1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 8826-2019 English PDF (GB/T8826-2019)

GB/T 8826-2019 English PDF (GB/T8826-2019)

Regular price

$230.00

Regular price

Sale price

$230.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 8826-2019: Rubber Antioxidant - Polymerized 2,2,4-trimethyl-1,2-dihydroquinoline (TMQ)

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 8826-2019 (Self-service in 1-minute)

Newer / historical versions: GB/T 8826-2019

Preview True-PDF

Scope

This Standard specifies the classification, technical requirements, test methods,inspection rules, as well as marking, packaging, transportation and storage of rubber

antioxidant - polymerized 2,2,4-trimethyl-1,2-dihydroquinoline (hereinafter referred to

as rubber antioxidant TMQ).

This Standard is applicable to rubber antioxidant TMQ formed by polycondensation of

aniline and acetone in the presence of a catalyst.

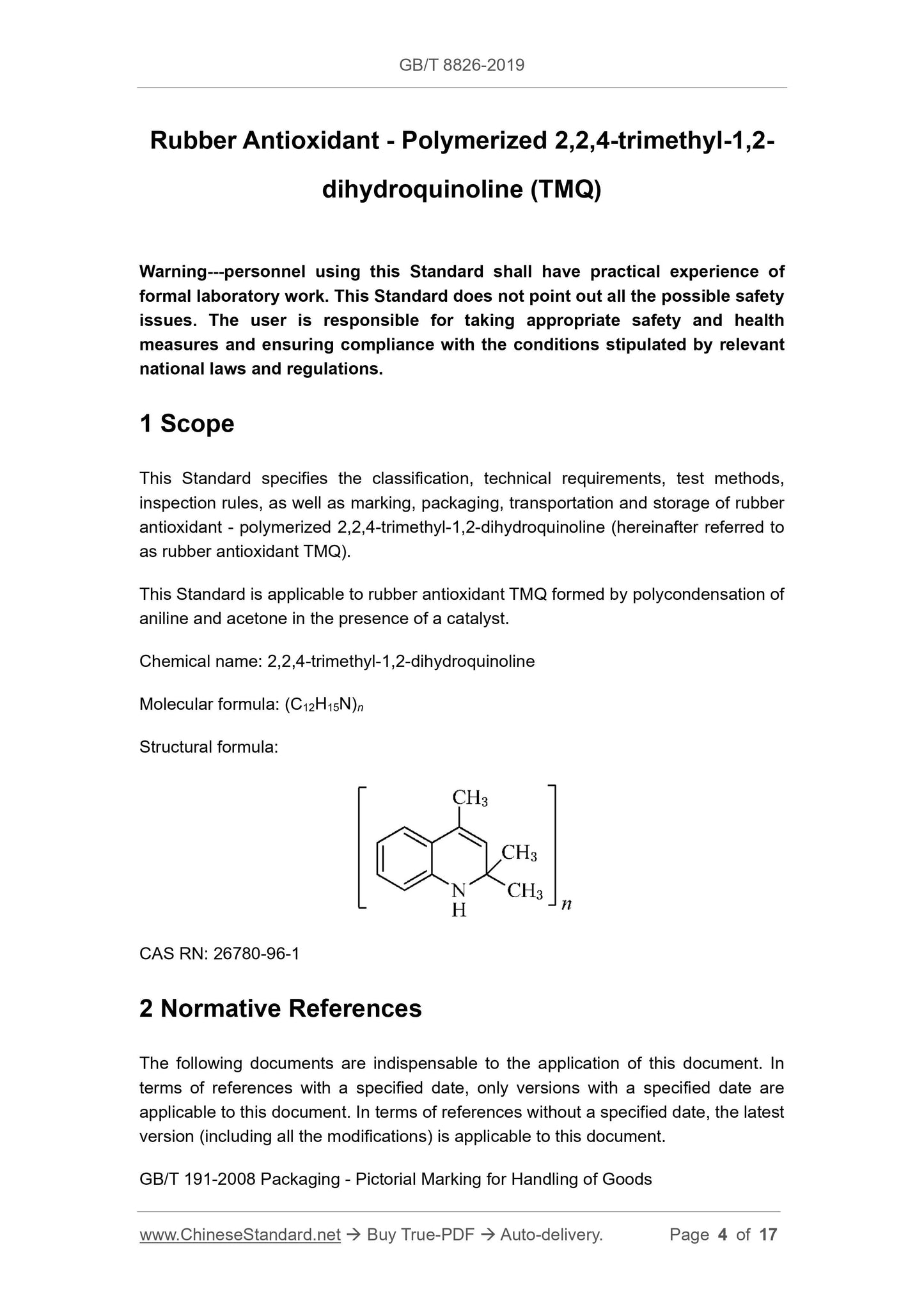

Chemical name: 2,2,4-trimethyl-1,2-dihydroquinoline

Molecular formula: (C12H15N)n

Structural formula:

CAS RN: 26780-96-1

Basic Data

| Standard ID | GB/T 8826-2019 (GB/T8826-2019) |

| Description (Translated English) | Rubber Antioxidant - Polymerized 2,2,4-trimethyl-1,2-dihydroquinoline (TMQ) |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G71 |

| Classification of International Standard | 83.040.20 |

| Word Count Estimation | 14,197 |

| Date of Issue | 2019-08-30 |

| Date of Implementation | 2020-07-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share