1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

HJ 654-2013 English PDF

HJ 654-2013 English PDF

Regular price

$430.00

Regular price

Sale price

$430.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

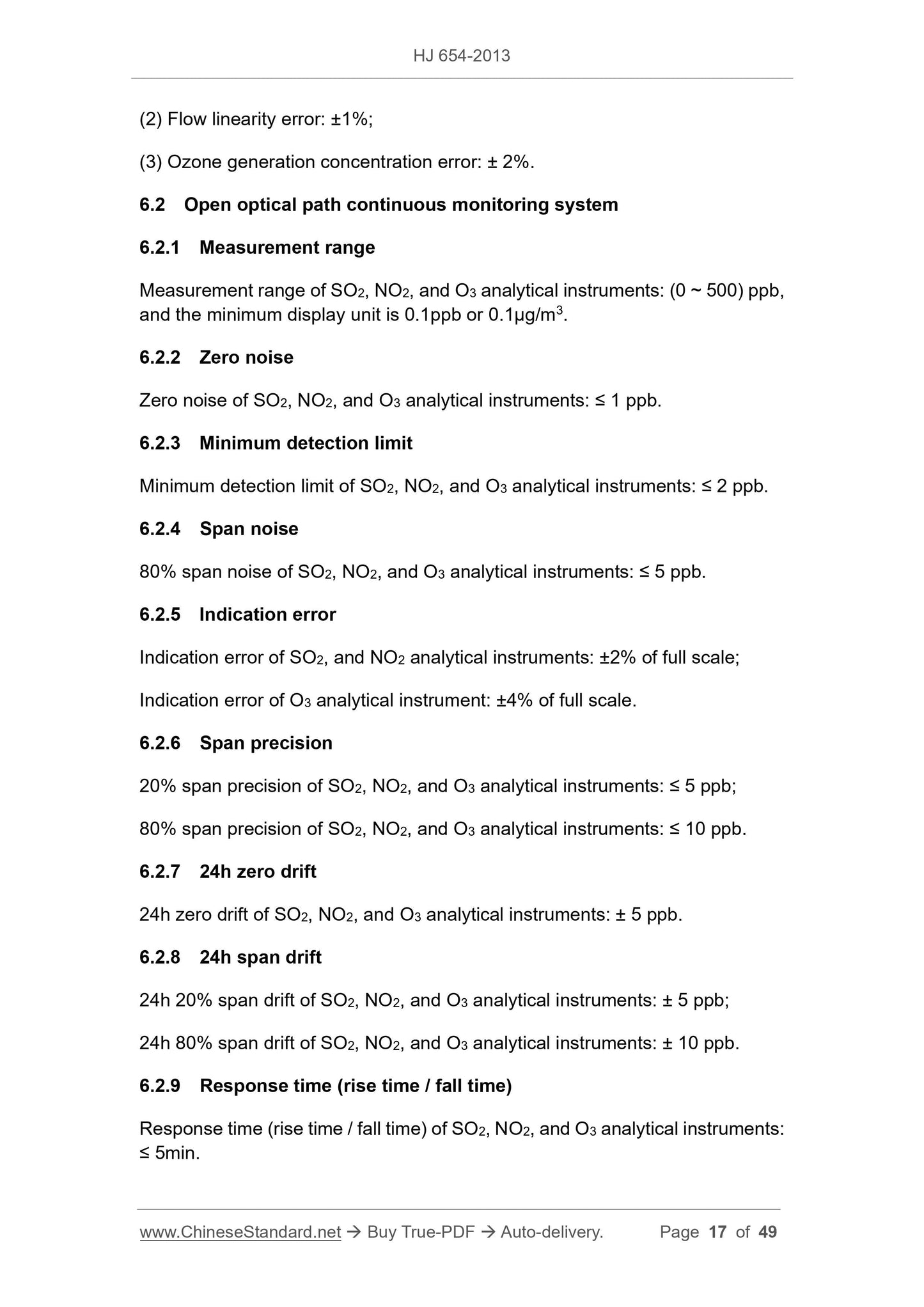

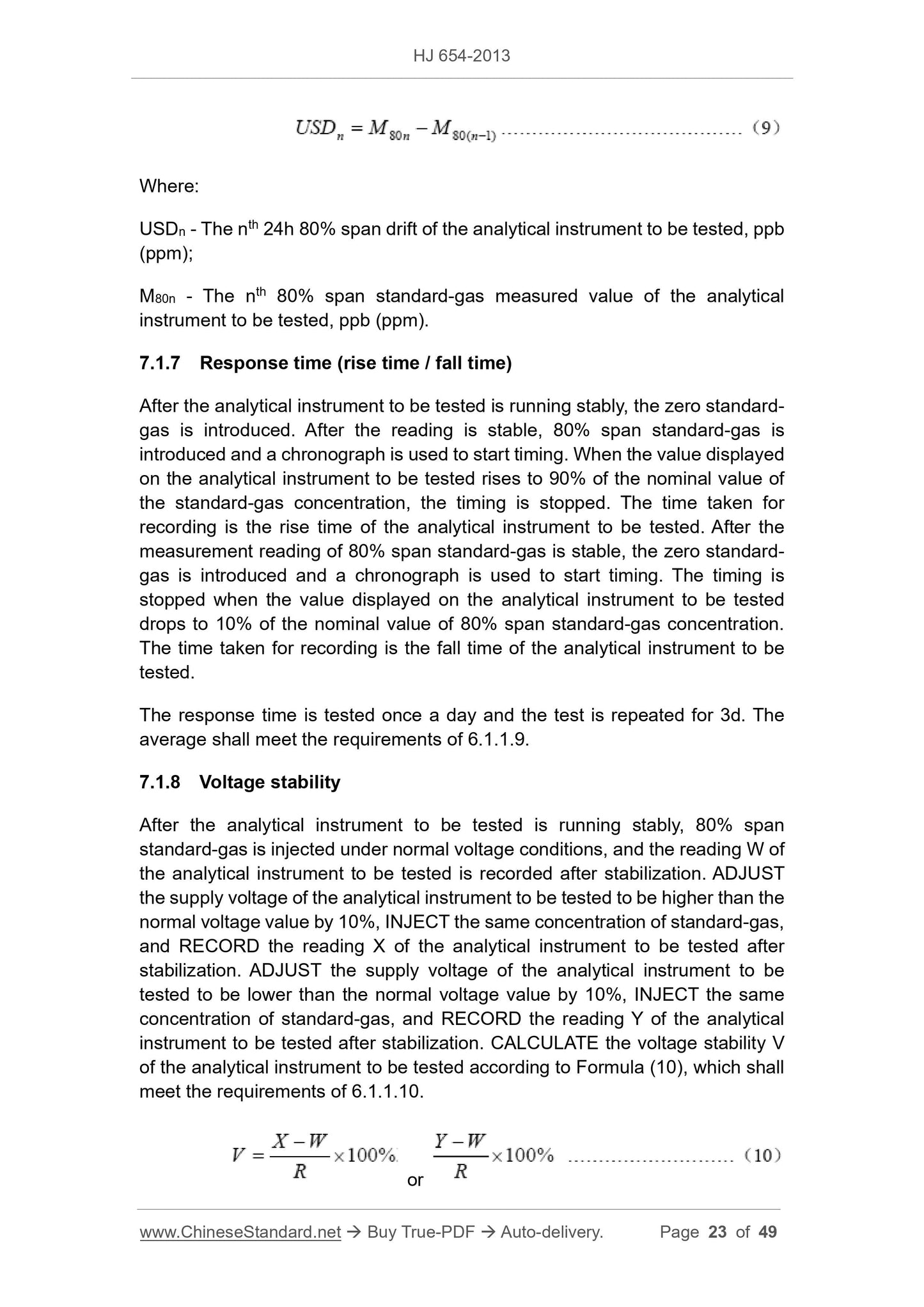

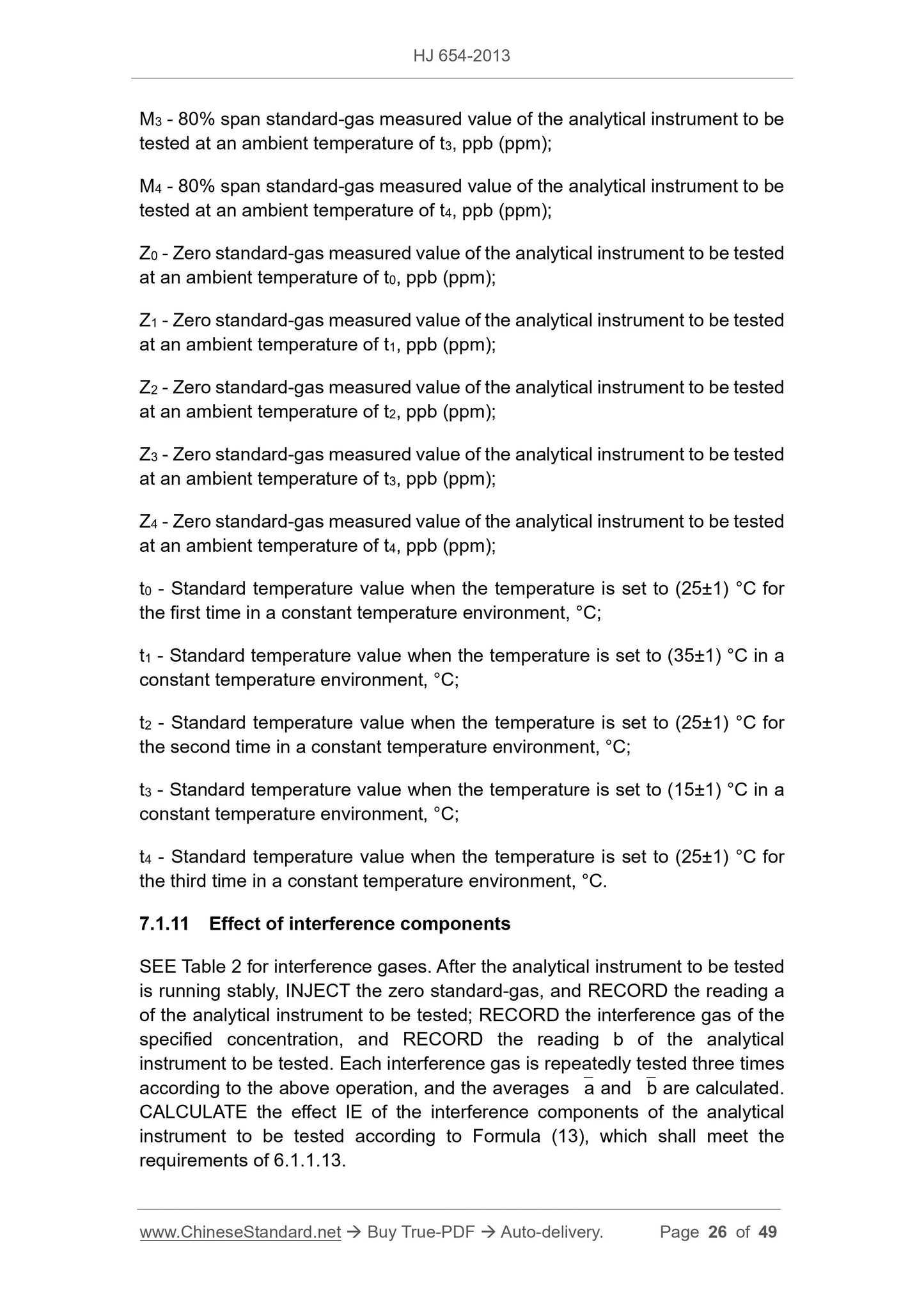

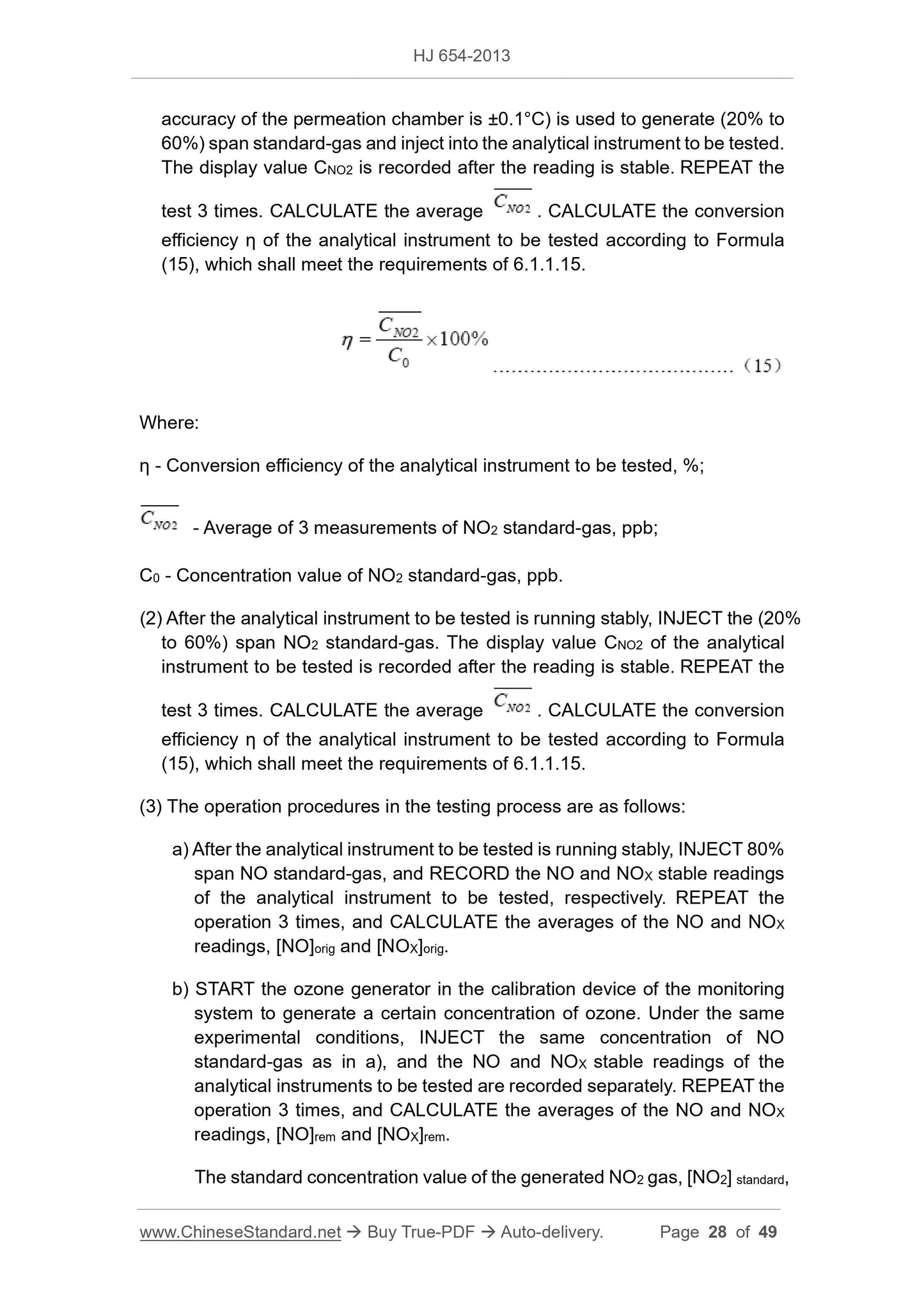

HJ 654-2013: Specifications and test procedures for ambient air quality continuous automated monitoring system for SO2, NO2, O3 and CO

