1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

HJ 212-2017 English PDF

HJ 212-2017 English PDF

Regular price

$495.00

Regular price

Sale price

$495.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

HJ 212-2017: Data transmission standard for online monitoring systems of pollutant

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click HJ 212-2017 (Self-service in 1-minute)

Newer / historical versions: HJ 212-2017

Preview True-PDF

Scope

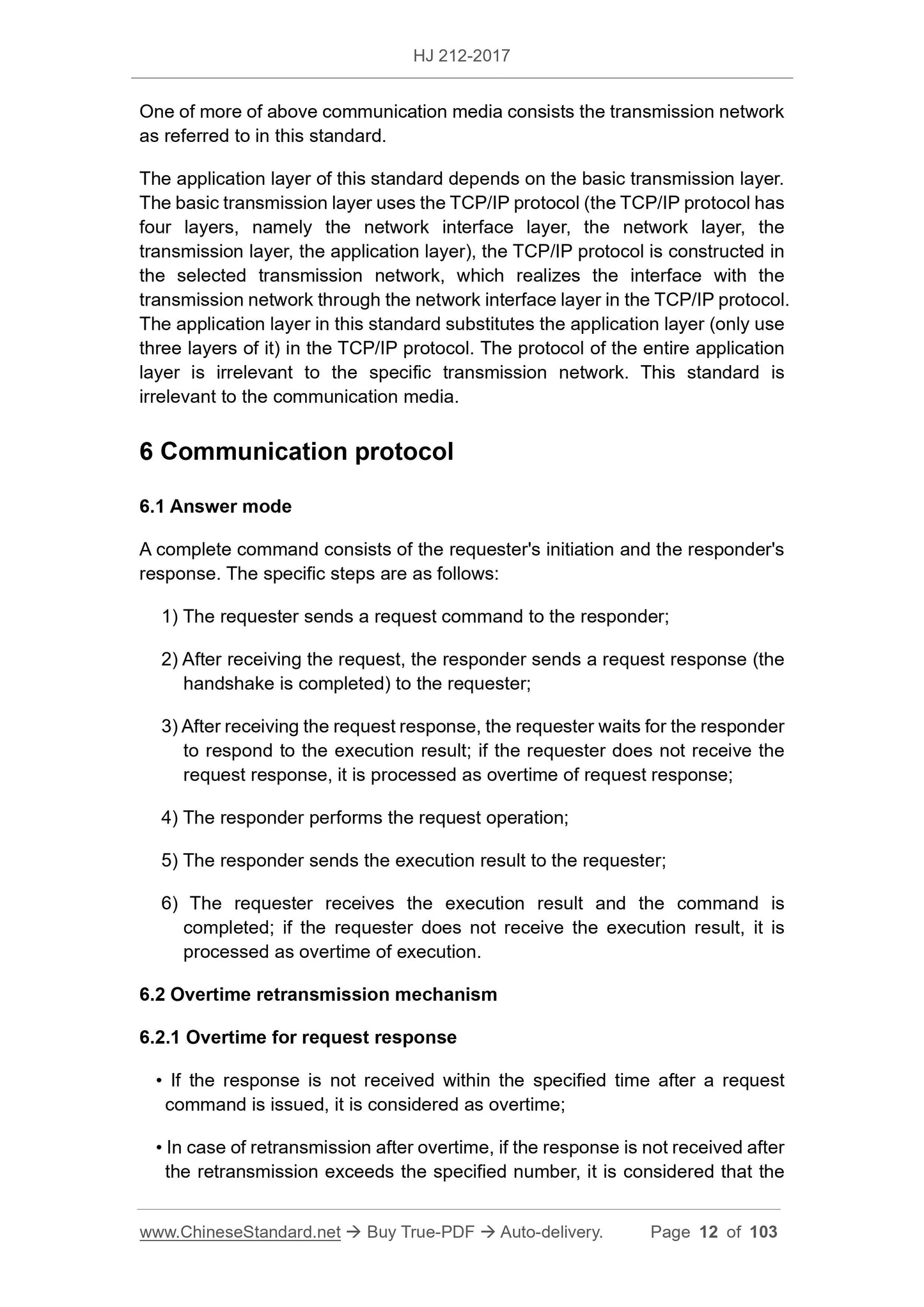

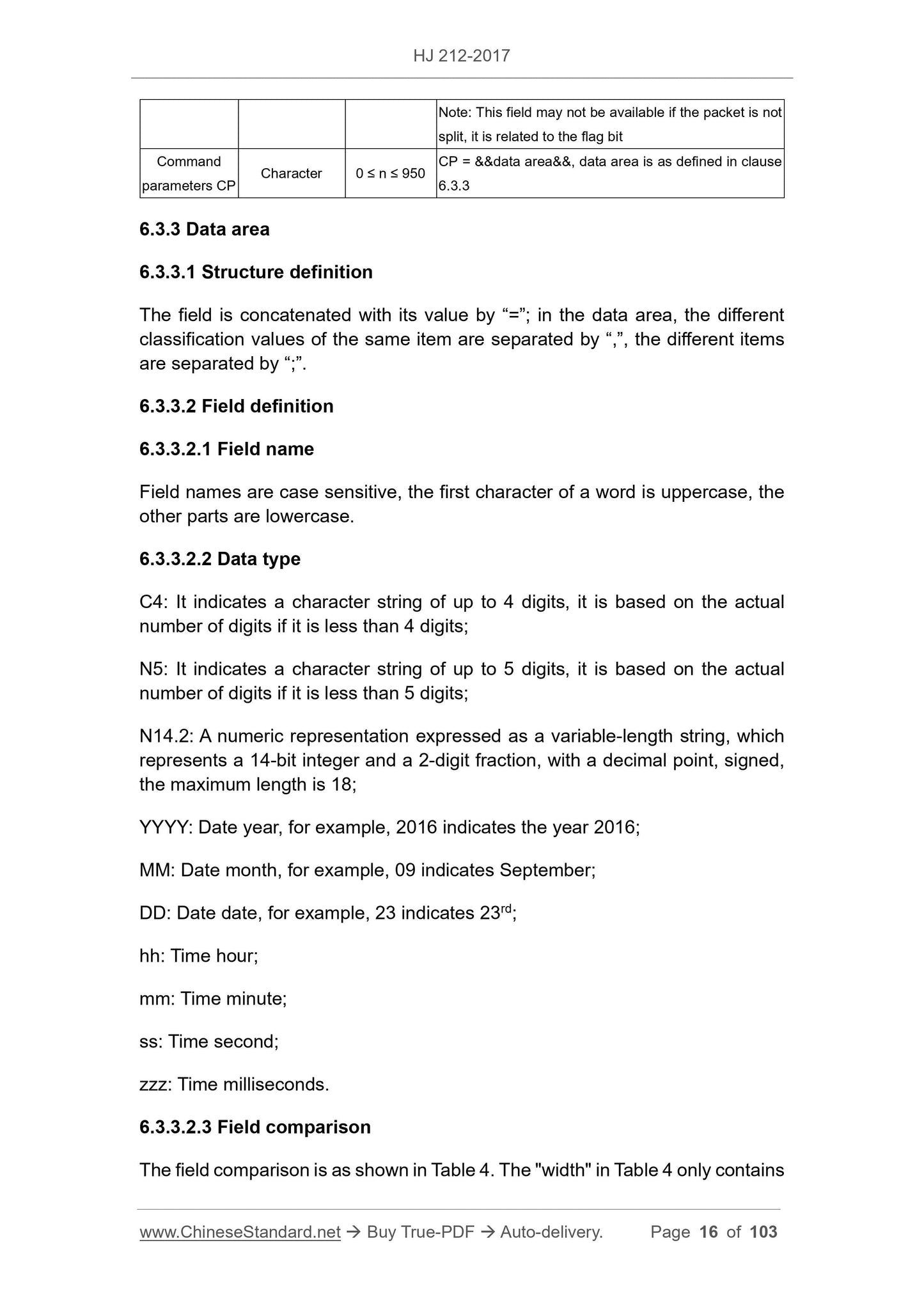

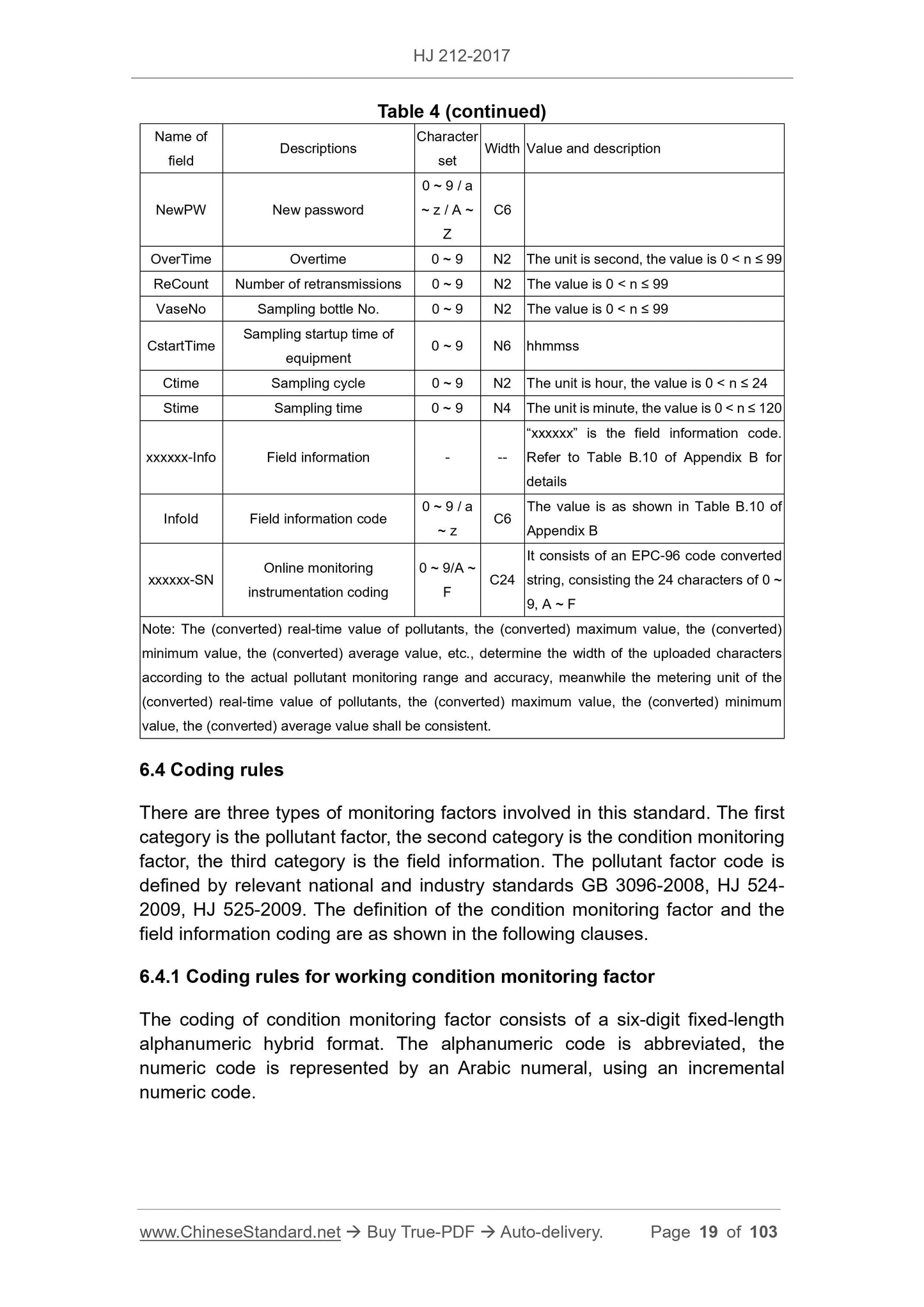

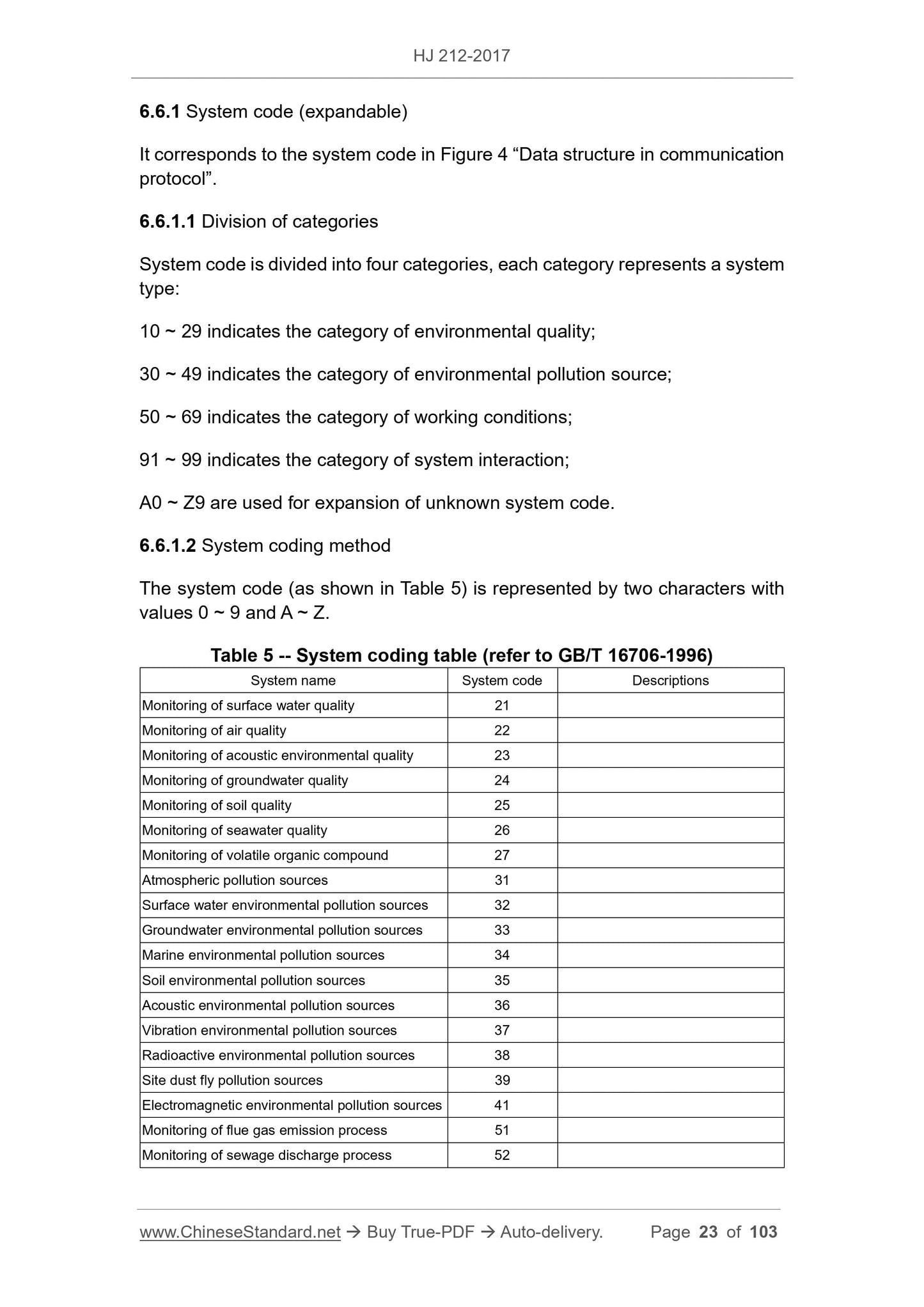

This standard applies to the data transmission between the online monitoringsystem of pollutants, the automatic monitoring system of the pollutant discharge

