basic Data

| Standard ID | JB/T 7361-2007 (JB/T7361-2007) |

| Description (Translated English) | Rolling bearings - Test method for hardness of parts |

| Sector / Industry | Mechanical and Machinery Industry Standard (Recommended) |

| Classification of Chinese Standard | J11 |

| Classification of International Standard | 21.100.20 |

| Word Count Estimation | 11,148 |

| Date of Issue | 3/6/2007 |

| Date of Implementation | 2007-09-01 |

| Older Standard (superseded by this standard) | JB/T 7361-1994 |

| Quoted Standard | GB/T 230.1-2004, GB/T 1184-1996, GB/T 4340.1-1999, GB/T 17394-1998, JB/T 1255-20001 |

| Regulation (derived from) | ?National Development and Reform Commission Announcement 2007 No.16 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies test methods for hardness of steel and non-ferrous metal bearing parts. This standard applies to hardened steel bearing parts, tempering and non-ferrous metal products bearing parts and bearing parts of the hardness test. |

Share