1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 8647.10-2006 English PDF (GB/T8647.10-2006)

GB/T 8647.10-2006 English PDF (GB/T8647.10-2006)

Regular price

$195.00

Regular price

Sale price

$195.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 8647.10-2006: The methods for chemical analysis of nickel -- Determination of arsenic cadmium lead zinc antimony bismuth tin cobalt copper manganese magnesium silicon aluminium iron contents -- Atomic emission spectrometric method

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 8647.10-2006 (Self-service in 1-minute)

Newer / historical versions: GB/T 8647.10-2006

Preview True-PDF

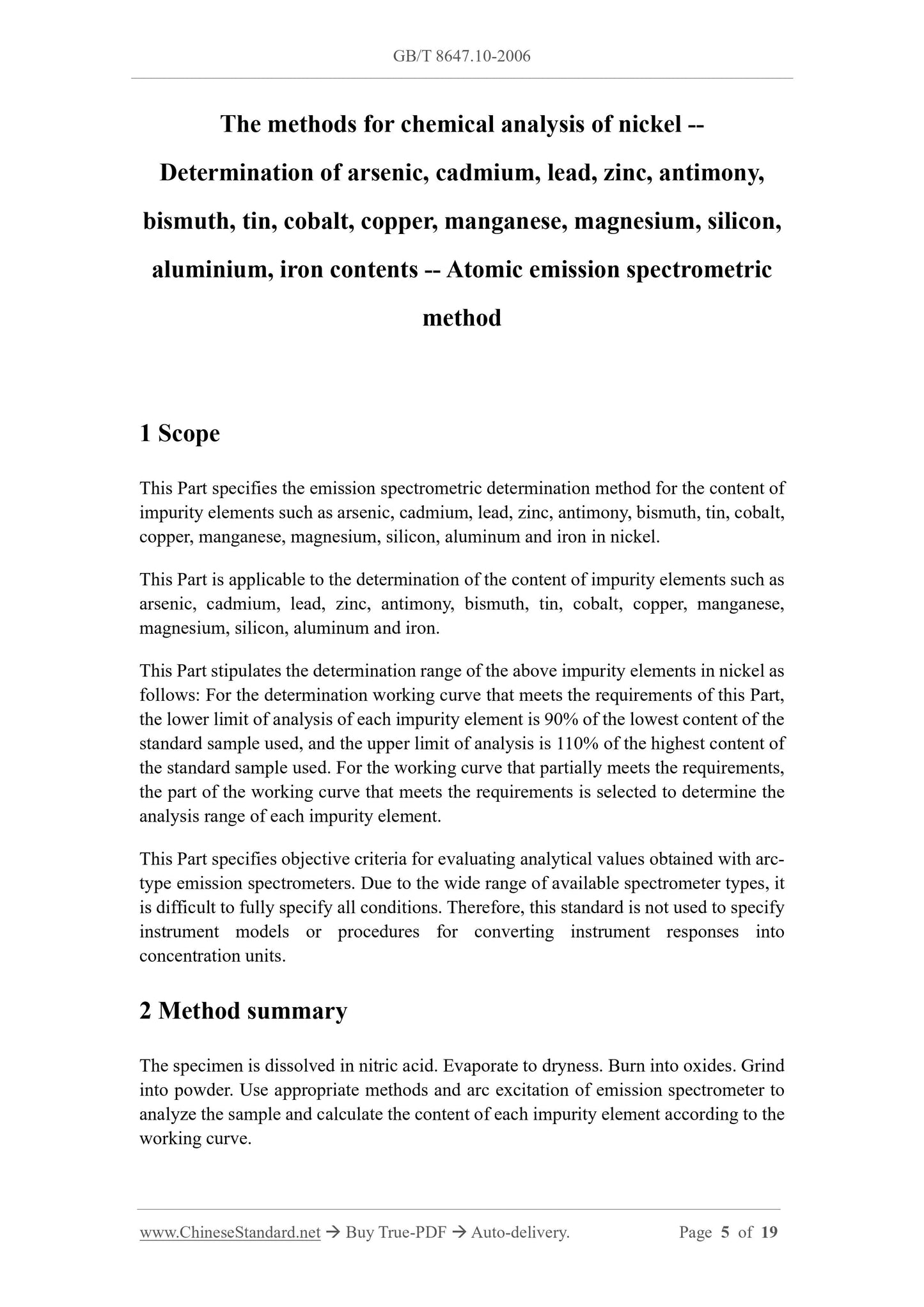

Scope

This Part specifies the emission spectrometric determination method for the content ofimpurity elements such as arsenic, cadmium, lead, zinc, antimony, bismuth, tin, cobalt,

copper, manganese, magnesium, silicon, aluminum and iron in nickel.

This Part is applicable to the determination of the content of impurity elements such as

arsenic, cadmium, lead, zinc, antimony, bismuth, tin, cobalt, copper, manganese,

magnesium, silicon, aluminum and iron.

This Part stipulates the determination range of the above impurity elements in nickel as

follows: For the determination working curve that meets the requirements of this Part,

the lower limit of analysis of each impurity element is 90% of the lowest content of the

standard sample used, and the upper limit of analysis is 110% of the highest content of

the standard sample used. For the working curve that partially meets the requirements,

the part of the working curve that meets the requirements is selected to determine the

analysis range of each impurity element.

This Part specifies objective criteria for evaluating analytical values obtained with arc-

type emission spectrometers. Due to the wide range of available spectrometer types, it

is difficult to fully specify all conditions. Therefore, this standard is not used to specify

instrument models or procedures for converting instrument responses into

concentration units.

Basic Data

| Standard ID | GB/T 8647.10-2006 (GB/T8647.10-2006) |

| Description (Translated English) | The methods for chemical analysis of nickel -- Determination of arsenic cadmium lead zinc antimony bismuth tin cobalt copper manganese magnesium silicon aluminium iron contents -- Atomic emission spectrometric method |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H13 |

| Classification of International Standard | 77.040.30 |

| Word Count Estimation | 14,175 |

| Date of Issue | 2006-09-26 |

| Date of Implementation | 2007-02-01 |

| Older Standard (superseded by this standard) | GB/T 5123-1985 |

| Regulation (derived from) | China National Standard Approval Announcement 2006 No.10 (Total No.97) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the nickel-arsenic, cadmium, lead, zinc, silicon, , aluminum, emission spectra of iron and other impurities Determination of antimony, bismuth, tin, cobalt, copper, manganese, magnesium. This section applies to a nickel arsenic, cadmium, lead, zinc, antimony, determination of iron and other impurities content, bismuth, tin, cobalt, copper, manganese, magnesium, silicon, aluminum. For the determination of the scope of the provisions of this part of the nickel content of the impurity elements are as follows: For the determination of the lower curve analysis to meet the requirements of this section, each impurity element is used by 90% of the lowest levels of standard samples, analyze the maximum limit of the standard sample using 110% of the content, localized to meet the requirements for working curve, select the curve in part to meet the requirements analysis to determine the scope of each impurity elements. This section provides an evaluation of arc-type emission spectrometer to be analyzed value objective criteria. Due to the wide existing spectrometer type, fully specified difficulties all conditions, therefore, the provisions of this section are not used to model the response of the instrument or the instrument converted to concentration units of the program. |

Share