1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

HG/T 5871-2021 English PDF (HG/T5871-2021)

HG/T 5871-2021 English PDF (HG/T5871-2021)

Regular price

$230.00

Regular price

Sale price

$230.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

HG/T 5871-2021: Technical specification for green-design product assessment - Polyethylene terephthalate resin

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click HG/T 5871-2021 (Self-service in 1-minute)

Newer / historical versions: HG/T 5871-2021

Preview True-PDF

Scope

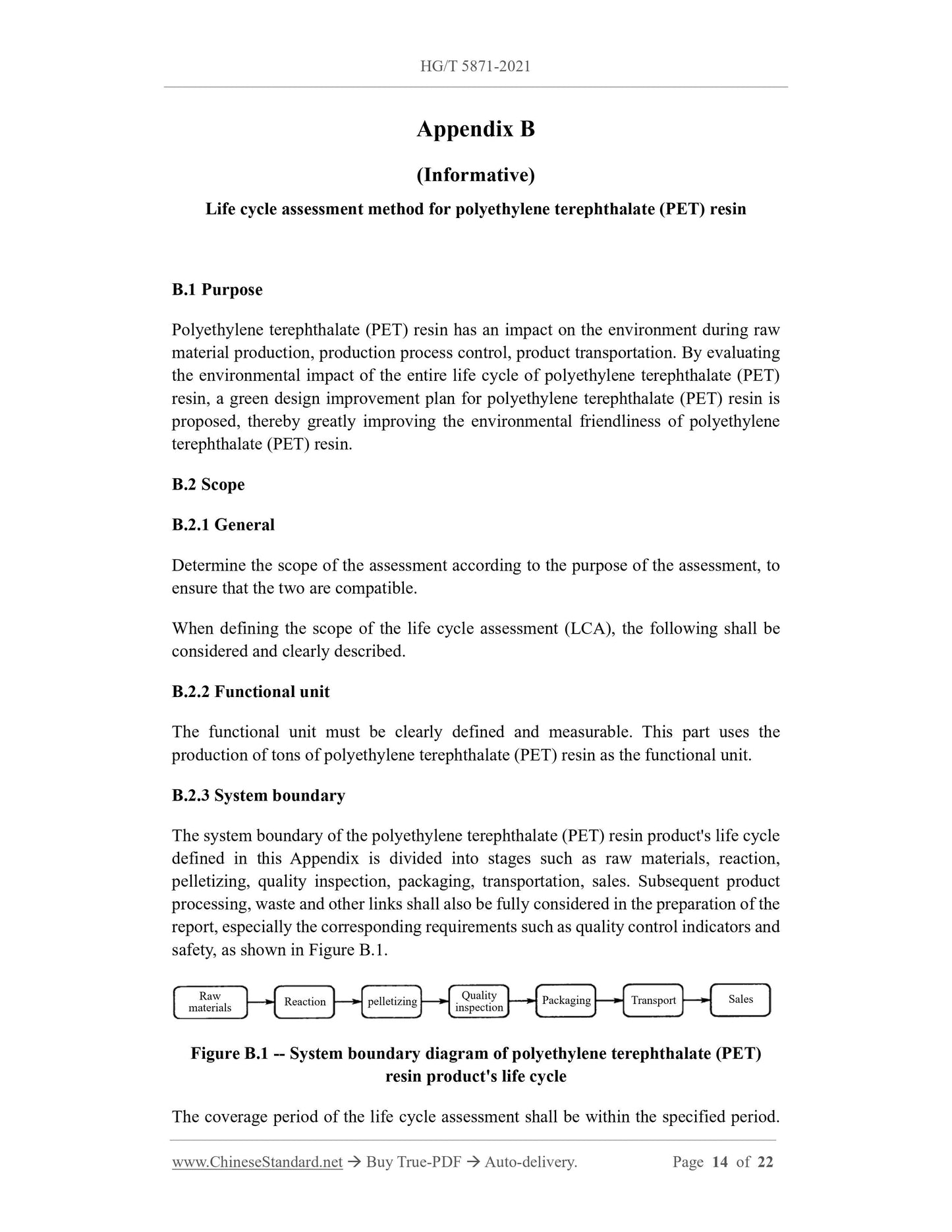

This standard specifies the terms and definitions, assessment principles and methods,assessment requirements, product life cycle assessment report preparation methods for

polyethylene terephthalate (PET) resin green design products.

This standard applies to the assessment of polyethylene terephthalate (PET) resin green

design products, which are produced by the direct esterification process.

Basic Data

| Standard ID | HG/T 5871-2021 (HG/T5871-2021) |

| Description (Translated English) | Technical specification for green-design product assessment - Polyethylene terephthalate resin |

| Sector / Industry | Chemical Industry Standard (Recommended) |

| Classification of Chinese Standard | Z04 |

| Word Count Estimation | 16,199 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

Share