1

/

of

8

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 7184-2008 English PDF (GB/T7184-2008)

GB/T 7184-2008 English PDF (GB/T7184-2008)

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

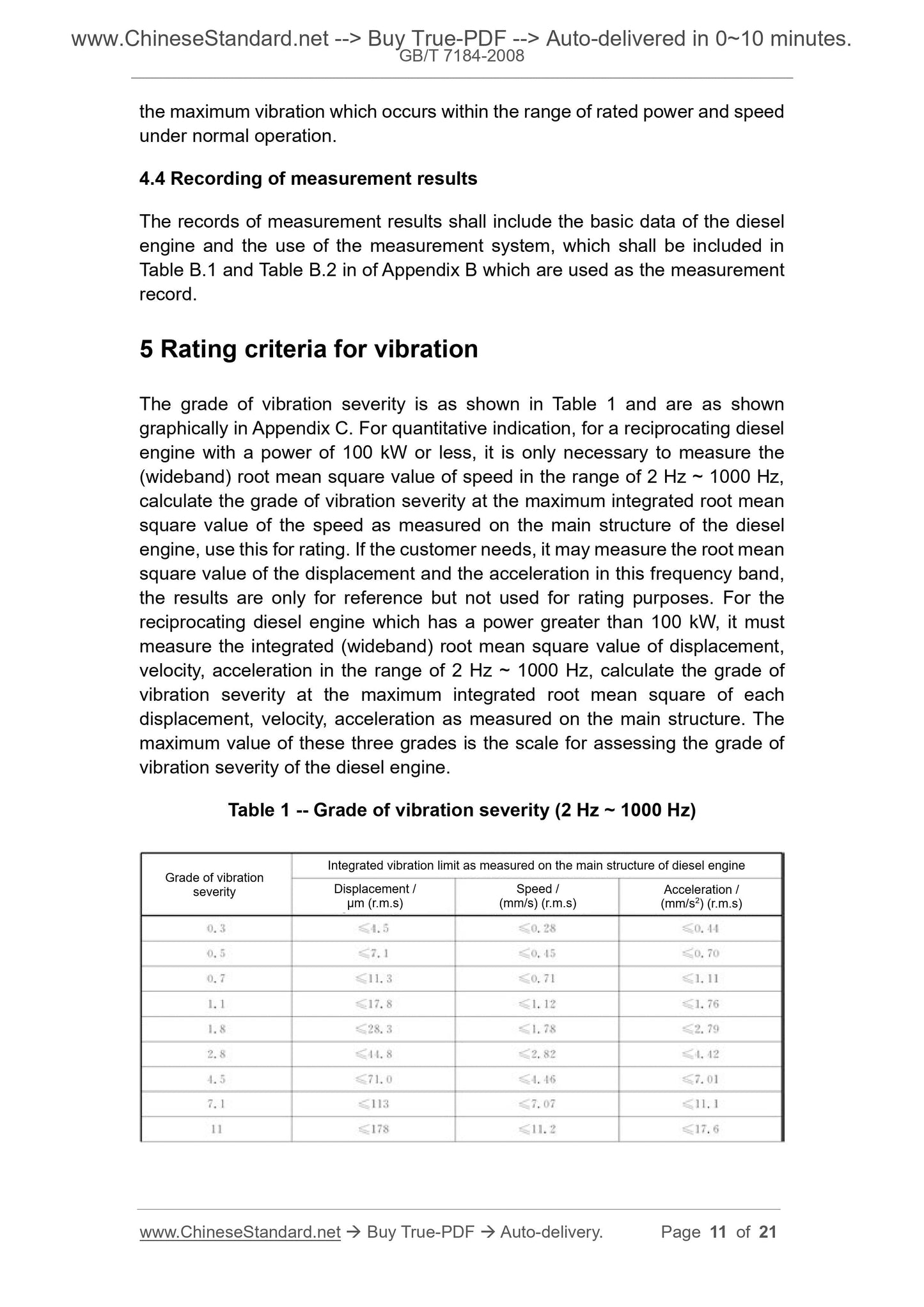

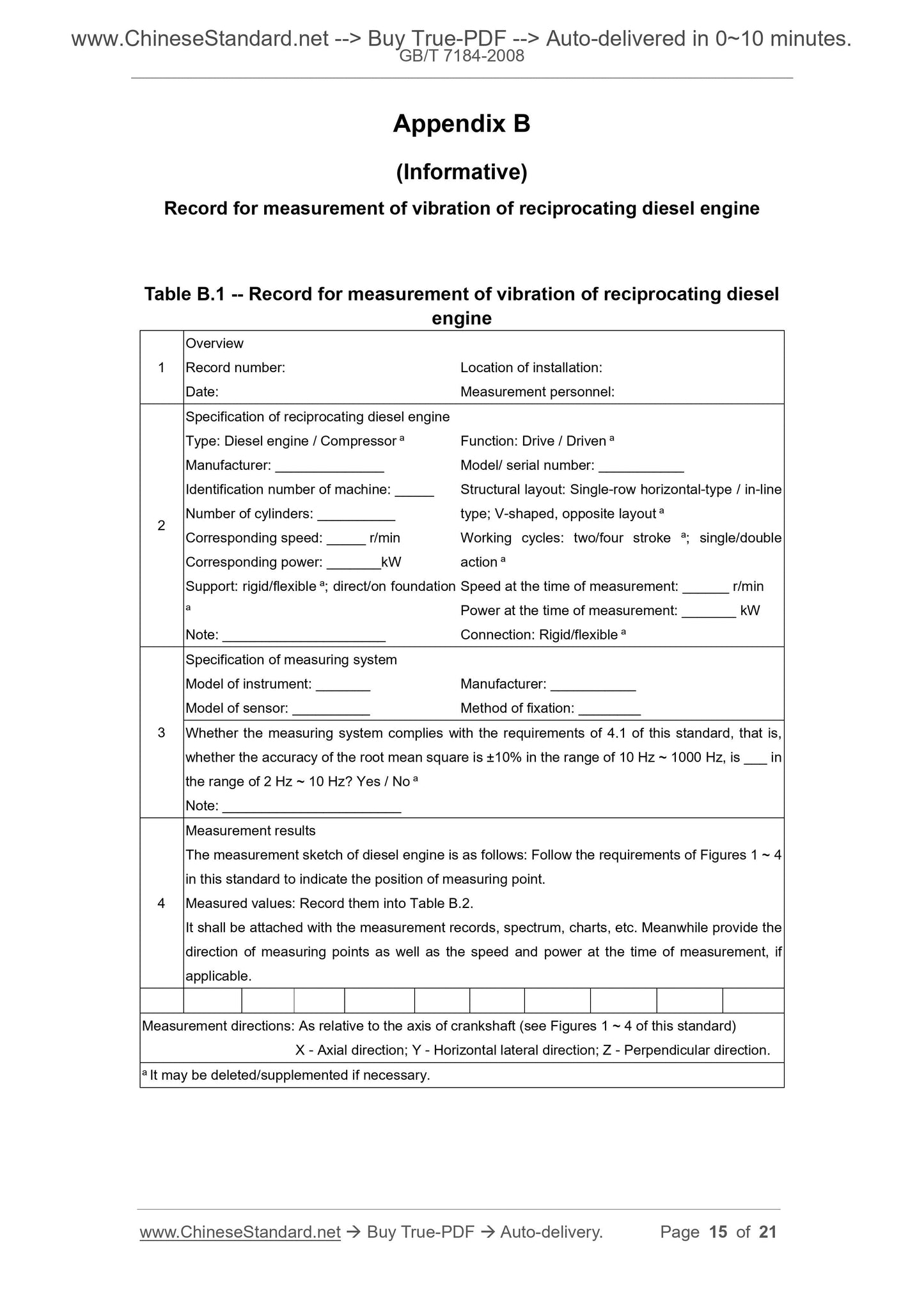

GB/T 7184-2008: Small and medium power diesel engines -- Measurement and evaluation of vibration

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 7184-2008 (Self-service in 1-minute)

Newer / historical versions: GB/T 7184-2008

Preview True-PDF

Scope

This standard specifies the measurement methods and rating criteria for thevibration of the non-rotating and non-reciprocating parts of reciprocating diesel

engines. Shaft vibrations (including torsional vibrations) are outside the scope

of this standard.

This standard is applicable to the reciprocating-piston diesel engines with rigid

or flexible support. The typical applications are diesel engines for low-speed

trucks, three-wheeled vehicles, tractors, irrigation pumps, marine main engines,

marine auxiliary engines, generator sets, etc.

This standard also applies to matched machines that are driven by

reciprocating machines or that drive reciprocating machines. For the purposes

of this, it shall follow the relevant criteria and rating for assessment.

This standard does not apply to reciprocating diesel engines which have a

power greater than 100 kW and is installed on road vehicles (such as industrial

trucks).

The rating criteria as provided by this standard apply to operational monitoring

and acceptance tests, to assess the adverse effects of mechanical vibration of

diesel engines on equipment which is directly installed on diesel engines.

The rating criteria as provided in this standard do not apply to the assessment

