1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 6508-2015 English PDF (GB/T6508-2015)

GB/T 6508-2015 English PDF (GB/T6508-2015)

Regular price

$110.00

Regular price

Sale price

$110.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

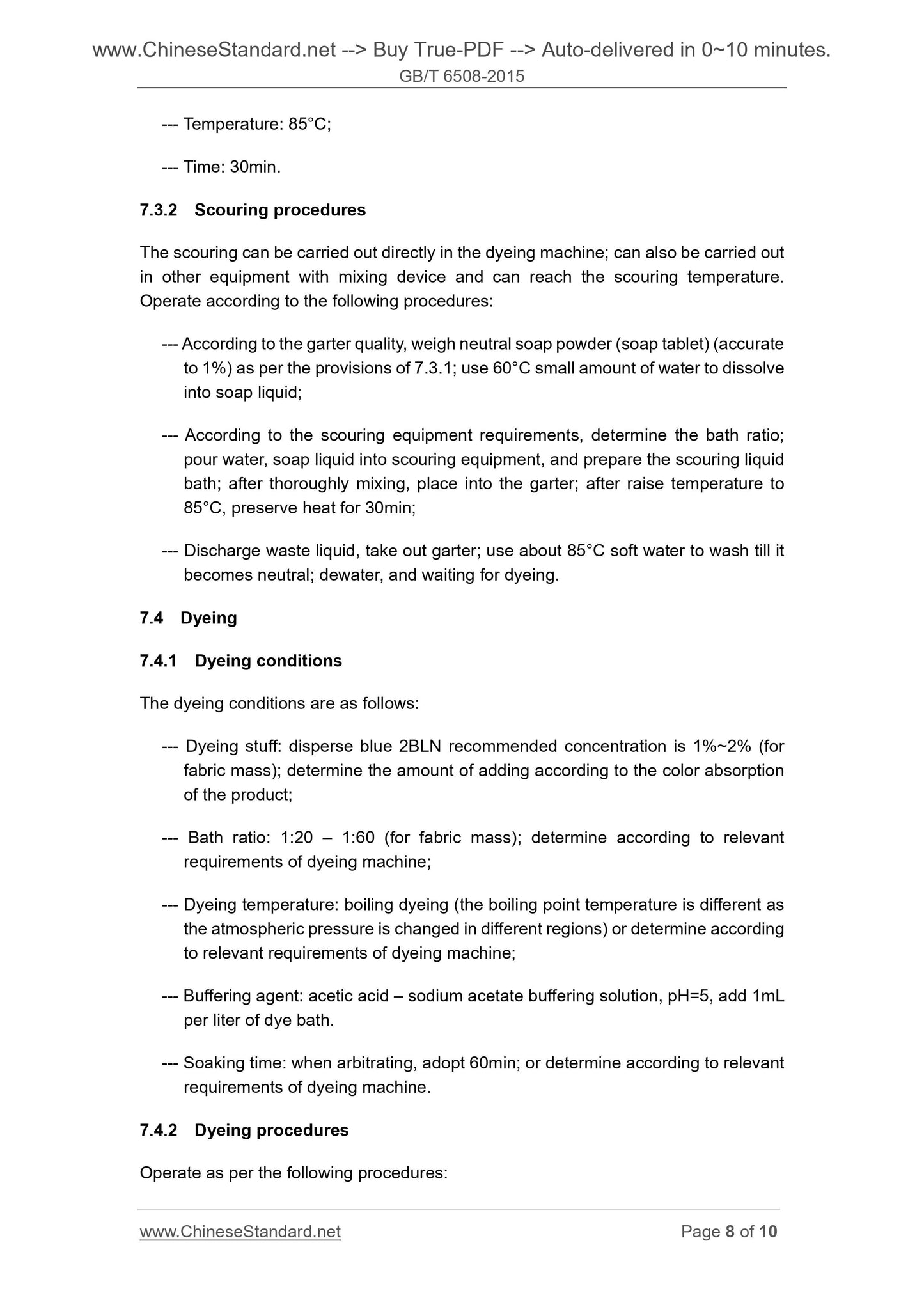

GB/T 6508-2015: Test Method for Dyeing Uniformity of Polyester Filament Yarns

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 6508-2015 (Self-service in 1-minute)

Newer / historical versions: GB/T 6508-2015

Preview True-PDF

Scope

This Standard specifies the test method for dyeing uniformity of polyester filamentyarns – hosiery dyeing method.

This Standard is applicable to draw texturing yarn and drawn yarn. Other types of

filaments can be used for reference.

Basic Data

| Standard ID | GB/T 6508-2015 (GB/T6508-2015) |

| Description (Translated English) | Test Method for Dyeing Uniformity of Polyester Filament Yarns |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | W50 |

| Classification of International Standard | 59.060.20 |

| Word Count Estimation | 8,883 |

| Date of Issue | 2015-09-11 |

| Date of Implementation | 2016-04-01 |

| Older Standard (superseded by this standard) | GB/T 6508-2001 |

| Quoted Standard | GB/T 250; GB/T 3291.1; GB/T 3291.3; GB/T 4146.1; GB/T 4146.3; GB/T 6502; GB/T 14343; FZ/T 01047 |

| Regulation (derived from) | National Standard Announcement 2015 No.25 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This Standard specifies the polyester filament yarn dyeing evenness face test method - hosiery staining. This Standard applies to DTY and FDY. Other types of filaments can refer to use. |

Share