1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

HG/T 20628-2009 English PDF (HG/T20628-2009)

HG/T 20628-2009 English PDF (HG/T20628-2009)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

HG/T 20628-2009: PTFE envelope gaskets for use with steel pipe flanges (Class designated)

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click HG/T 20628-2009 (Self-service in 1-minute)

Newer / historical versions: HG/T 20628-2009

Preview True-PDF

Scope

This standard specifies the type, dimension, technical requirements and marking ofPTFE envelope gaskets for use with steel pipe flanges (Class designated).

This standard is applicable to the PTFE envelope gaskets for use with raised-face steel

pipe flanges that the nominal pressures are Class150 (PN20) and Class300 (PN50) and the

working temperature is less than or equal to 150℃ (specified in HG/T 20615).

Note. As for the use of the gaskets in which contain the material of asbestos, it shall meet the requirements of the relevant

laws and regulations. If the aforesaid gaskets are used, the protective measures shall be adopted to prevent man from damaging.

Basic Data

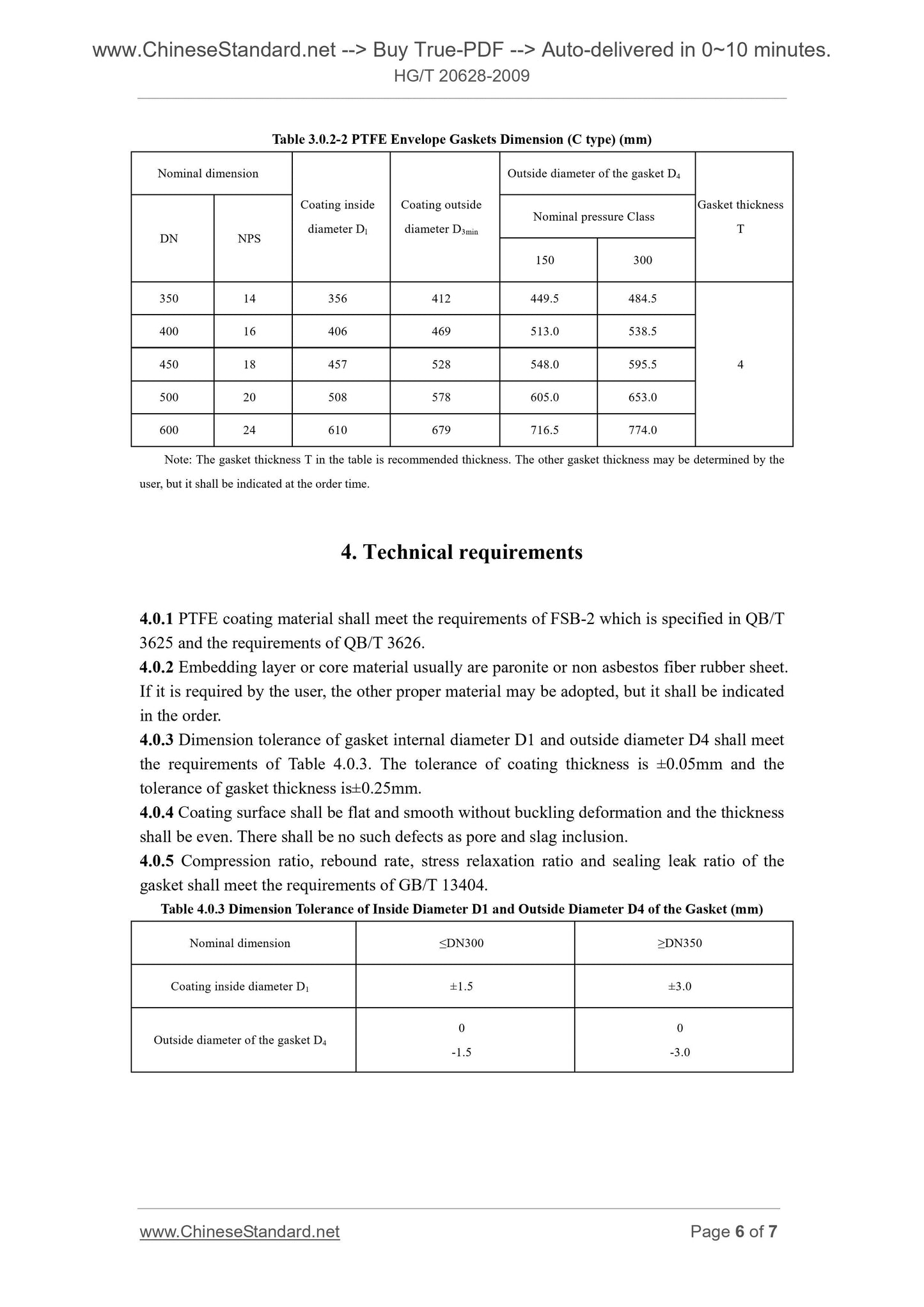

| Standard ID | HG/T 20628-2009 (HG/T20628-2009) |

| Description (Translated English) | PTFE envelope gaskets for use with steel pipe flanges (Class designated) |

| Sector / Industry | Chemical Industry Standard (Recommended) |

| Classification of Chinese Standard | J15 |

| Classification of International Standard | 23.040.60 |

| Word Count Estimation | 18,179 |

| Date of Issue | 2009-02-05 |

| Date of Implementation | 2009-07-01 |

| Older Standard (superseded by this standard) | HG 20628-1997 |

| Quoted Standard | GB/T 3985; GB/T 13404; HG/T 20615; HG/T 20635; QB/T 3625; QB/T 3626 |

| Regulation (derived from) | Engineering [ 2009 ] No. 27 |

| Issuing agency(ies) | Ministry of Industry and Information Technology |

| Summary | This standard specifies the steel pipe flanges (Class Series) with a Teflon -coated gasket type, size and technical requirements and marking. This standard applies to HG/T 20615 specified nominal Class150 (PN20) and Class300 (PN50), working temperature �� 150��C projecting surface of steel pipe flanges with PTFE envelope gaskets. |

Share