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click HJ 654-2013 (Self-service in 1-minute)

Newer / historical versions: HJ 654-2013

Preview True-PDF

Scope

This Standard specifies the composition, specifications, test indicators and testprocedures for ambient air quality continuous automated monitoring system for

SO2, NO2, O3 and CO.

This Standard is applicable to the design, production and testing of ambient air

quality continuous automated monitoring system for SO2, NO2, O3 and CO.

Basic Data

| Standard ID | HJ 654-2013 (HJ654-2013) |

| Description (Translated English) | Specifications and test procedures for ambient air quality continuous automated monitoring system for SO2, NO2, O3 and CO |

| Sector / Industry | Environmental Protection Industry Standard |

| Classification of Chinese Standard | Z15 |

| Classification of International Standard | 13.040.20 |

| Word Count Estimation | 32,345 |

| Quoted Standard | GB 3095-2012; GB 4793.1 |

| Regulation (derived from) | Department of Environmental Protection Notice No. 48 of 2013; |

| Issuing agency(ies) | Ministry of Ecology and Environment |

| Summary | This standard specifies: structure, technical requirements, performance metrics and test methods ambient air gaseous pollutants (SO2, NO2, O3, CO) continuous automatic monitoring system components. This standard applies to the ambient air of gaseous pollu |

Share