process (working conditions), and the monitoring center. It specifies the

transmission process as well as the format of parameter commands, interactive

commands, data commands, control commands; gives the definition of code.

This standard allows for expansion, but the expansion of content shall not

conflict with the control commands used or retained in this standard.

This standard also specifies the data transmission format between the online

monitoring instrumentation and the data acquisition transmitter, meanwhile

gives the definition of code.

Basic Data

| Standard ID | HJ 212-2017 (HJ212-2017) |

| Description (Translated English) | Data transmission standard for online monitoring systems of pollutant |

| Sector / Industry | Environmental Protection Industry Standard |

| Classification of Chinese Standard | Z10 |

| Classification of International Standard | 13.020.40 |

| Word Count Estimation | 62,611 |

| Date of Issue | 2017-04-24 |

| Date of Implementation | 2017-05-01 |

| Older Standard (superseded by this standard) | HJ 212-2005 |

| Quoted Standard | GB 3096-2008; GB/T 16706-1996; GB/T 19582-2008; HJ/T 75-2007; HJ/T 76-2007; HJ 524-2009; HJ 525-2009 |

| Regulation (derived from) | Ministry of Environmental Protection Notice No. 15 of 2017 |

| Issuing agency(ies) | Ministry of Ecology and Environment |

| Summary | This standard applies to the data transmission between the pollutant on-line monitoring (monitoring) system, the pollutant discharge process (condition) automatic monitoring system and the monitoring center, and specifies the transmission process and parameter commands, interactive commands, data commands and control commands. The format of the code, given the code definition, this standard allows extensions, but the extension of the content must not conflict with the control commands used or retained in this standard. This standard also stipulates the format of data transmission between on-line monitoring (monitoring) instruments and data acquisition and transmission devices, and gives code definitions. |

Share