1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

HG/T 4304-2012 English PDF (HG/T4304-2012)

HG/T 4304-2012 English PDF (HG/T4304-2012)

Regular price

$120.00

Regular price

Sale price

$120.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

HG/T 4304-2012: Anti-Corrosion technical conditions for equipment lined with polyolefine (PO)

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click HG/T 4304-2012 (Self-service in 1-minute)

Newer / historical versions: HG/T 4304-2012

Preview True-PDF

Scope

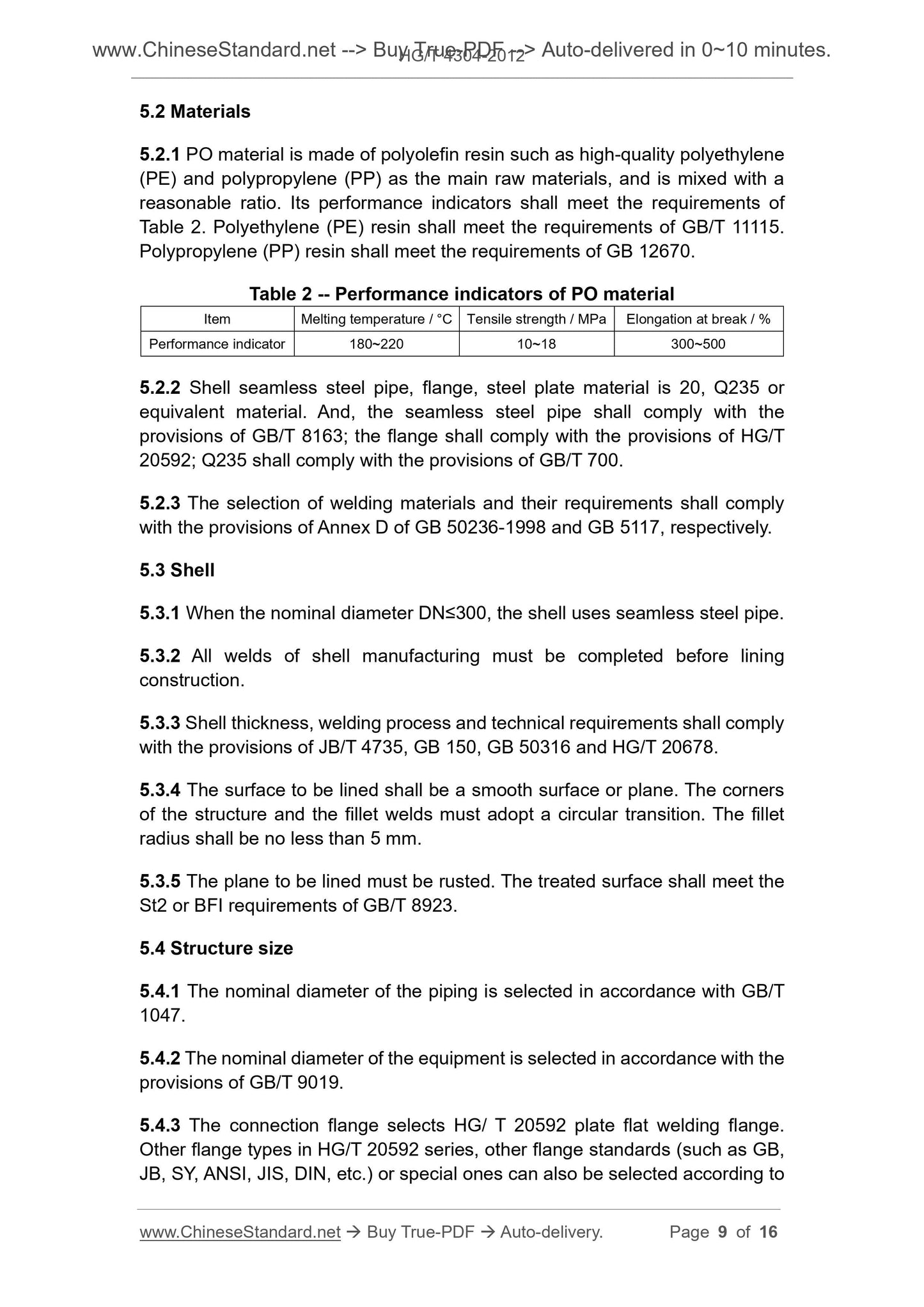

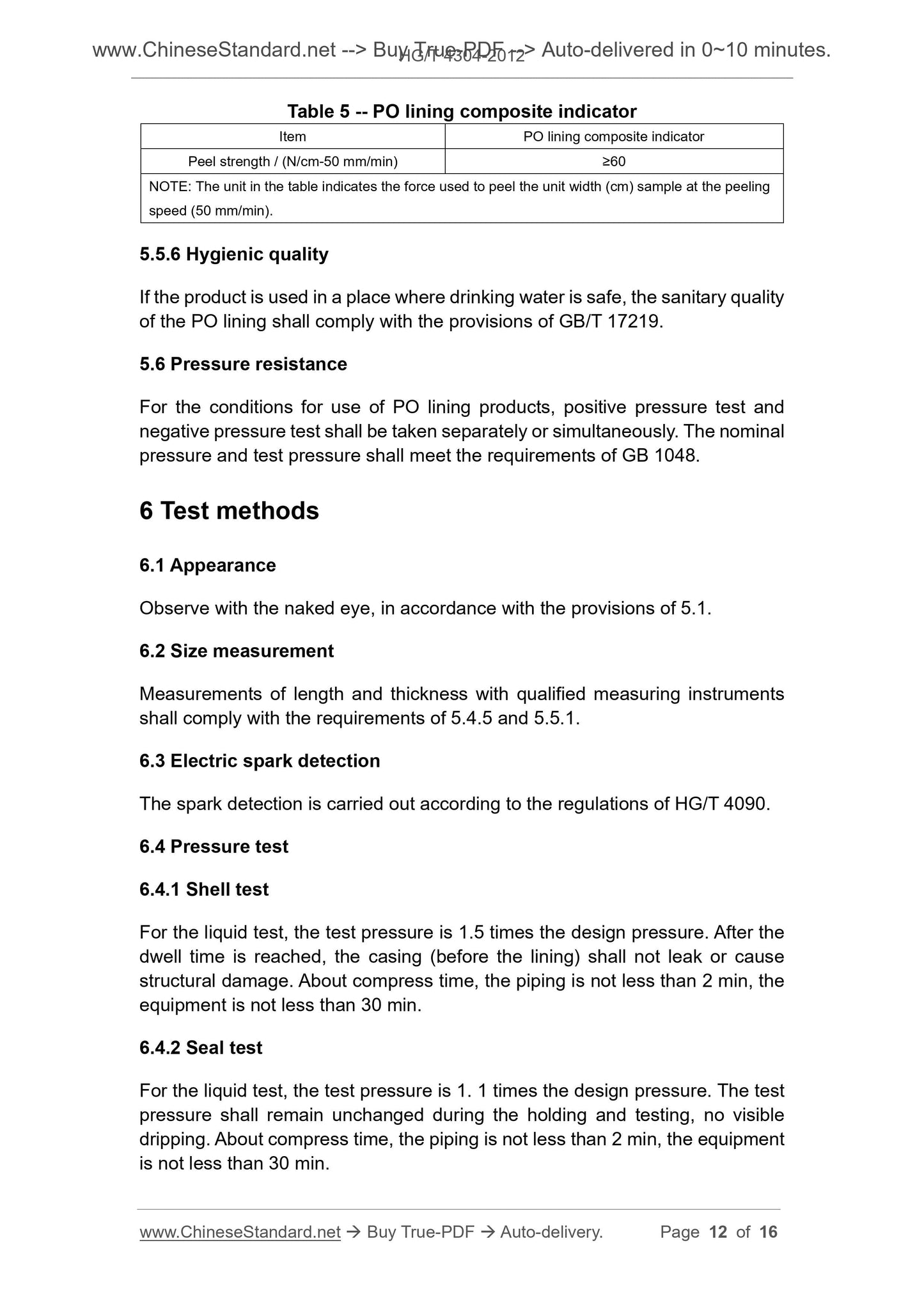

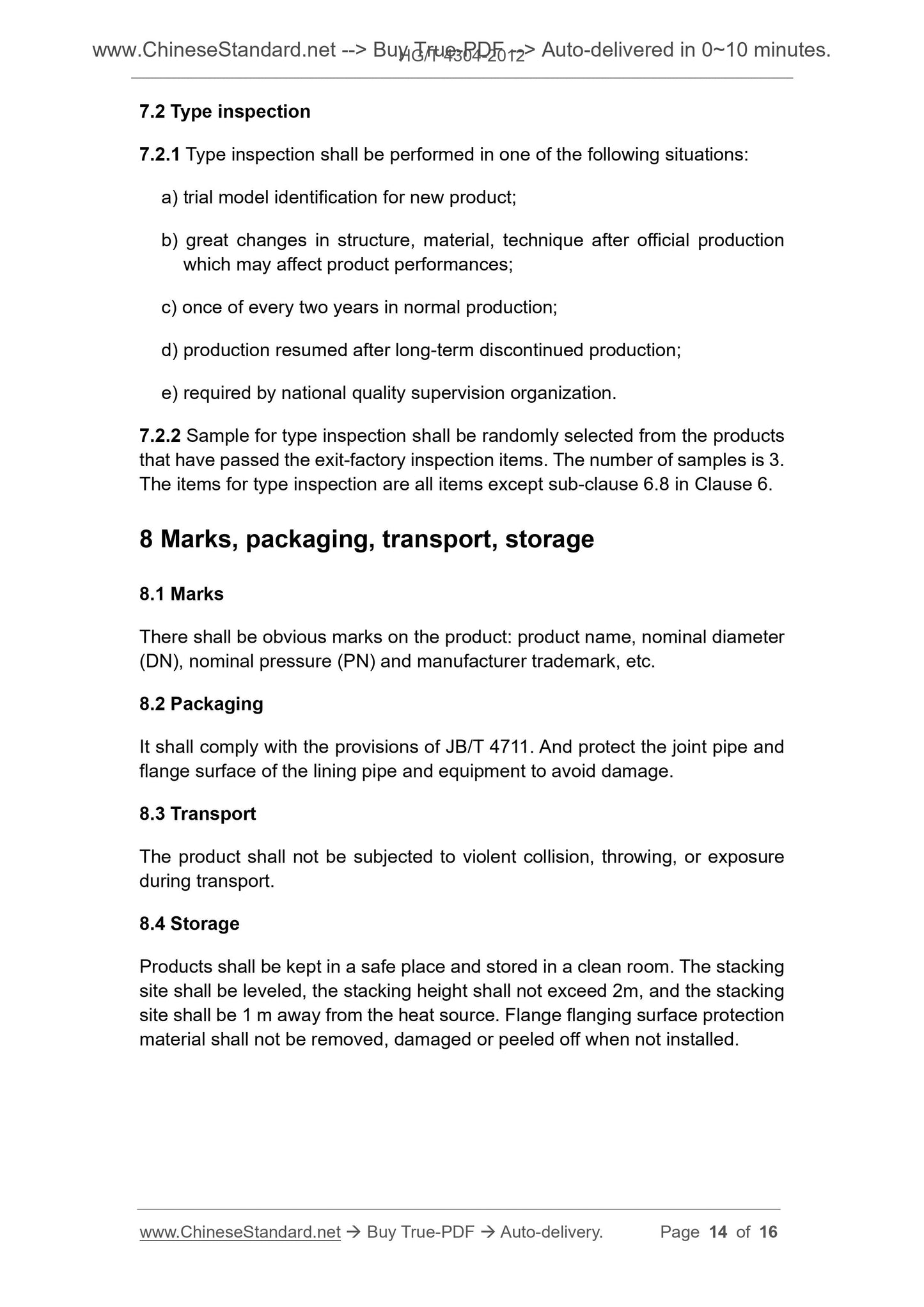

This Standard specifies the terms and definitions, classification and applicationconditions, technical requirements, test methods as well as inspection rules and

