1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 7917.2-1987 English PDF (GB/T7917.2-1987)

GB/T 7917.2-1987 English PDF (GB/T7917.2-1987)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 7917.2-1987: Standard methods of hygienic test for cosmetics. Arsenic

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 7917.2-1987 (Self-service in 1-minute)

Newer / historical versions: GB/T 7917.2-1987

Preview True-PDF

Scope

Method1.1 Method summary

After ashing or digesting of sample, by the action of potassium iodide and stannous

chloride, the pentavalent arsenic in the sample solution is reduced into trivalent. The

trivalent arsenic and nascent hydrogen generates hydrogen arsenide gas. Remove the

interference of hydrogen sulfide by the cotton dipped into the lead acetate solution,

then react with silver diethyldithiocarbamate soluble into triethanolamine-chloroform,

and generate brown red colloidal silver, then perform colorimetric analysis. The

following elements may interfere the generation of hydrogen arsenide, such as cobalt,

nickel, mercury, silver, platinum, chromium and molybdenum; but under normal

circumstances, their content in the cosmetics shall not generate the interference.

Antimony has significant interference with the determination.

1.2 Collection of sample

See Chapter 2 in GB 7917.1-87 Standard Methods of Hygienic Test for Cosmetics –

Mercury.

1.3 Reagents

1.3.1 The deionized water or water with the same purity. pure the primary distilled

water through ion-exchange water purifier, and store in the full glass bottle or

polyethylene bottle.

NOTE. such water is used during the preparation, purification and analysis of the reagent.

1.3.2 Nitric acid (density 1.42g/ml), analytically pure.

glass balls. Then add 5ml of water and 10~15ml of nitric acid (1.3.2), stand for a

moment; slowly heating; after the beginning of reaction, remove the heat source;

cooling off, add 5ml of sulfuric acid (1.3.3), continue heating. If during the digesting

period, the solution turns to brown, add a little of nitric acid to digest; repeat for several

times till the solution is clear or light-yellow. After standing and cooling off, add 20ml of

water, continue heating and boiling till white smoke is produced. Treat for twice in such

a way, move quantitative digestive solution into the 50ml volumetric flask; add water to

make constant volume, and store for backup. Every 10ml of such solution contains

sulfuric acid (1+1) of 2ml.

1.5.1.2 Dry ashing method

Weigh 1.00~2.00g of specimen mixed thoroughly, place it into 50ml porcelain

evaporating dish, meanwhile do the reagent blank; add 10ml of 10% magnesium

nitrate solution (1.3.9)①, 1g of magnesium oxide (1.3.8) powder; mix the specimen

and ashing aid thoroughly; evaporate moisture on the water bath; then charring on the

small fire till there is no smoke, move into the box-shaped electric furnace; ashing for

4h at 600°C, cool off and take out; add a little water to ash, make it wet; then add 20ml

of hydrochloric acid (1+1) (1.3.10) for several times to dissolve ash and clean

evaporating dish. Add water to make constant volume 50ml, store for backup. Every

10ml of such solution contains 2.0ml of hydrochloric acid (1+1) (excluding the

neutralized consumption).

1.5.2 Determination

Take 0, 0.50, 1.00, 2.00, 4.00, 6.00, 8.00, 10.0ml of standard arsenic solution (1.3.20),

appropriate amount of sample solution (1.5.1.1 or 1.5.1.2) and blank solution; place

them into the hydrogen arsenide generating bottle, respectively. If the sample is treated

by wet digestion method (1.5.1.1), add sulfuric acid to make the total amount of acid

equivalent to 10ml of sulfuric acid (1+1); if the sample is treated by dry ashing method

(1.5.1.2), add hydrochloric acid (1+1) to make the total amount of acid equivalent to

10ml. Then add water till the total volume is 50ml.

Add 2.5ml of 15% potassium iodide solution (1.3.11) and 2.0ml of 40% stannous

chloride solution (1.3.12), respectively, shake evenly. After standing for 10min, add

3~5g zinc particles (1.3.13); immediately connect to the air duct with lead acetate

cotton plug; and insert it into the absorption tube added 5.0ml of

silver diethyldithiocarbamate solution (1.3.12). React for 1h at the room temperature

(25°C).

After the completion of reaction, if the volume of absorption liquid is reduced,

supplement with chloroform to 5.0ml. Move partial absorption liquid into 1cm cuvette,

① The sample contains a lot oil and wax shall be modified into 1g magnesium nitrate solid.

amount of sample solution (2.5.1.1 or 2.5.1.2) and blank solution; place them into

hydrogen arsenide generating bottles, respectively; separately add 10ml of

hydrochloric acid (1+1) (2.3.10) (the sample and blank bottle shall minus the added

acid content of the added sample solution and blank solution); add water till the total

volume is 50ml. Add 2.5ml of 15% potassium iodide (1.3.11) and 2.0ml of 40%

stannous chloride solution (2.3.12), shake evenly, stand for about 10min.

Put the lead acetate cotton and lead acetate filter paper into the arsenic-measuring

tube, hold the mercury bromide test paper between the upper grounds of arsenic-

measuring tube. Pay attention that the test paper must be held tightly, and align the

aperture position.

