1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JB 2293-1978 English PDF

JB 2293-1978 English PDF

Regular price

$195.00

Regular price

Sale price

$195.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

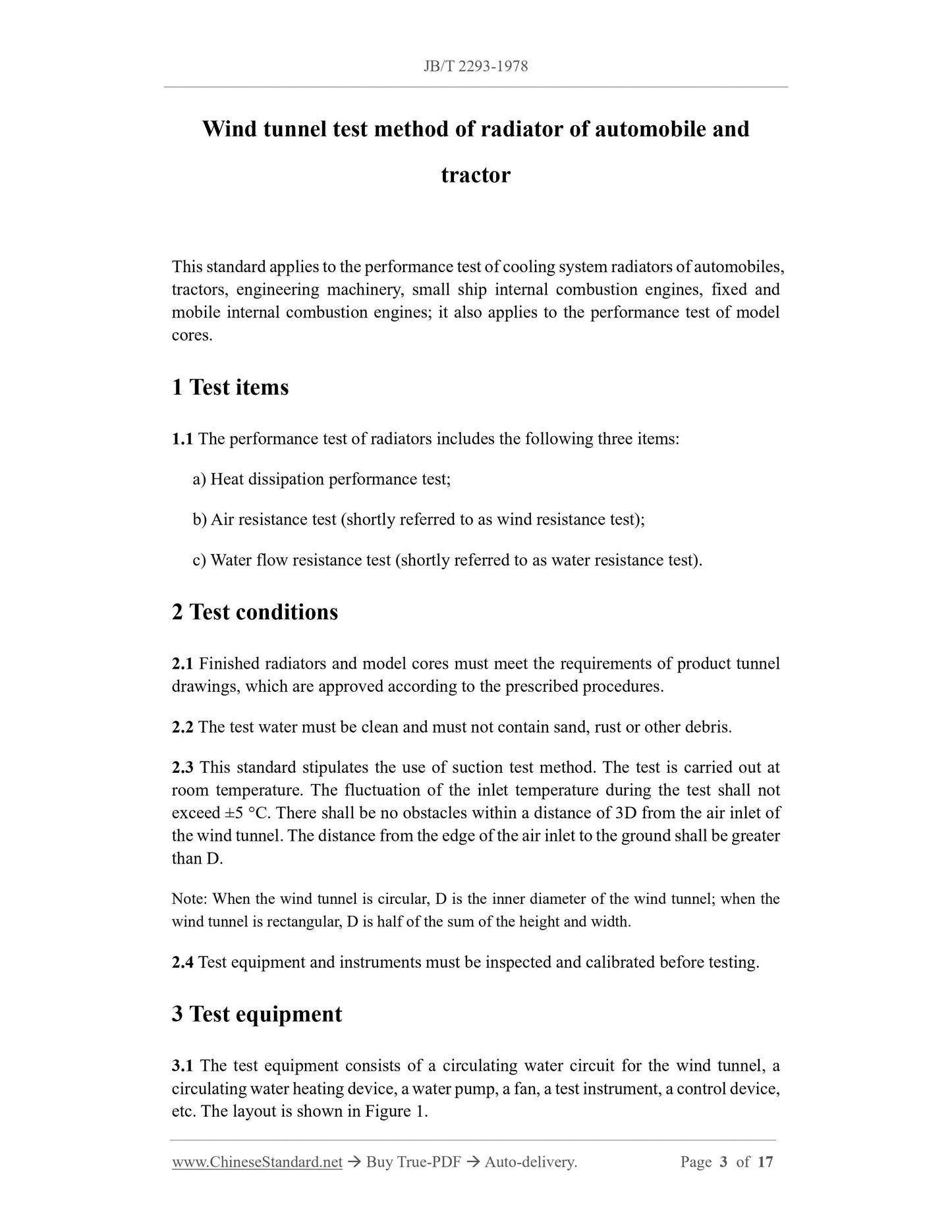

JB 2293-1978: Wind tunnel test method of radiator of automobile and tractor

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click JB 2293-1978 (Self-service in 1-minute)