of internal parts of diesel engines. For example, problems related to valves,

pistons, piston rings, etc. may not be reflected in the measurement, the

identification of these problems requires the use of research techniques. The

same noise is also not within the scope of this standard.

Basic Data

| Standard ID | GB/T 7184-2008 (GB/T7184-2008) |

| Description (Translated English) | Small and medium power diesel engines -- Measurement and evaluation of vibration |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | J90 |

| Classification of International Standard | 27.020 |

| Word Count Estimation | 15,172 |

| Date of Issue | 2008-08-11 |

| Date of Implementation | 2009-02-01 |

| Older Standard (superseded by this standard) | GB/T 7184-1987; GB/T 10397-2003 |

| Quoted Standard | GB/T 2298 |

| Regulation (derived from) | National Standard Approval Announcement 2008 No.14 (Total No.127) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the methods of measurement and rating criteria for non-rotating and reciprocating diesel machine vibration of non- reciprocating parts. Shaft vibration (including torsional vibration) is not within the scope of this standard. This standard applies to rigid or flexible support of reciprocating piston engine. Typical uses for low-speed vehicles, three cars, tractor, irrigation pumps, marine host, marine auxiliary diesel engine and generator set. This standard also applies to reciprocating machines driven or driven by a reciprocating machinery supporting machines, which should be to assess the standards and classification. This standard does not apply to installation in road vehicles (such as industrial trucks) on a reciprocating engine power greater than 100kW. |

Share