Add 3~5g zinc particles (2.3.13) to the hydrogen arsenide generating bottle, quickly

install the arsenic-measuring tube, and plug tightly. React for 1h at the room

temperature (25°C), take off the mercury bromide test paper. Compare the arsenic

stain sample and standard arsenic stain, and quantify it.

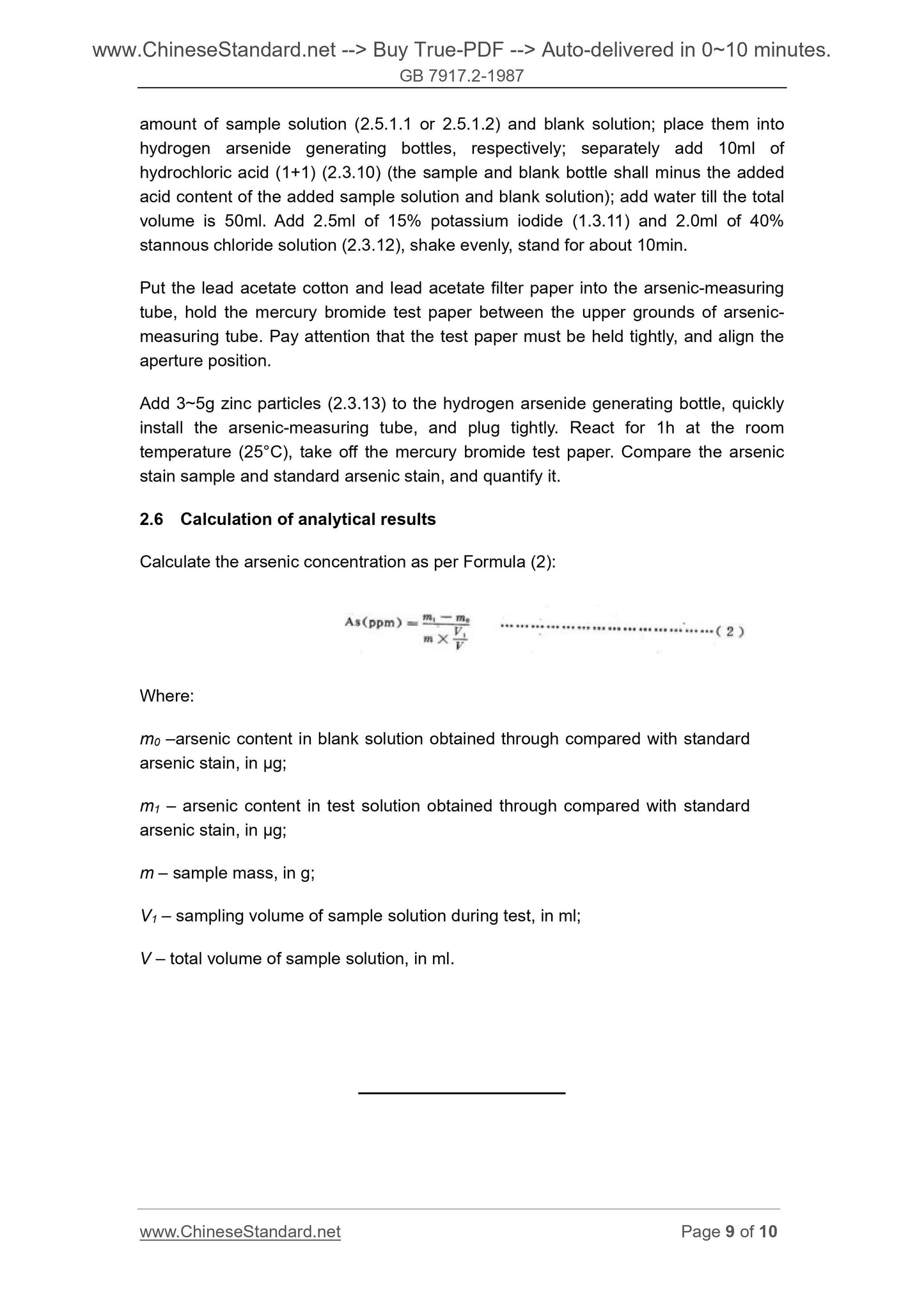

2.6 Calculation of analytical results

Calculate the arsenic concentration as per Formula (2).

Where.

m0 –arsenic content in blank solution obtained through compared with standard

arsenic stain, in µg;

m1 – arsenic content in test solution obtained through compared with standard

arsenic stain, in µg;

m – sample mass, in g;

V1 – sampling volume of sample solution during test, in ml;

V – total volume of sample solution, in ml.

Basic Data

| Standard ID | GB/T 7917.2-1987 (GB/T7917.2-1987) |

| Description (Translated English) | Standard methods of hygienic test for cosmetics. Arsenic |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | C51 |

| Classification of International Standard | 71.100.70 |

| Word Count Estimation | 5,559 |

| Date of Issue | 5/28/1987 |

| Date of Implementation | 10/1/1987 |

| Issuing agency(ies) | Ministry of Health of the People Republic of China |

| Summary | This standard applies to the determination of total arsenic in cosmetics. Both methods prescribed minimum detectable amount of 0. 5��g arsenic. If we take 1g sample measurement, the minimum detectable concentration of 0. 5ppm. |

Share