1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JB/T 6758.2-2007 English PDF (JB/T6758.2-2007)

JB/T 6758.2-2007 English PDF (JB/T6758.2-2007)

Regular price

$90.00

Regular price

Sale price

$90.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

JB/T 6758.2-2007: Continuously transposed conductors. Part 2: Paper-insulated continuously transposed conductors of polyvinyl acetal enamelled copper wires

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click JB/T 6758.2-2007 (Self-service in 1-minute)

Newer / historical versions: JB/T 6758.2-2007

Preview True-PDF

Scope

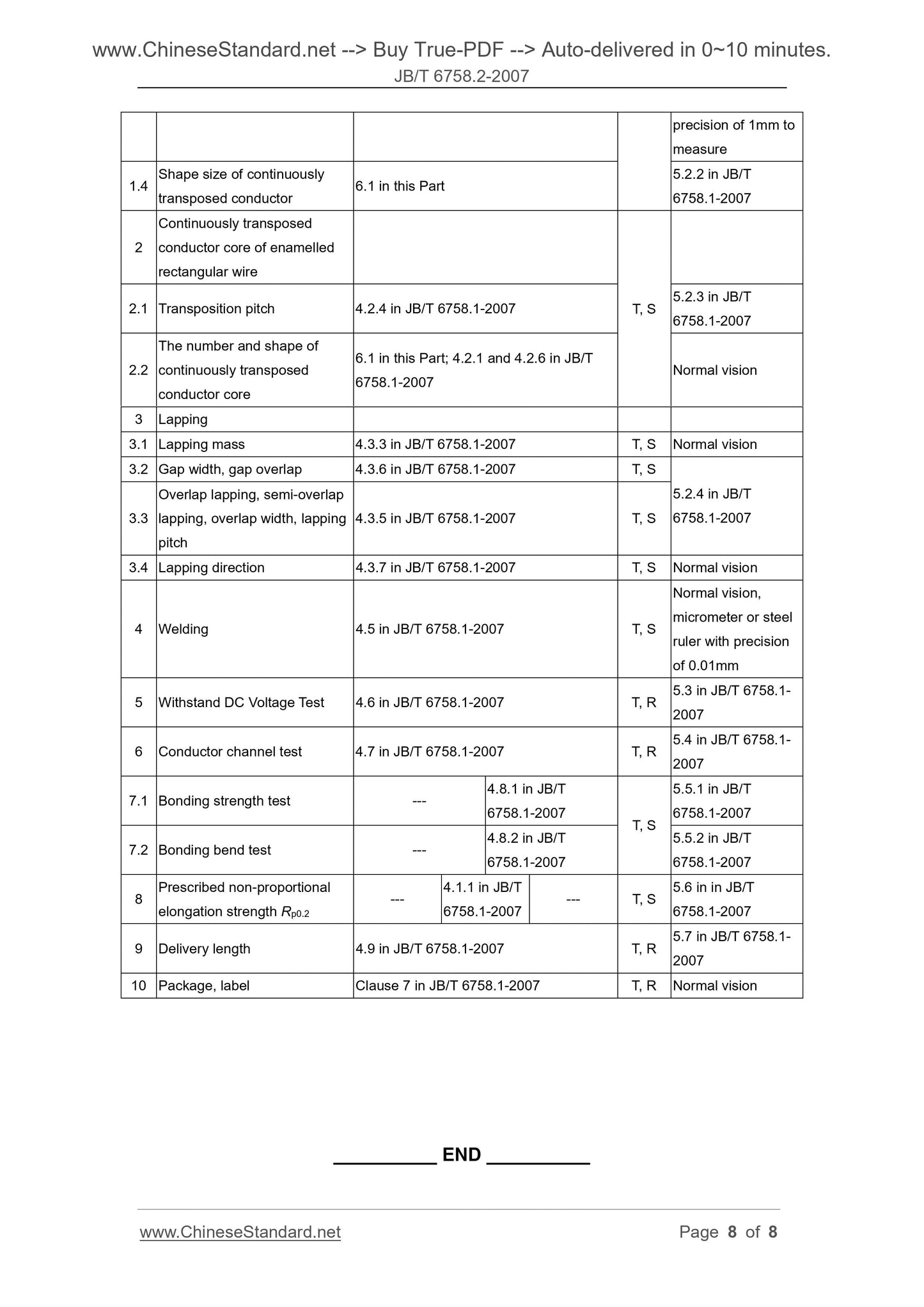

This Part of JB/T 6758 specifies the general requirements for paper-insulatedcontinuous transposed conductors of polyvinyl acetal enamelled copper wires. The

enamelled rectangular wire can be Grade-120 polyvinyl acetal enamelled rectangular

copper wire, or self-adhesive polyvinyl acetal enamelled rectangular copper wire

coated with thermosetting epoxy resin on its outside; the copper conductor can be

either conventional soft copper wire, or semi-hard copper wire. This Part shall be used

in conjunction with JB/T 6758.1.

The paper-insulated continuous transposed conductors of polyvinyl acetal enamelled

copper wires are applicable to the winding coils for oil-immersed type transformers or

electrical appliances.

Basic Data

| Standard ID | JB/T 6758.2-2007 (JB/T6758.2-2007) |

| Description (Translated English) | Continuously transposed conductors. Part 2: Paper-insulated continuously transposed conductors of polyvinyl acetal enamelled copper wires |

| Sector / Industry | Mechanical and Machinery Industry Standard (Recommended) |

| Classification of Chinese Standard | K12 |

| Classification of International Standard | 29.060.01 |

| Word Count Estimation | 6,612 |

| Date of Issue | 2007-03-06 |

| Date of Implementation | 2007-09-01 |

| Older Standard (superseded by this standard) | JB/T 6758-1993 |

| Quoted Standard | GB/T 4074.2; JB/T 6758.1-2007 |

| Regulation (derived from) | NDRC Notice No. 16 of 2007 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the paper insulation CTC acetal enamelled general requirements. Enamelled flat line can make 120 acetal enamelled copper flat wire, or on the outside coated with a thermosetting epoxy adhesive layer of self-adhesive shelf paper acetal enamelled copper flat wire, copper conductors can be both ordinary soft copper line, it can be semi-hard copper. This part should JB/T 6758. 1 together. Paper insulation acetal enameled transposed conductor for oil-immersed transformers or electrical windings. |

Share