marks, packaging, transport, storage of anti-corrosion polyolefin (Polyolefine,

hereinafter referred to as PO) plastic-lined steel piping and equipment.

This Standard is applicable to PO rotational casting lining steel (hereinafter

referred to as C.S) piping and equipment of which the nominal pressure PN is

0.098MPa ~ 1.6MPa, temperature for use is 20°C ~ 100°C, nominal diameter

is DN25mm ~ DN8000mm.

Basic Data

| Standard ID | HG/T 4304-2012 (HG/T4304-2012) |

| Description (Translated English) | Anti-Corrosion technical conditions for equipment lined with polyolefine (PO) |

| Sector / Industry | Chemical Industry Standard (Recommended) |

| Classification of Chinese Standard | J16 |

| Classification of International Standard | 83.140.30 |

| Word Count Estimation | 12,178 |

| Quoted Standard | GB 150; GB/T 700; GB/T 1047; GB/T 1048; GB/T 1804; GB/T 5117; GB/T 7122; GB/T 8163; GB/T 8923; GB/T 9019; GB/T 11115; GB/T 12670; GB/T 17219; GB 50236-1998; GB 50316; HG/T 4088; HG/T 4090; HG/T 4091-2009; HG/T 4092-2009; HG/T 20592; HG/T 20678; JB/T 4711; |

| Regulation (derived from) | Ministry of Industry and Information Technology Bulletin 2012 No. 70; industry standard filing Notice 2013 No. 2 (No. 158 overall) |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the corrosion polyolefin (Polyolefine, hereinafter referred to as PO) plastic-lined steel piping and equipment terms and definitions, classification and applicable conditions, technical requirements, test methods and inspection rul |

Share