1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 9444-2019 English PDF (GB/T9444-2019)

GB/T 9444-2019 English PDF (GB/T9444-2019)

Regular price

$555.00

Regular price

Sale price

$555.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 9444-2019: Steel and iron castings - Magnetic particle inspection

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 9444-2019 (Self-service in 1-minute)

Newer / historical versions: GB/T 9444-2019

Preview True-PDF

Scope

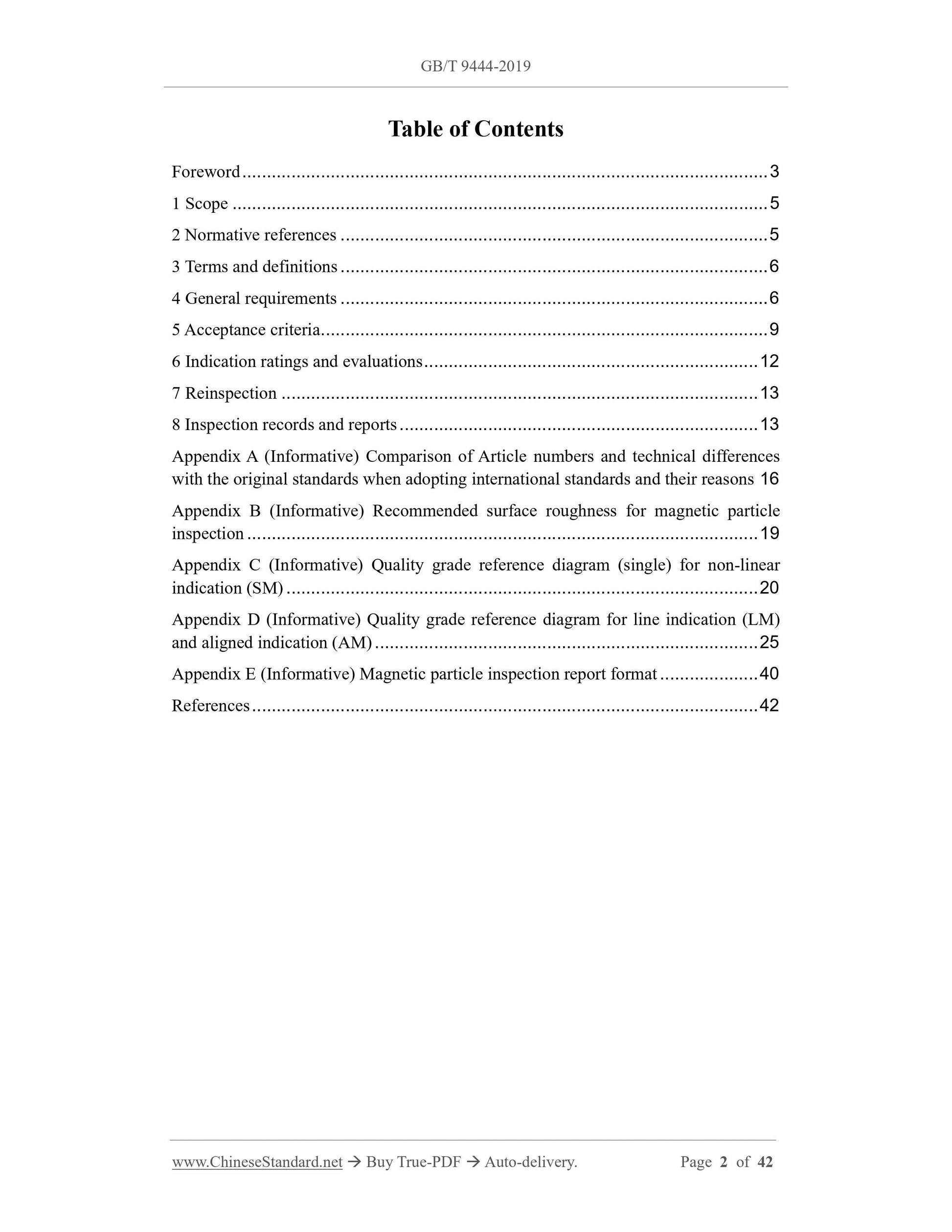

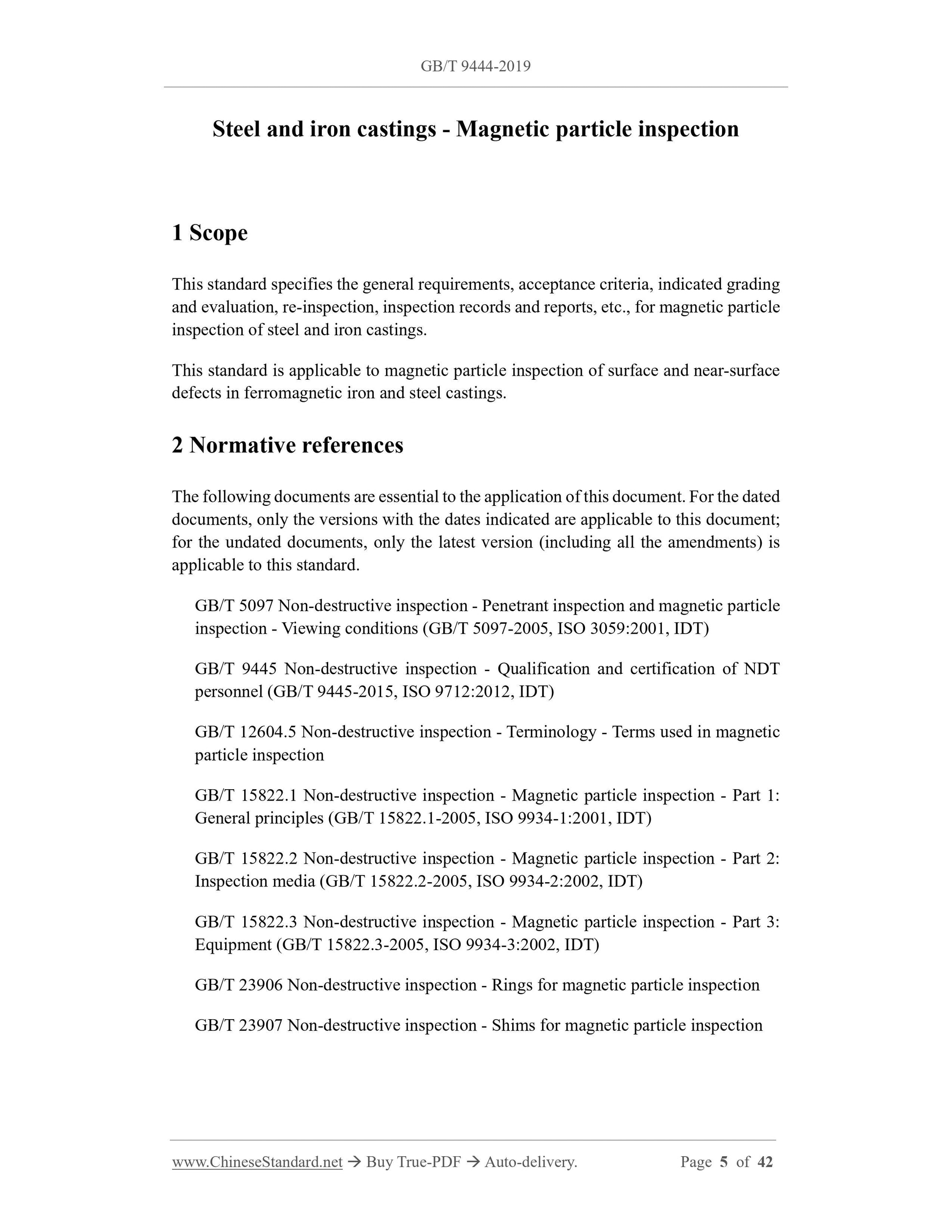

This standard specifies the general requirements, acceptance criteria, indicated gradingand evaluation, re-inspection, inspection records and reports, etc., for magnetic particle

inspection of steel and iron castings.

Basic Data

| Standard ID | GB/T 9444-2019 (GB/T9444-2019) |

| Description (Translated English) | Steel and iron castings - Magnetic particle inspection |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | J31 |

| Classification of International Standard | 77.040.20 |

| Word Count Estimation | 38,380 |

| Date of Issue | 2019-08-30 |

| Date of Implementation | 2020-03-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share