1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 90.1-2023 English PDF (GB/T90.1-2023)

GB/T 90.1-2023 English PDF (GB/T90.1-2023)

Regular price

$260.00

Regular price

Sale price

$260.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 90.1-2023: Fasteners - Acceptance inspection

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 90.1-2023 (Self-service in 1-minute)

Newer / historical versions: GB/T 90.1-2023

Preview True-PDF

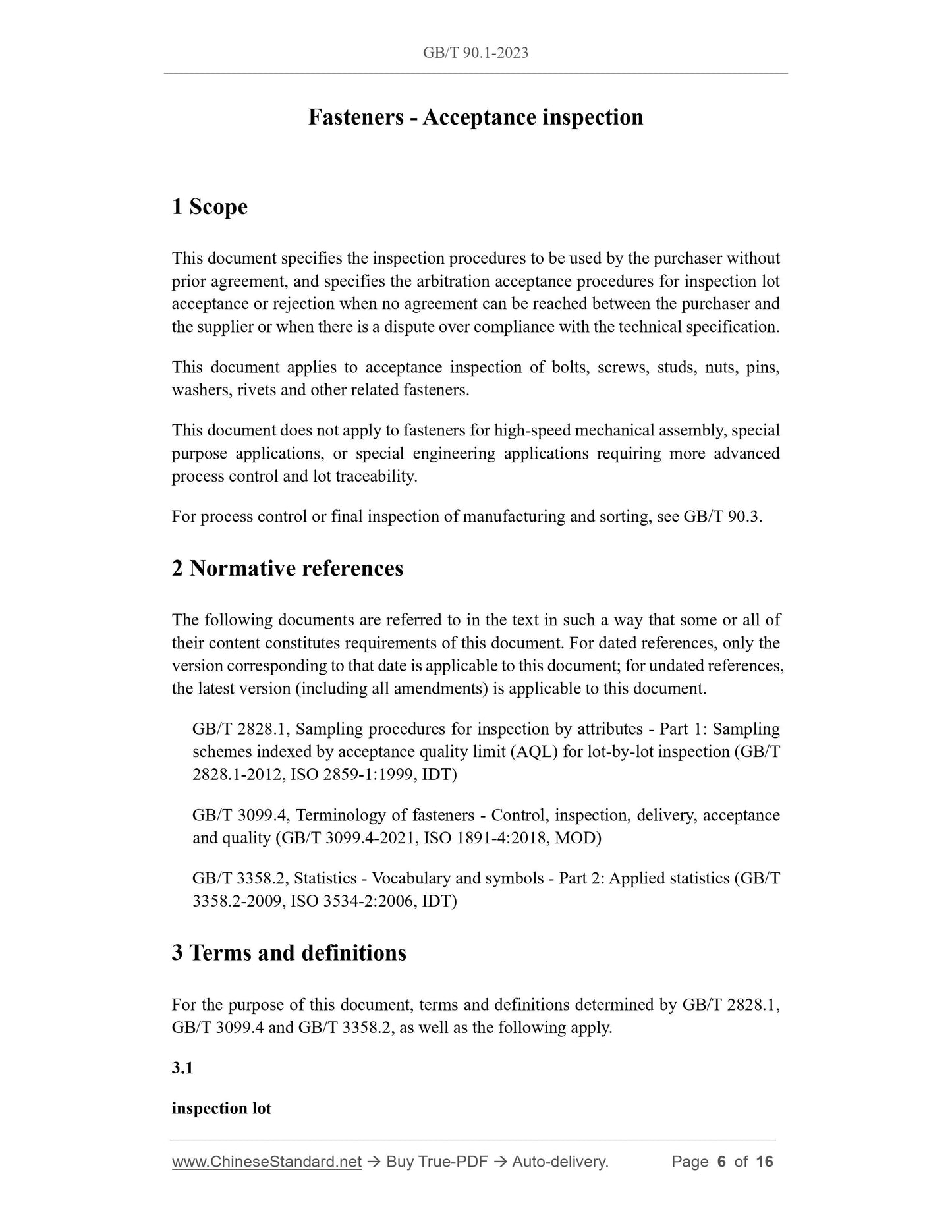

Scope

This document specifies the inspection procedures to be used by the purchaser withoutprior agreement, and specifies the arbitration acceptance procedures for inspection lot

acceptance or rejection when no agreement can be reached between the purchaser and

the supplier or when there is a dispute over compliance with the technical specification.

This document applies to acceptance inspection of bolts, screws, studs, nuts, pins,

washers, rivets and other related fasteners.

This document does not apply to fasteners for high-speed mechanical assembly, special

purpose applications, or special engineering applications requiring more advanced

process control and lot traceability.

For process control or final inspection of manufacturing and sorting, see GB/T 90.3.

Basic Data

| Standard ID | GB/T 90.1-2023 (GB/T90.1-2023) |

| Description (Translated English) | Fasteners - Acceptance inspection |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | J13 |

| Classification of International Standard | 21.060.01 |

| Word Count Estimation | 16,117 |

| Date of Issue | 2023-05-23 |

| Date of Implementation | 2023-12-01 |

| Older Standard (superseded by this standard) | GB/T 90.1-2002 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share