Newer / historical versions: JB 2293-1978

Preview True-PDF

Scope

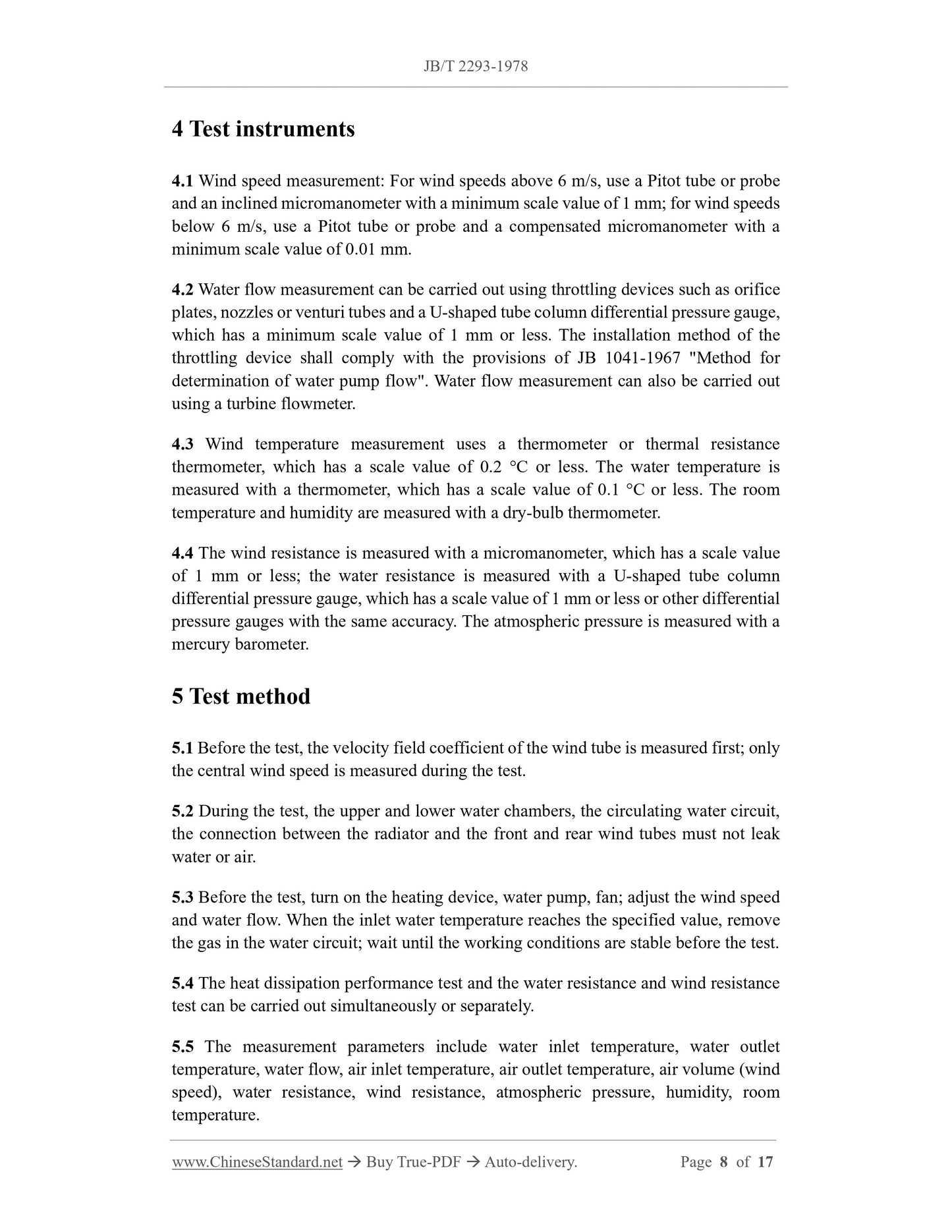

1.1 The performance test of radiators includes the following three items:a) Heat dissipation performance test;

b) Air resistance test (shortly referred to as wind resistance test);

c) Water flow resistance test (shortly referred to as water resistance test).

Basic Data

| Standard ID | JB 2293-1978 (JB2293-1978) |

| Description (Translated English) | Wind tunnel test method of radiator of automobile and tractor |

| Sector / Industry | Mechanical and Machinery Industry Standard |

Share